Exploring the Global Market for Metal Tube Polishing Machine Exporters

In today's industrial landscape, the significance of polished metal products cannot be overstated. Industries ranging from automotive to aerospace, medical to construction, rely heavily on polished metal components for both aesthetic and functional purposes. As a result, the demand for metal tube polishing machines has surged, positioning exporters in this field at a pivotal intersection of manufacturing and innovation. This article delves into the world of metal tube polishing machine exporters, examining the factors that drive their success and the challenges they face in a competitive global market.

The Importance of Metal Tube Polishing

Metal tube polishing is a crucial process that enhances the surface finish of metal tubes. These tubes serve various functions, including structural support, fluid transportation, and as components in machinery. A well-polished surface not only increases the visual appeal of these products but also improves their resistance to corrosion, facilitates easier cleaning, and enhances overall performance. Thus, industries are increasingly investing in advanced polishing machines to meet these needs, creating a burgeoning market for exporters of these specialized machines.

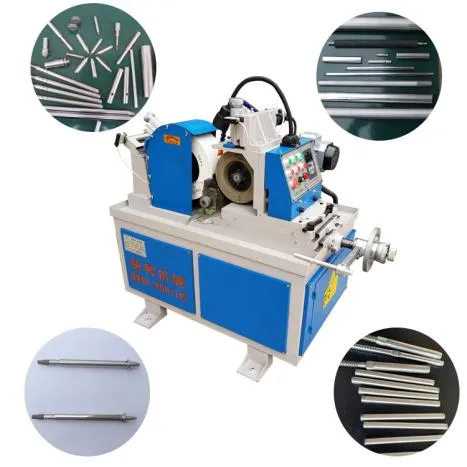

Key Features of Metal Tube Polishing Machines

Modern metal tube polishing machines come equipped with a range of features designed to optimize performance and efficiency. These machines often utilize advanced technologies such as automated controls, variable speed settings, and multi-head polishing capabilities. As a result, they can cater to diverse requirements ranging from small-scale operations to large-scale manufacturing. Additionally, the integration of robotics and artificial intelligence in some machines has further increased precision and reduced the time needed for polishing, making them attractive investments for manufacturers worldwide.

Export Market Trends

The global market for metal tube polishing machines is witnessing significant growth, driven by increasing industrialization and the rise in manufacturing activities across various sectors. Countries with strong manufacturing bases, such as China, Germany, and the United States, are leading exporters in this arena. Moreover, emerging markets in Asia, Africa, and Latin America are also stepping up their production capacities, creating new opportunities for businesses involved in exporting these machines.

metal tube polishing machine exporter

Trade agreements and globalization have further facilitated the expansion of this market. Exporters can now reach a broader audience, relying on e-commerce platforms and digital marketing strategies to connect with potential buyers worldwide. Additionally, participation in international trade fairs and exhibitions has proven advantageous for many exporters, allowing them to showcase their machines and establish valuable contacts.

Challenges Faced by Exporters

Despite the promising growth prospects, metal tube polishing machine exporters face several challenges. One significant hurdle is the variations in regulatory standards across different countries. Exporters must navigate complex compliance requirements, ensuring their machines meet safety and quality standards specific to each market. Failure to comply can lead to severe penalties and loss of reputation.

Furthermore, maintaining competitive pricing is challenging in a market where innovation occurs at a rapid pace. Exporters must continually invest in research and development to enhance their machines' features and efficiency, all while managing production costs. This balancing act can strain resources, particularly for smaller exporters.

The Future of Metal Tube Polishing Machine Exporters

Looking ahead, the future for metal tube polishing machine exporters appears bright. Innovations in technology, such as the development of environmentally friendly polishing methods and the incorporation of smart technology, will likely drive demand. Additionally, as industries increasingly prioritize sustainability, exporters that adapt to these trends will find themselves ahead of the curve.

In conclusion, the role of metal tube polishing machine exporters is critical in meeting the growing demands of various industrial sectors. With continued investment in technology and adaptability to changing market conditions, exporters can position themselves for sustained growth in this dynamic global market. Emphasizing quality, efficiency, and compliance will be key for success, ensuring they remain vital players in the machinery and manufacturing landscape. As industries evolve, so too will the opportunities for those willing to innovate and expand their reach.