Exploring Metal Surface Polishing Machine Factories Achieving Perfection in Finishing

In the realm of manufacturing, the quest for perfection is an ongoing journey, especially when it comes to the finishing processes of metal products. One of the most critical aspects of this journey is the use of metal surface polishing machines. These specialized machines are designed to enhance the aesthetic appeal of metal surfaces while also improving their functional performance. As the demand for high-quality finishes grows across various industries, the significance of metal surface polishing machine factories becomes increasingly prominent.

Understanding Metal Surface Polishing Machines

Metal surface polishing machines are designed to refine and smooth metal surfaces to a high sheen, removing imperfections and burrs that may be present after fabrication. These machines come in various types, including manual, semi-automatic, and fully automatic models, each catering to different needs based on the production scale and quality requirements.

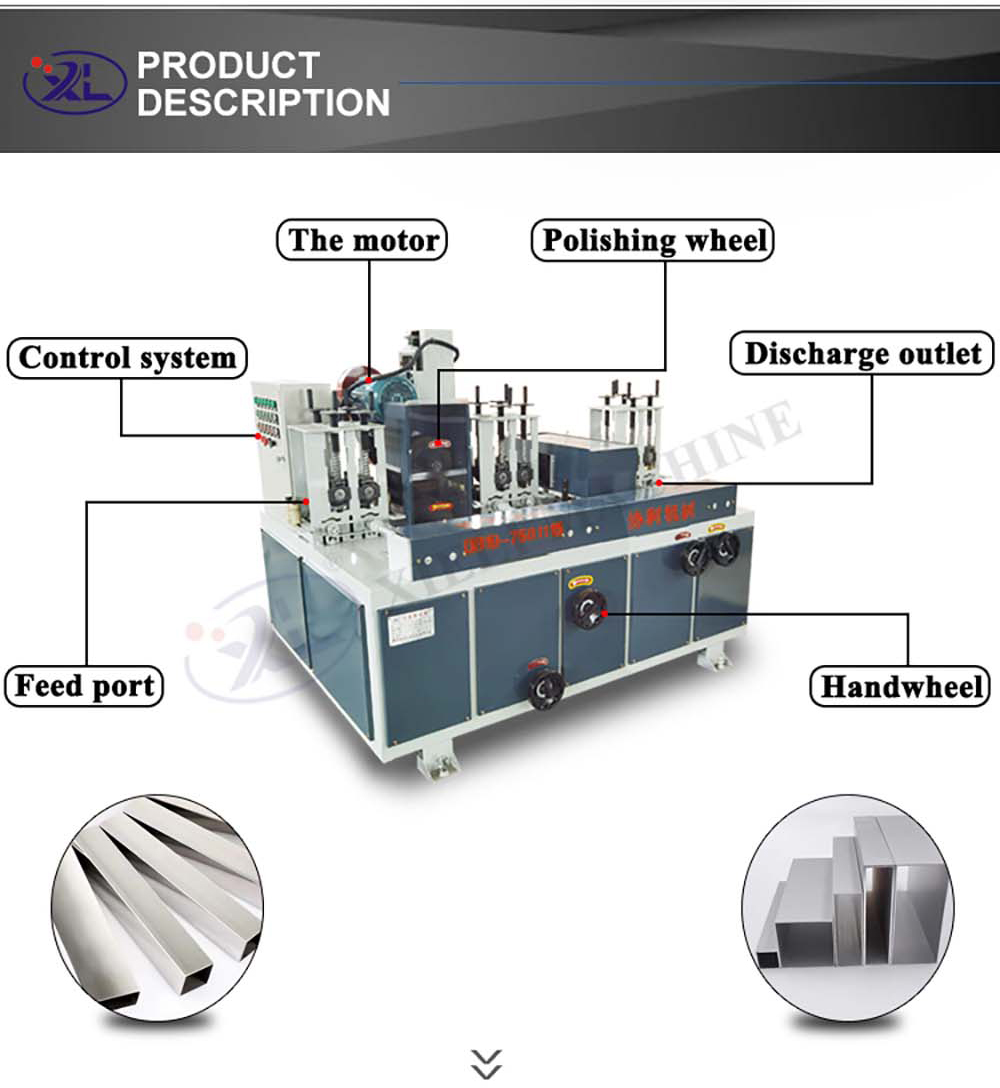

The primary components of these machines usually include polishing pads, abrasive materials, and a system to adjust the speed and pressure of the polishing process. Many modern machines are equipped with advanced technologies such as CNC (Computer Numerical Control) to enhance precision and consistency. This automation allows for repeatability in the finishing process, minimizing human error, and ensuring that each product meets stringent quality standards.

The Role of Metal Surface Polishing Machine Factories

Factories that specialize in the manufacturing of metal surface polishing machines play a critical role in this industry. They are responsible for designing and producing high-quality machines that cater to a wide array of metals including stainless steel, aluminum, brass, and more.

These factories not only focus on the production of polishing machines but often engage in extensive research and development (R&D) to innovate and improve existing technologies

. This commitment to R&D is crucial as it enables factories to respond to the evolving needs of their clients and the demands of various markets.Moreover, metal surface polishing machine factories also prioritize quality control. By implementing rigorous testing and quality assurance protocols, these factories ensure that every machine that leaves their production line is capable of delivering optimal performance. This meticulous attention to detail is what ultimately defines a reputable factory in this industry.

metal surface polishing machine factory

Environmental Considerations in Manufacturing

In today’s environmentally conscious world, metal surface polishing machine factories also face the challenge of adhering to sustainable practices. The production of these machines can have a significant impact on the environment, particularly when it comes to waste management and energy consumption.

Many factories are now adopting eco-friendly materials and methods to minimize their ecological footprint. This includes implementing energy-efficient manufacturing processes, reducing water usage, and recycling waste materials generated during production. By prioritizing sustainability, these factories are not only contributing to the protection of the environment but also appealing to a growing number of clients who prioritize green practices.

The Future of Metal Surface Polishing Machines

Looking ahead, the future of metal surface polishing machine factories appears promising. With advancements in technology, including automation and artificial intelligence, the capabilities of polishing machines are continuously improving. The integration of smart technology enables machines to analyze the polishing process in real-time, allowing for adjustments that enhance efficiency and output quality.

Additionally, as industries continue to evolve and new materials emerge, the demand for specialized polishing solutions will persist. Factories must remain agile and innovative to keep up with these changes, ensuring they can provide tailored solutions that meet the unique requirements of their clients.

Conclusion

Metal surface polishing machine factories are integral to achieving high-quality finishes in the manufacturing sector. Through their commitment to quality, innovation, and sustainability, these factories are positioned to meet the ever-growing demands of various industries. As technology continues to advance, the capabilities and efficiency of metal surface polishing machines will undoubtedly improve, paving the way for a future where perfection in finishing becomes increasingly attainable.