The Importance of Metal Pipe Polishing Machines

In today's manufacturing industry, the finishing process plays a crucial role in ensuring the quality and appeal of metal products. Among the various finishing techniques, metal pipe polishing has gained significant importance, particularly for industries that require high standards of aesthetics and functionality. One of the essential tools in this process is the metal pipe polishing machine. This article will explore the significance of these machines, their types, and their benefits to manufacturers.

Metal pipe polishing machines are designed specifically to enhance the surface finish of metal pipes, which are used across a wide range of industries, including automotive, aerospace, construction, and plumbing. The polishing process helps remove surface imperfections, scratches, and oxidation, resulting in a smooth and shiny finish. This not only improves the visual appeal of the pipes but also enhances their resistance to corrosion and wear, which is vital for their longevity and performance.

There are several types of metal pipe polishing machines available, each catering to different requirements and specifications. One common type is the belt polishing machine, which utilizes an abrasive belt to polish the surface of the pipe. This machine is ideal for both straight and curved pipes and is known for its efficiency and versatility. Other types include tube polishing machines, which are specifically designed for tubular products, and portable polishing machines, which are suitable for on-site polishing applications.

The benefits of using metal pipe polishing machines are manifold. Firstly, they significantly reduce the time and labor required to achieve a high-quality finish. Manual polishing can be labor-intensive and time-consuming, often resulting in inconsistent quality. In contrast, modern polishing machines are equipped with advanced technology that allows for a uniform finish across many pipes in a fraction of the time it would take manually.

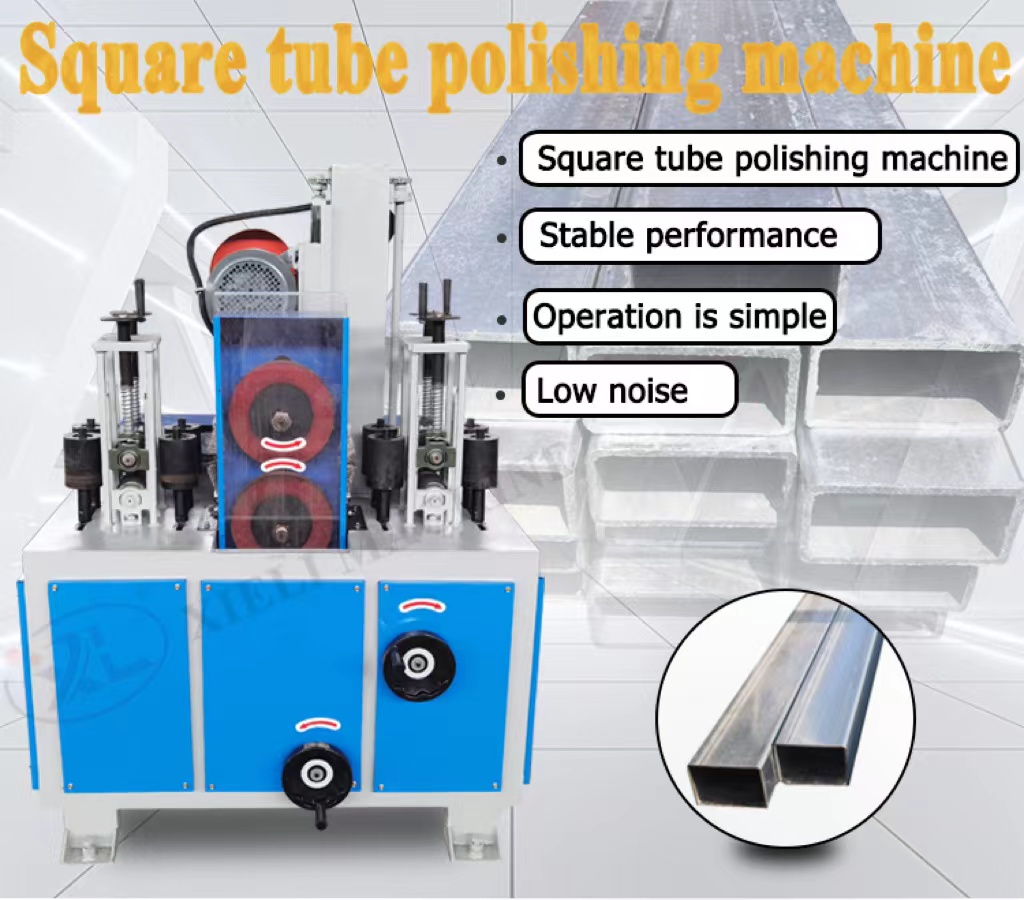

metal pipe polishing machine

Moreover, these machines enhance workplace safety. Manual polishing can involve exposure to harmful dust and particles. Automated polishing machines help reduce this risk by containing the process within a controlled environment, thereby improving the safety of workers.

Another advantage is the precision that these machines offer. Many modern metal pipe polishing machines come with adjustable settings that allow operators to fine-tune the polishing process according to the type of metal and the desired finish. This precision ensures that manufacturers can meet the specific requirements of their customers, leading to higher satisfaction and repeat business.

In addition to improving the quality and safety of the polishing process, investing in metal pipe polishing machines can result in significant cost savings for manufacturers. By automating the polishing process, companies can reduce labor costs and improve throughput, allowing for quicker turnaround times on projects. The durability and efficiency of these machines also mean that they require less maintenance over time, reducing long-term operating costs.

In conclusion, metal pipe polishing machines play an indispensable role in the manufacturing sector. They not only enhance the aesthetic appeal and durability of metal pipes but also improve efficiency and safety in the workplace. With the increasing demand for high-quality metal products across various industries, investing in a reliable metal pipe polishing machine is essential for manufacturers striving to maintain a competitive edge. As technology continues to evolve, we can expect even more sophisticated machines that will further enhance the metal finishing process, making it faster, safer, and more efficient than ever before.