Understanding the Pricing and Suppliers of Metal Polishing Machines

Metal polishing machines play a significant role in various industries, from automotive to aerospace, where the finishing touches determine the quality and aesthetics of the final product. As businesses look to enhance their production processes, understanding the pricing and suppliers of metal polishing machines becomes crucial.

The Importance of Metal Polishing Machines

Metal polishing is a critical mechanical process that improves the surface finish of metal parts, making them smoother, shinier, and more resistant to corrosion. This process not only enhances the visual appeal of products but also increases their durability, which is vital for industries where performance is paramount. The demand for metal polishing machines has surged as manufacturers seek efficient and reliable methods to achieve high-quality finishes.

Factors Influencing the Price of Metal Polishing Machines

Several factors influence the price of metal polishing machines. Understanding these can help businesses make informed purchasing decisions.

1. Type of Machine The market offers various types of metal polishing machines, including rotary polishers, belt polishers, and vibratory finishers. Each type serves different purposes and hence varies in price. For instance, rotary polishers may be less expensive but suitable only for specific applications, while vibratory finishers, which can handle larger loads, may come with a higher price tag.

2. Size and Capacity The size of the machine and its capacity to handle various metal parts also significantly impact pricing. Larger machines that can accommodate bigger and heavier components typically cost more.

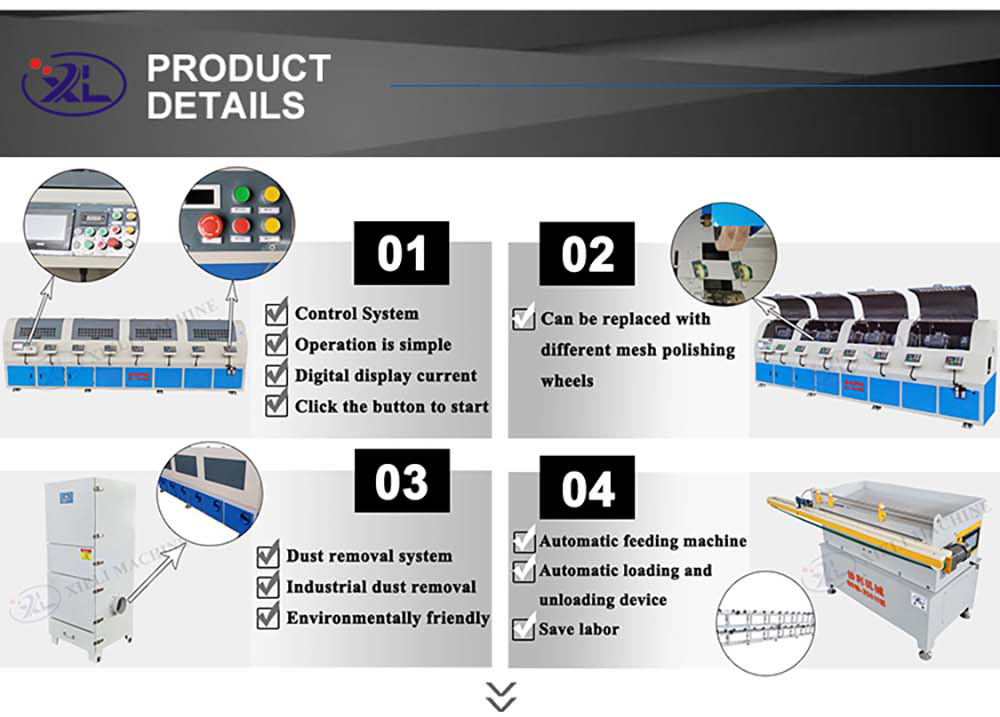

3. Material and Build Quality Machines constructed from durable materials designed to withstand wear and tear tend to be more expensive. Moreover, features such as automated polishing capability or advanced technology integration add to the cost.

4. Brand Reputation Established brands with a proven track record in the market may charge premium prices. Investing in machinery from a reputable supplier can be beneficial in terms of reliability and after-sales service.

metal polishing machine price supplier

5. Market Demand Supply chain issues or a sudden surge in demand can lead to price fluctuations. Keeping an eye on market trends helps businesses to time their purchases better.

Finding Reliable Suppliers

Finding a reputable supplier for metal polishing machines is as crucial as understanding their pricing. Here are some strategies to identify the right supplier

- Research Online Many suppliers have an online presence, making it easier to compare prices, features, and customer reviews.

- Trade Shows and Industry Exhibitions Attending industrial expos and trade shows can provide insights into the latest technology and allow direct interactions with suppliers.

- Networking Industry contacts can offer recommendations based on firsthand experiences, helping you identify trustworthy suppliers.

- Ask for Demonstrations Before making a purchase, asking for a demonstration can provide clarity on the machine’s capabilities and efficiency.

- After-sales Support Choose suppliers that offer comprehensive warranties and after-sales support. This can be crucial for resolving any issues that may arise post-purchase.

Conclusion

Investing in a metal polishing machine is a significant decision that can enhance production quality and efficiency. By understanding the factors influencing pricing and identifying reliable suppliers, businesses can make informed purchases that align with their operational needs. Ultimately, the right machine from the right supplier can lead to superior finishes and increased customer satisfaction, driving business success in competitive industries.