The Growing Demand for Metal Polishing and Buffing Machines A Look at Export Trends

In the global marketplace, the demand for metal polishing and buffing machines has witnessed significant growth over the past few years. As industries ranging from automotive to aerospace seek ways to enhance the finish and durability of their metal components, the role of these machines has become more critical than ever. This article delves into the factors driving the demand for metal polishing and buffing machines, the key exporters in this sector, and the future outlook for the industry.

Understanding Metal Polishing and Buffing

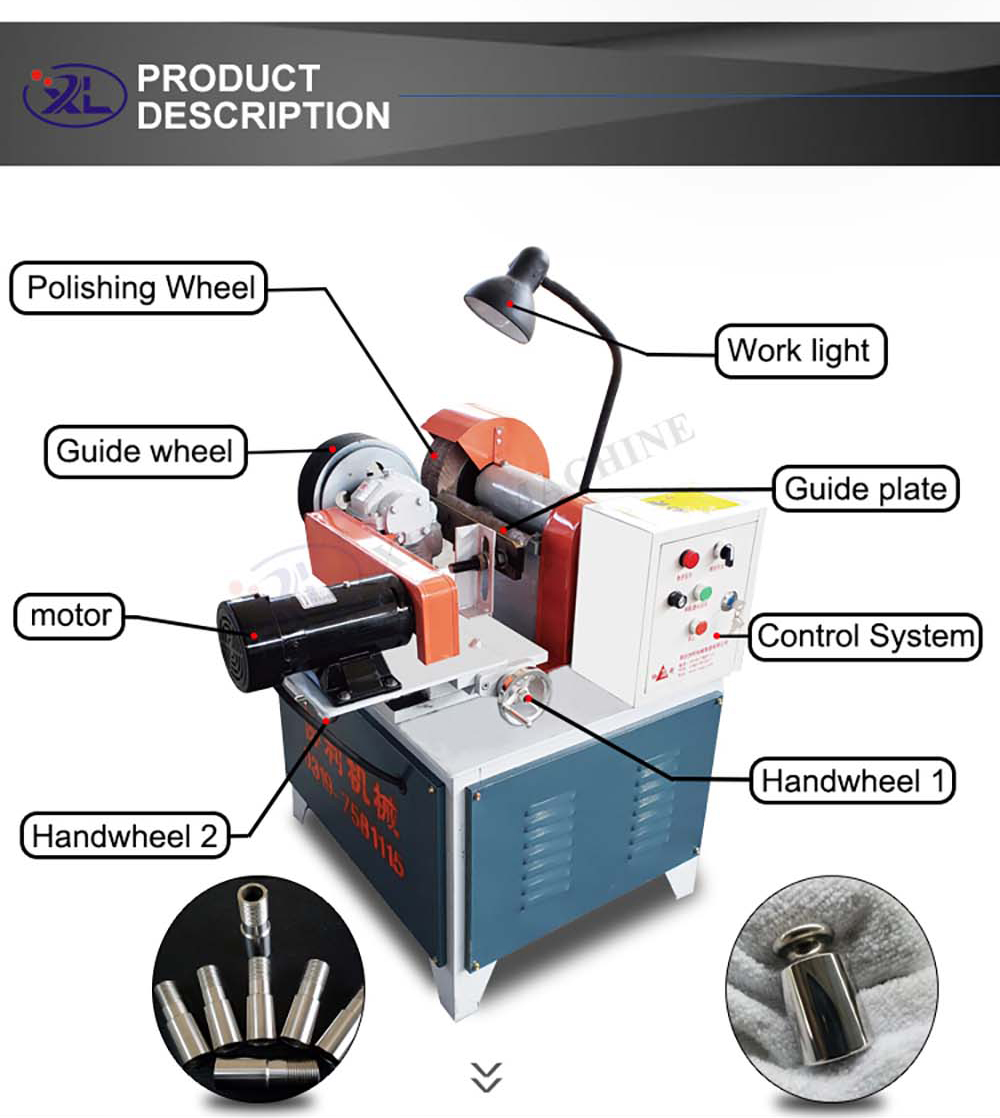

Metal polishing and buffing are processes designed to improve the appearance and smoothness of metal surfaces. Polishing is primarily designed to achieve a high-level finish, while buffing focuses on refining that finish to a shine. These processes are essential in many manufacturing and fabrication contexts, where the aesthetics and quality of metal products are paramount. Industries such as automotive manufacturing, jewelry production, and even kitchenware see significant applications for polished metals.

Key Factors Driving Demand

1. Industry Applications The automotive and aerospace industries are among the largest consumers of polished metals. Components such as engine parts, decorative trims, and structural elements often require superior finishing to withstand wear and corrosion. Meanwhile, consumer goods like cutlery and decorative items also benefit from enhanced aesthetics, thereby driving demand for polishing machines.

2. Advancements in Technology Recent innovations in polishing and buffing technology, including automated machines and CNC (computer numerical control) systems, have increased efficiency and reduced labor costs. These modern machines offer quicker processing times and consistent finishes, appealing to manufacturers striving for productivity and quality.

3. Sustainability Pressures With growing awareness around sustainability, manufacturers are looking for ways to minimize waste and energy consumption during the production process. Metal polishing machines that use less water and fewer chemicals have gained traction as industries shift towards greener practices.

4. Customization and Versatility The ability to customize polishing machines to suit different materials and products has become a competitive advantage. Exporters who offer a range of machines capable of handling diverse applications—from fine jewelry to heavy industrial components—are well-positioned in the global market.

metal polishing buffing machine exporters

Leading Exporters in the Market

Several countries have established themselves as key exporters of metal polishing and buffing machines. Nations like Germany, Italy, and the United States are known for their high-quality engineering and technology in this field. Moreover, emerging markets in Asia, particularly China and India, are beginning to challenge established players by offering cost-effective solutions without compromising quality.

German manufacturers, for example, are renowned for precision engineering and advanced technology. They dominate the high-end market with machines that provide exceptional performance and durability. Italian manufacturers, on the other hand, are well-known for their stylish designs and innovative features, appealing to luxury goods sectors.

In Asia, China's rapid industrial expansion has led to a surge in domestic manufacturing of polishing machines, allowing them to export competitively priced alternatives to the global market. India is also stepping up its presence, driven by a robust manufacturing sector and increasing investments in machine tools.

Future Outlook

The future of the metal polishing and buffing machine market appears bright. As technological advancements continue to reshape industries, demand for improved finishing techniques will likely increase. Furthermore, the push towards sustainable manufacturing processes will drive innovation in machine design, focusing on energy efficiency and waste reduction.

Additionally, as global trade barriers decrease and international partnerships grow, exporters will have more opportunities to enter new markets. Companies that can adapt to changing consumer preferences and invest in research and development will remain competitive.

In conclusion, the metal polishing and buffing machine industry is poised for continued growth, driven by technological advancements, expanding market applications, and a commitment to sustainability. For exporters operating in this space, understanding market trends and leveraging their strengths will be key to thriving in this dynamic environment.