The Importance of Metal Surface Polishing Machines in Modern Manufacturing

In the realm of modern manufacturing, metal surface polishing machines have become crucial tools that significantly enhance both the aesthetic and functional qualities of metal products. These machines are essential for providing smooth, uniform surfaces on metal components that are critical in various industries, including automotive, aerospace, electronics, and furniture. By utilizing advanced technology, metal surface polishing machines improve the quality of finished products, contributing to both their appearance and performance.

The Process of Metal Surface Polishing

The primary function of metal surface polishing machines is to remove imperfections, scratches, and oxidation from the surface of metal items. This process not only improves the visual appeal of the metal but also increases its resistance to corrosion and wear. There are several methods employed in metal polishing, including mechanical polishing, chemical polishing, and electro-polishing.

Mechanical polishing typically involves the use of abrasive materials and tools, such as belts, pads, or wheels. With the right combination of pressure, speed, and abrasive material, operators can achieve a high-gloss finish that satisfies stringent industry standards. On the other hand, chemical and electro-polishing methods utilize chemical baths and electrical charges to smooth and passivate the metal surfaces. These methods are particularly effective for complex geometries where mechanical polishing might not be feasible.

Benefits of Using Metal Surface Polishing Machines

1. Enhanced Aesthetic Appeal One of the most immediate benefits of polishing is the lustrous finish it provides to metal surfaces. This is particularly important in industries where the look of the product is paramount, such as in decorative hardware, jewelry, and high-end consumer electronics.

2. Improved Performance Polished surfaces are smoother, allowing for better fluid flow in pipes and reduced friction in moving parts. This is vital in industries like automotive and aerospace, where the efficiency and longevity of components directly impact performance and safety.

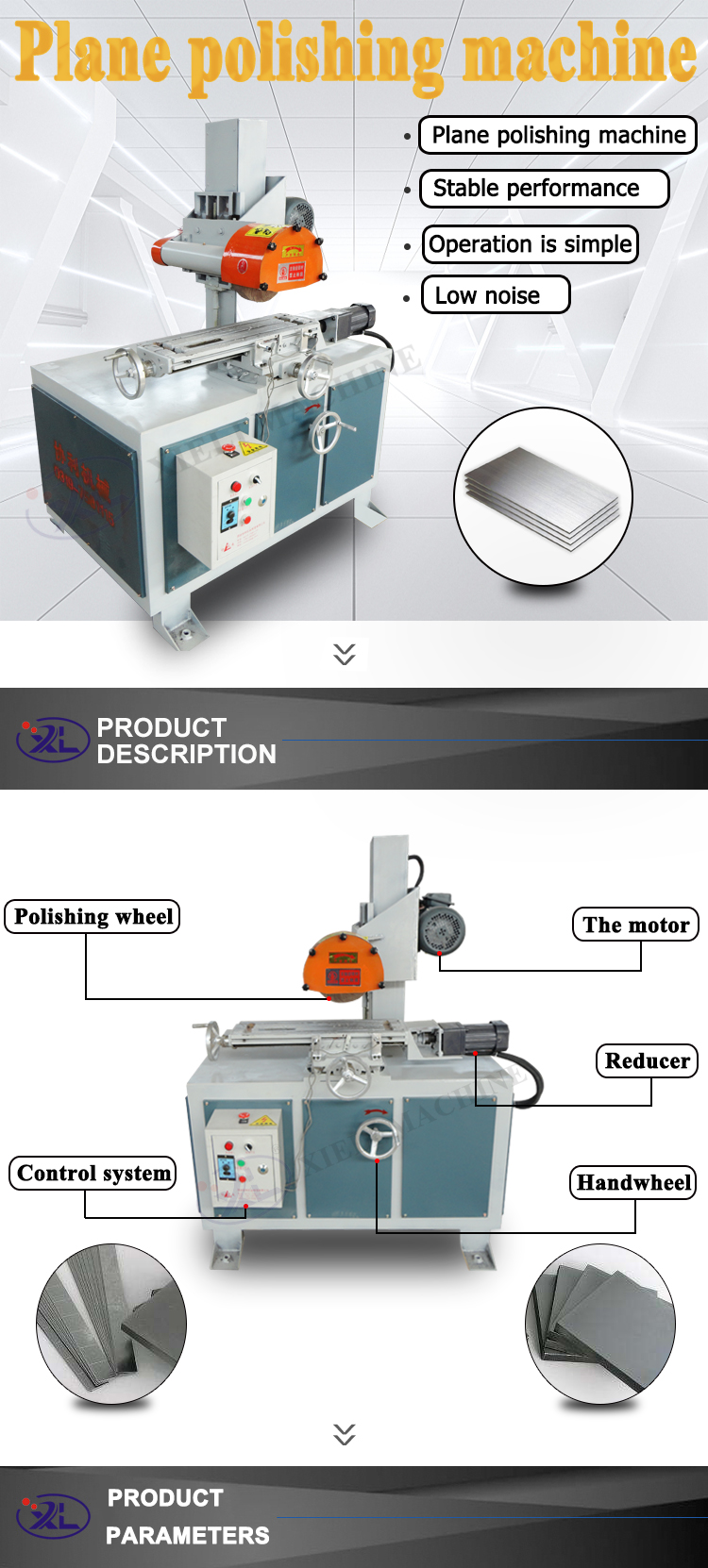

metal surface polishing machine product

3. Increased Durability By minimizing the surface imperfections that can harbor corrosive agents, polishing can greatly enhance the lifespan of metal products. Specialized polishing machines can also create surface finishes that are resistant to scratches, chemical damage, and other forms of wear.

4. Higher Quality Standards With the rise of global competition, maintaining high quality is more critical than ever. Metal surface polishing machines enable manufacturers to meet and exceed industry standards, ensuring their products are both functional and aesthetically pleasing.

5. Automation and Efficiency Many modern polishing machines are equipped with automation features that reduce labor costs and time while increasing precision and consistency. Automated processes can handle large volumes and complex shapes more efficiently than manual polishing.

Choosing the Right Polishing Machine

When considering a metal surface polishing machine, manufacturers must take into account several factors such as the type of metal being polished, the desired finish, production volume, and budget. There are many different models and configurations available on the market, from small bench-top units suitable for hobbyists to large industrial machines designed for high-volume manufacturing.

Investing in a quality polishing machine can yield significant returns in product quality, manufacturing efficiency, and customer satisfaction. It is essential to research and select a machine that aligns with specific production requirements while also keeping in mind the future scalability of operations.

Conclusion

Metal surface polishing machines are a vital aspect of the manufacturing process in a variety of industries. They not only enhance the appearance and performance of metal products but also contribute to improved durability and compliance with quality standards. As technology continues to evolve, the capabilities and efficiency of these machines will likely improve, paving the way for even greater innovations and advancements in metal manufacturing. Manufacturers who prioritize investing in high-quality polishing equipment will find themselves at a competitive advantage in an increasingly demanding market.