The Importance of Metal Tube Polishing Machines in Modern Manufacturing

In the realm of modern manufacturing, the appearance and finish of products are as crucial as their functionality. Among various processes that enhance these attributes, metal tube polishing has emerged as a critical step. Metal tube polishing machines play an essential role in achieving a high-quality finish on metal tubes used in various industries, including automotive, aerospace, medical, and construction. This article explores the importance, functionality, and benefits of metal tube polishing machines.

Understanding Metal Tube Polishing

Metal tube polishing refers to the process of smoothing and shining metal tubes through mechanical means. The primary objective is to remove surface imperfections, enhance corrosion resistance, and improve the aesthetic appeal of the tubes. Polished metal tubes are not only visually appealing but also exhibit superior performance characteristics, making them suitable for high-demand applications.

The Functionality of Polishing Machines

Metal tube polishing machines come in various types, each designed to cater to specific requirements. The most common types include manual polishing machines, semi-automatic machines, and fully automatic systems. Each machine incorporates various techniques, such as mechanical polishing, electro-polishing, and abrasive polishing, tailored to different metals such as stainless steel, aluminum, and copper.

The machinery often utilizes a combination of rotary brushes, buffing wheels, and abrasive materials that effectively remove oxides, rust, and scale from the metal surface. Automation features in advanced polishing machines enhance efficiency by allowing consistent results, reducing labor costs, and minimizing the risk of human error.

Benefits of Using Metal Tube Polishing Machines

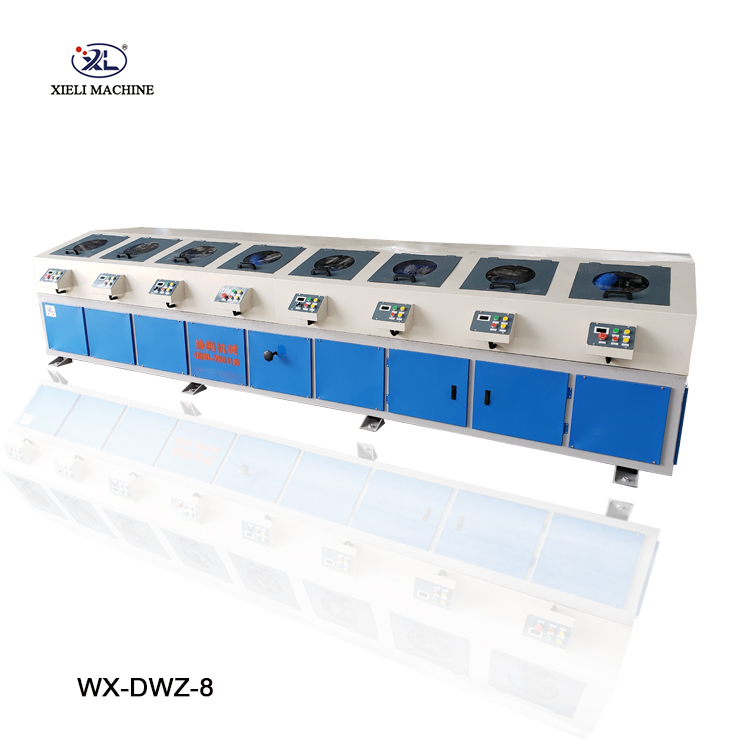

metal tube polishing machine

1. Enhanced Aesthetic Appeal Polished metal tubes have a bright, reflective surface that is visually appealing. This quality is particularly important in industries where aesthetics play a crucial role, such as architecture and design.

2. Increased Corrosion Resistance The polishing process often creates a smoother surface, which can significantly enhance the metal's resistance to corrosion. This is particularly beneficial in applications where tubes are exposed to harsh environmental conditions.

3. Improved Performance A polished surface often translates to lower friction coefficients, which is essential in applications involving fluid transfer. Improved hydrodynamics lead to better flow rates and energy efficiency.

4. Durability A high-quality finish can extend the lifespan of metal tubes. By minimizing the accumulation of debris and pollutants, polished tubes are less likely to suffer from wear and tear over time.

5. Cost-effective Production Investing in modern metal tube polishing machines can lead to significant cost savings in the long run. Automation streamlines operations, reduces manual labor, and speeds up production time while maintaining high quality.

Conclusion

As industries continue to evolve, the demand for high-quality, aesthetically pleasing metal products grows. Metal tube polishing machines are at the forefront of this trend, offering businesses a way to enhance their products' appearance and performance. With advancements in technology, these machines are becoming more efficient and versatile, making them essential tools for manufacturers aiming to remain competitive in a rapidly changing market.

Overall, the importance of metal tube polishing machines cannot be overstated. They not only contribute to the visual and functional quality of metal products but also play a pivotal role in ensuring that industries can meet the evolving demands of their customers. Investing in a reliable polishing machine is not just a choice but a necessity for manufacturers committed to excellence in their products.