The Evolution and Importance of Metal Pipe Polishing Machine Manufacturers

In the ever-evolving industrial landscape, the demand for precision and aesthetic quality in metal products has led to significant advancements in manufacturing technology. One of the crucial areas that has gained attention is the polishing of metal pipes. As industries ranging from construction to automotive increasingly rely on high-quality metal components, the role of metal pipe polishing machine manufacturers has become paramount.

Understanding Metal Pipe Polishing

Metal pipe polishing is a vital process in manufacturing that enhances both the functional and visual aspects of metal pipes. Polishing removes imperfections, scales, or oxidation from the surface of the pipes, resulting in a smoother finish. This not only improves corrosion resistance but also enhances the overall durability and lifespan of the product. Furthermore, a polished surface is often a requirement for aesthetic purposes, especially in industries where visual appearance is as important as performance.

The Role of Manufacturers

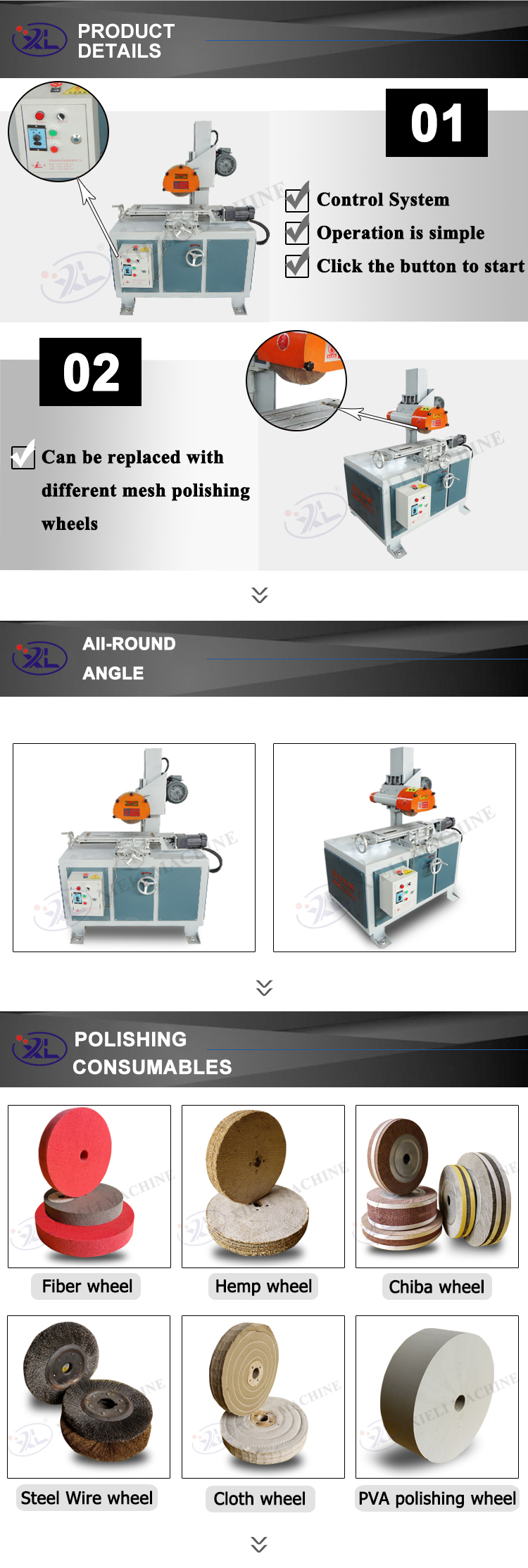

Manufacturers of metal pipe polishing machines are at the forefront of this essential process. They design and produce equipment that can efficiently polish a range of pipe sizes and materials, including stainless steel, aluminum, and carbon steel. These machines utilize various techniques such as mechanical polishing, brushing, and electropolishing to achieve desired surface finishes.

The continuous innovation in machine technology has led to the advent of advanced polishing solutions that are faster, more efficient, and environmentally friendly. For instance, manufacturers are now offering automated polishing systems, which not only reduce labor costs but also ensure consistent quality across batches. This automation is particularly significant in large-scale operations where time efficiency and precision are critical.

Key Features of Modern Polishing Machines

Modern metal pipe polishing machines come with several features that enhance their functionality. Some key aspects include

metal pipe polishing machine manufacturer

2. Versatility A good polishing machine can accommodate different pipe sizes and shapes, making it easier for manufacturers to handle varied production needs.

3. User-Friendly Interfaces With the shift towards automation, many machines now have intuitive controls and monitoring systems that help operators manage the polishing process more effectively.

4. Dust and Waste Management Advanced polishing machines are designed with systems that minimize dust and waste, promoting a cleaner work environment and adhering to environmental regulations.

The Future of Metal Pipe Polishing Machines

Looking ahead, the future of metal pipe polishing machines seems promising. With the growth of automation and smart manufacturing, further innovations are expected. The incorporation of Artificial Intelligence (AI) and Internet of Things (IoT) technologies could revolutionize the polishing process, allowing for predictive maintenance and real-time process optimization.

Moreover, as industries continue to emphasize sustainability, manufacturers will likely focus on creating machines that use less energy and produce fewer emissions while maintaining high performance levels.

Conclusion

In conclusion, metal pipe polishing machines are not just essential tools in the manufacturing process but also a reflection of the technological advancements in the industry. The role of metal pipe polishing machine manufacturers is crucial in meeting the rising demands for quality and performance. As these manufacturers innovate and adapt to new technologies, they play a key role in ensuring the metalworking industry's continued growth and evolution. The future undoubtedly holds exciting advancements that will further enhance the capabilities and efficiencies of metal pipe polishing, paving the way for even greater possibilities in industrial manufacturing.