The Rise of Micro Centerless Grinders Innovations in Precision Manufacturing

In the world of precision manufacturing, the advent of micro centerless grinders has significantly transformed the landscape of small-scale component production. The demand for ultra-fine tolerances in various industries, including medical devices, automotive parts, and electronics, has spurred manufacturers to refine their processes. This article will delve into the unique characteristics, operational principles, and advantages of micro centerless grinders, shedding light on their crucial role in modern manufacturing.

Understanding Micro Centerless Grinding

Micro centerless grinding is an advanced machining process that allows for the grinding of small-diameter workpieces without the need for complex setups. Unlike traditional grinding methods, which often require elaborate fixturing, the micro centerless grinder utilizes a simple yet effective design that holds the workpiece between a rotating grinding wheel and a regulating wheel. This configuration enables the workpiece to be ground uniformly and efficiently, producing components with minimal surface roughness and precise dimensions.

The primary components of a micro centerless grinder include the grinding wheel, the regulating wheel, and the workpiece support. The grinding wheel, typically made from a composite material, is responsible for material removal. The regulating wheel, often made of a softer material, helps control the speed and position of the workpiece during the grinding process. The ability to adjust the speed and pressure applied by the regulating wheel allows for fine-tuning of the machining process, making it suitable for various materials and geometries.

Applications and Industries

Micro centerless grinders are widely utilized across numerous industries due to their versatility and precision. In the medical device industry, for instance, the production of components such as guidewires, catheters, and surgical instruments demands exceptional accuracy. The ability to achieve tight tolerances and smooth finishes makes micro centerless grinding an ideal solution for these applications.

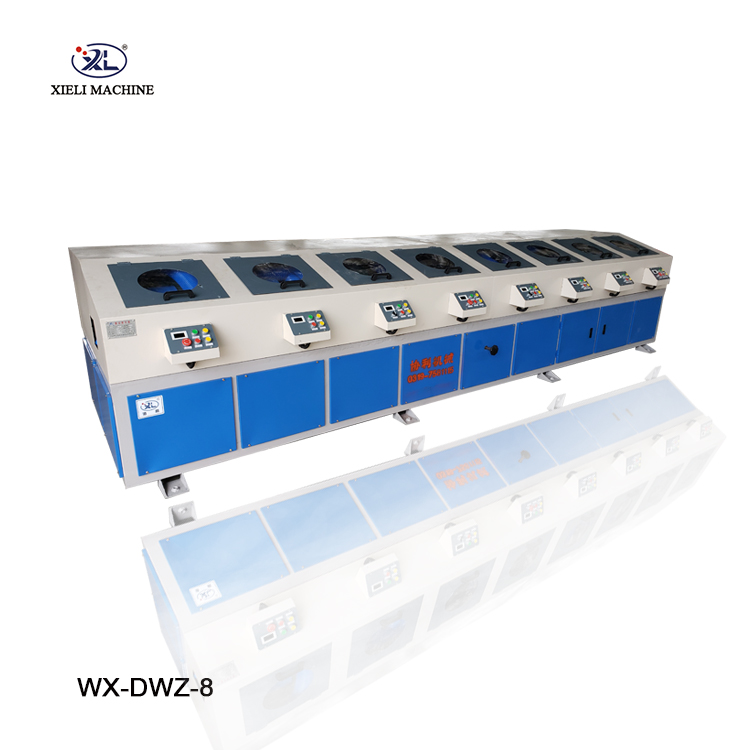

micro centerless grinder factory

In the automotive sector, micro centerless grinders are employed to produce precision components like fuel injection parts and valve stems. The need for lightweight, durable components that can withstand high pressures and temperatures drives the demand for such advanced manufacturing techniques. Similarly, in the electronics industry, micro centerless grinding is used to create intricate parts for connectors and sensors.

Advantages of Micro Centerless Grinding

One of the most significant advantages of micro centerless grinders is their efficiency. By eliminating the need for intricate setups and fixtures, manufacturers can significantly reduce downtime and increase productivity. Parts can be ground quickly and accurately, allowing for higher throughput and faster delivery to customers.

Moreover, micro centerless grinding produces minimal waste. The precise nature of the process results in less material being removed compared to other methods, which not only saves costs but also contributes to environmentally friendly manufacturing practices. Additionally, the consistency of the grinding process helps to minimize variations in component dimensions, leading to improved quality control.

Another notable benefit is the flexibility offered by micro centerless grinders. These machines can accommodate a broad range of materials, from soft metals to hard alloys, making them suitable for various applications. Manufacturers can easily adjust parameters such as grinding speeds and feed rates to optimize the process for different types of workpieces.

Conclusion

As industries continue to push the boundaries of precision and efficiency, micro centerless grinding stands out as an essential technology in the world of manufacturing. With its ability to produce small-diameter components with unparalleled accuracy, it plays a pivotal role in several high-demand sectors, including medical, automotive, and electronics. The ongoing advancements in micro centerless grinder technology promise even greater capabilities, ensuring that this machining process will remain at the forefront of precision manufacturing for years to come. Embracing these innovative solutions enables manufacturers to meet the evolving demands of their industries while enhancing productivity and product quality.