Metal Tube Polishing Machine Factories An Overview

In the landscape of modern manufacturing, the importance of high-quality finishes on metal products cannot be overstated. Among the various processes that contribute to the final appearance and functionality of metal products, polishing stands out as a critical step. Metal tube polishing machines play a vital role in this industry, and their factories cater to a diverse range of applications and requirements.

Metal tube polishing machines are designed to enhance the surface finish of various types of metal tubes, including stainless steel, aluminum, and other alloys. The primary purpose of these machines is to remove imperfections, such as scratches, oxidation, and dirt, while simultaneously improving the aesthetic appeal of the tubes. This process is crucial in industries such as automotive, aerospace, medical, and food processing, where hygiene and presentation are paramount.

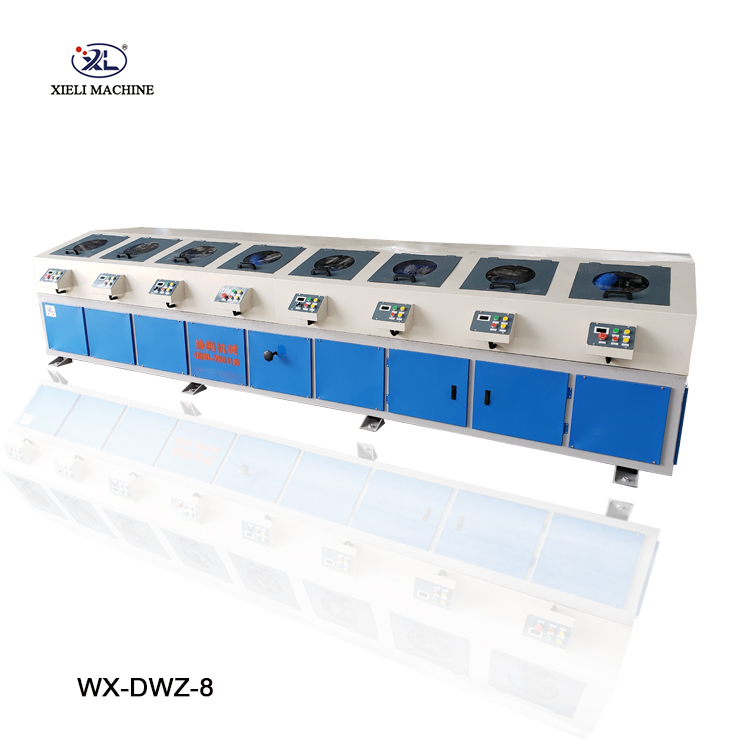

The factories that manufacture metal tube polishing machines utilize advanced technologies and engineering techniques to create equipment that meets the ever-evolving demands of the industry. These factories typically specialize in designing and producing different types of polishing machines, including mechanical, magnetic, and chemical polishing systems. Each type of machine has its own set of advantages and is suited for specific applications, allowing manufacturers to choose the right equipment based on their requirements.

One of the key factors influencing the choice of a metal tube polishing machine is its efficiency. Modern factories focus on producing machines that not only provide superior polishing results but also operate with remarkable speed and precision. This efficiency translates to lower operational costs and enhanced productivity for manufacturers, allowing them to remain competitive in a fast-paced market.

metal tube polishing machine factories

In addition to efficiency, sustainability is an increasingly important aspect of manufacturing processes. Many metal tube polishing machine factories are adopting eco-friendly practices, such as implementing closed-loop systems that minimize waste and recycling polishing compounds. These practices not only contribute to environmental conservation but can also result in cost savings for manufacturers in the long run.

Quality control is another crucial element in the production of metal tube polishing machines. Factories employ rigorous testing protocols to ensure that their machines meet industry standards and customer specifications. This commitment to quality helps establish trust with clients and ensures that end products consistently meet or exceed their expectations.

The global demand for metal tube polishing machines is on the rise, driven by the expansion of various industries and an increasing focus on product aesthetics and performance. As a result, factories are often looking to innovate and expand their offerings. This includes developing machines with smart technology features, such as automated controls and real-time monitoring systems that allow for greater customization and adaptability in the polishing process.

In conclusion, metal tube polishing machine factories play a critical role in enhancing the quality and appeal of metal products across numerous industries. By focusing on efficiency, sustainability, and quality control, these factories are not only meeting the demands of today's market but also paving the way for future advancements in metal finishing technologies. As industries continue to evolve, the importance of these factories and the machines they produce will undoubtedly grow.