Square Tube Grinding Machine Manufacturers Revolutionizing Metal Processing

In the realm of metal processing and manufacturing, the significance of precision and efficiency cannot be overstated. One vital piece of machinery that has gained prominence in recent years is the square tube grinding machine. This essential equipment is designed to enhance the quality of square tubes by providing a smooth, uniform finish and ensuring precise dimensions. With the increasing demand for high-quality metal components across various industries, the role of square tube grinding machine manufacturers has become more crucial than ever.

Understanding Square Tube Grinding Machines

Square tube grinding machines are specialized tools that utilize various methods to grind and polish square tubes, typically made from steel, aluminum, or other metals. These machines function by removing imperfections and surface irregularities, which ultimately results in a superior finish. The grinding process can significantly improve the aesthetic appeal of the tubes and enhance their resistance to wear and corrosion.

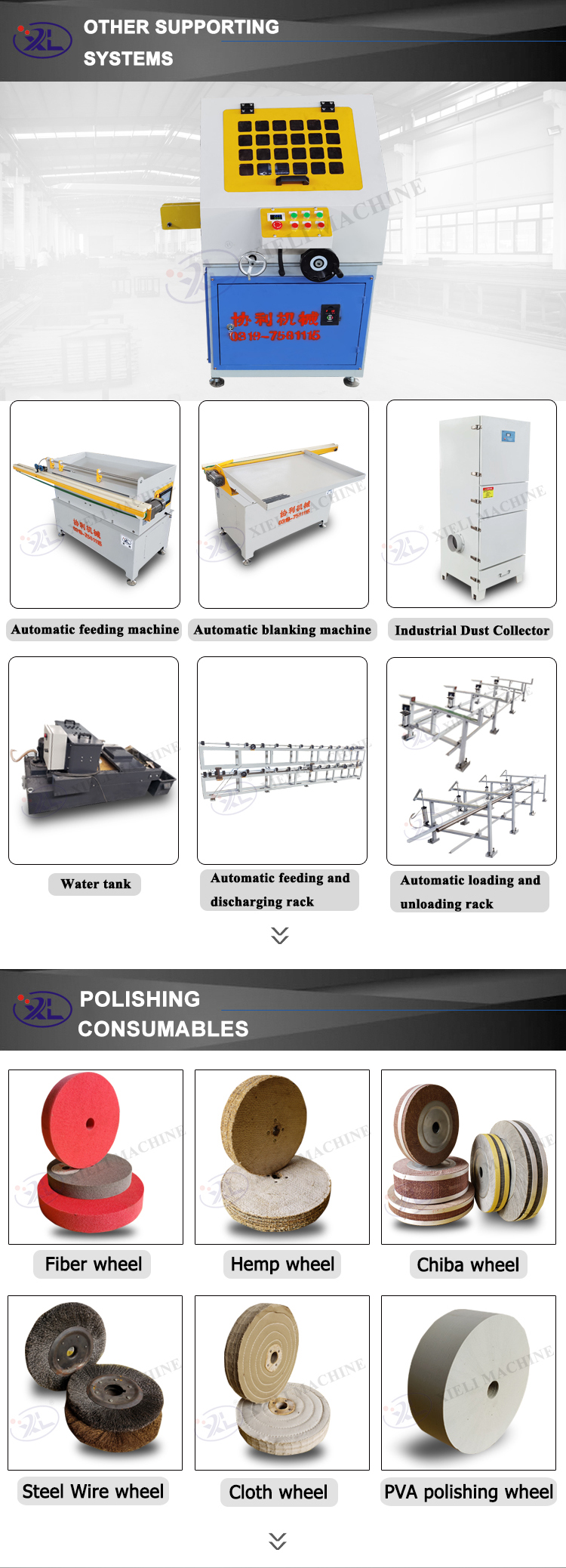

Manufacturers of square tube grinding machines focus on producing equipment equipped with advanced features such as automated feeding systems, multi-axis capabilities, and programmable logic controllers (PLCs) for precision control. This innovation not only boosts productivity but also ensures consistency in quality, which is essential for meeting stringent industry standards.

The Importance of Choosing the Right Manufacturer

Selecting the right manufacturer for square tube grinding machines is integral to the success of any manufacturing operation. With a plethora of options available, businesses must consider several factors to make an informed decision. Key aspects include

1. Quality and Reliability A reputable manufacturer will provide machines built to withstand the demands of continuous operation. High-quality materials and meticulous engineering are hallmarks of reliable machinery.

2. Technical Support and Customer Service The ongoing support from manufacturers can prove invaluable. From installation assistance to troubleshooting and maintenance, strong technical support can help minimize downtime and maximize productivity.

square tube grinding machine manufacturer

3. Customization Options Every manufacturing process is unique, and the need for customized solutions has never been greater. A good manufacturer should be able to work closely with clients to tailor their equipment to specific needs, whether that involves adjustments to the grinding process or modifications to accommodate different tube sizes.

4. Innovation and Technology The industry is continually evolving, and staying ahead of the curve is crucial. Manufacturers that invest in research and development tend to offer cutting-edge solutions that can improve efficiency and effectiveness in grinding operations.

5. Cost-Effectiveness While price shouldn’t be the sole deciding factor, it is essential to consider the overall value offered by a manufacturer. Balancing cost with quality and support services can drive better long-term success.

Future Prospects

The future of square tube grinding machines looks promising, driven by advancements in technology and increased demand in various sectors such as construction, automotive, and aerospace. As industries become more automated and integrate Industry 4.0 principles, we can expect square tube grinding machine manufacturers to innovate continuously, incorporating smart technologies like IoT (Internet of Things) devices for real-time monitoring and analytics.

Moreover, the environmental impact of manufacturing processes is gaining attention. Sustainable practices and energy-efficient machines will likely become a standard, with manufacturers focusing on reducing waste and minimizing environmental footprints.

Conclusion

In conclusion, square tube grinding machine manufacturers play a pivotal role in enhancing the capabilities of metal processing industries. By offering innovative, reliable, and customizable solutions, these manufacturers are not only improving the efficiency of manufacturing operations but also contributing to the overall quality of metal products. As the industry progresses, collaboration and adaptability will ensure that manufacturers continue to meet the evolving demands of their customers while driving innovation in metal processing technologies.