The Rise of Metal Tube Polishing Machine Exporters A Comprehensive Overview

In the ever-evolving landscape of industrial machinery, metal tube polishing machines have emerged as vital equipment for various industries, including automotive, aerospace, furniture, and construction. The growing demand for high-quality polished metal products has stimulated a robust market for exporters in this sector. This article delves into the significance of metal tube polishing machines, the role of exporters, and the trends shaping the industry.

Understanding Metal Tube Polishing Machines

Metal tube polishing machines are used to enhance the surface finish of metal tubes, ensuring they meet specific aesthetic and functional requirements. These machines are designed to remove surface imperfections, oxidation, and contaminants while improving corrosion resistance. Common applications of polished metal tubes include structural elements in buildings, components in vehicles, and parts in machinery that require not only functionality but also visual appeal.

The operation of these machines typically involves various polishing processes that utilize abrasives, chemicals, and mechanical actions. Advanced technologies, such as automated systems and robotic arms, are increasingly being integrated into metal tube polishing machines to enhance efficiency and accuracy. As manufacturers strive to meet stringent quality standards and increase production capacity, the demand for high-performance polishing machines continues to grow.

The Role of Exporters in the Industry

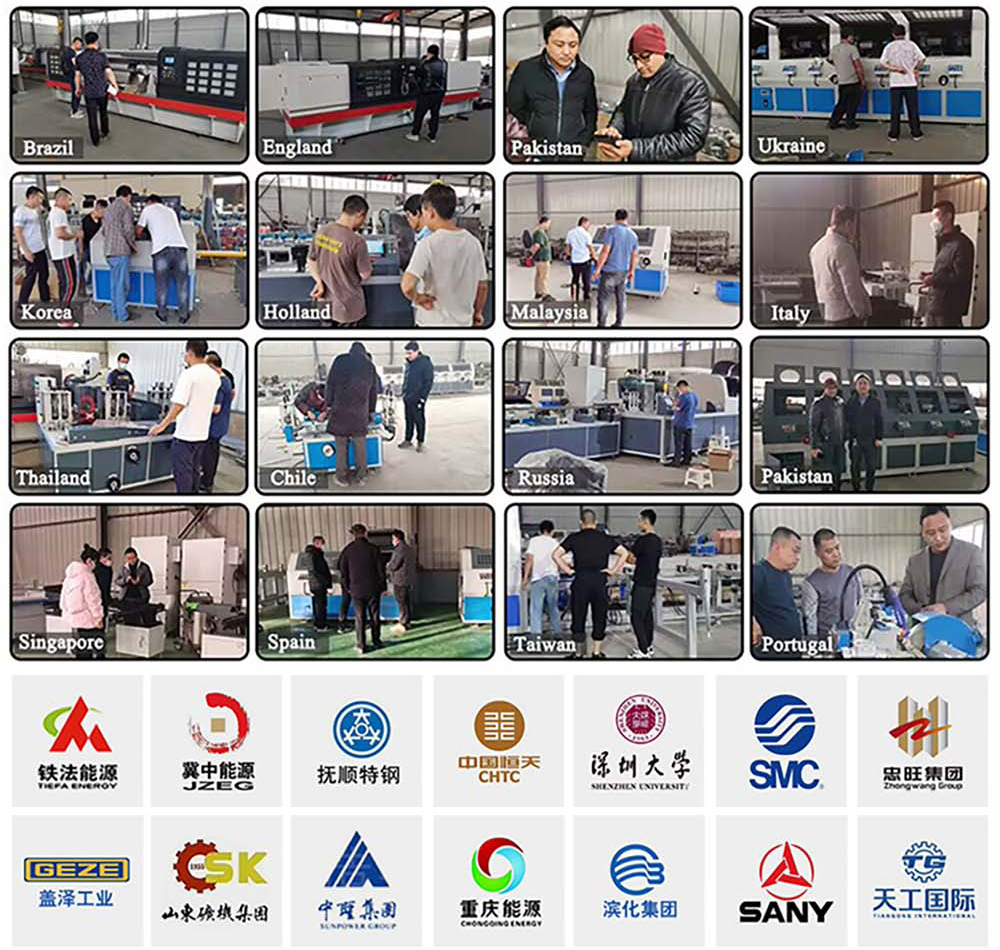

Exporters play a crucial role in connecting manufacturers of metal tube polishing machines with global markets. They are responsible for navigating various international trade regulations, logistics, and market trends to ensure that machines reach various industries across the globe. Here's a closer look at the key functions of metal tube polishing machine exporters

1. Market Reach Exporters help manufacturers expand their market reach beyond domestic borders. By providing insights into international demand and customer preferences, they assist companies in tailoring their products for specific markets.

2. Compliance and Regulations International markets often have unique compliance standards and safety regulations. Exporters help manufacturers understand and adhere to these requirements, ensuring that their products can be marketed globally without facing legal challenges.

3. Logistics and Shipping Exporting machinery involves complex logistics, including shipping, customs clearance, and delivery coordination. Exporters have established networks and expertise to handle these processes efficiently, reducing the time and costs associated with international trade.

metal tube polishing machine exporters

4. Customer Support and Service Post-sale support is crucial for maintaining customer satisfaction. Exporters often facilitate technical support and spare parts supply, ensuring that customers can effectively use and maintain their polishing machines.

Trends Influencing the Export Market

Several trends are influencing the metal tube polishing machine export market

1. Technological Advancements With the continuous evolution of technology, manufacturers and exporters focus on developing and integrating advanced features into polishing machines, such as smart sensors, IoT connectivity, and AI-driven processes to improve operational efficiency.

2. Sustainability As industries face increasing pressure to adopt sustainable practices, exporters are seeking eco-friendly solutions. This includes promoting machines that utilize less energy, produce less waste, and incorporate recyclable materials.

3. Market Diversification Countries in emerging markets are witnessing a surge in manufacturing activities, creating new opportunities for exporters. Nations in Asia-Pacific, Latin America, and Africa are becoming significant players, prompting exporters to explore these regions.

4. Customization Industrial clients often require specialized machines tailored to their specific needs. Exporters are increasingly offering customized solutions, allowing manufacturers to cater to niche markets and enhance their competitive edge.

Conclusion

The market for metal tube polishing machine exporters is poised for growth as industries increasingly recognize the importance of high-quality metal products. By facilitating trade, ensuring compliance, and providing valuable customer support, exporters play a pivotal role in the success of manufacturers in this dynamic industry. As technology advances and global demand evolves, the metal tube polishing machine export sector will likely flourish, adapting to emerging trends and maximizing opportunities worldwide.