The Rise of Pipe Polishing Machine Manufacturers Meeting the Needs of Modern Industries

In today’s industrial landscape, the demand for high-quality pipe processing has seen a remarkable increase. As industries strive for excellence, the significance of pipe polishing cannot be overstated. This is where pipe polishing machine manufacturers come into play, crafting essential equipment that enhances the aesthetic appeal and functionality of metal pipes used in various applications.

Pipe polishing machines are vital in sectors such as construction, automotive, aerospace, and manufacturing. Metal pipes, once treated and polished, exhibit greater resistance to corrosion, improved adhesion for coatings, and an overall enhanced appearance. These machines utilize advanced technologies to ensure that pipes reach the highest standards of smoothness and shine, which are crucial for both aesthetic and performance-related reasons.

Manufacturers of pipe polishing machines are continually innovating to meet the evolving needs of their clients. These companies provide a range of machines, including automatic and semi-automatic polishing units, that can cater to different types of pipes and materials, such as stainless steel, aluminum, and copper. The versatility of these machines is essential in a market that demands customization and efficiency.

One of the primary advantages of modern pipe polishing machines is their ability to automate processes that were previously time-consuming and labor-intensive. By implementing automation, manufacturers have significantly reduced lead times, minimizing the human error factor and enhancing the uniformity of the polished finish. This increases throughput while allowing operators to focus on other critical aspects of production.

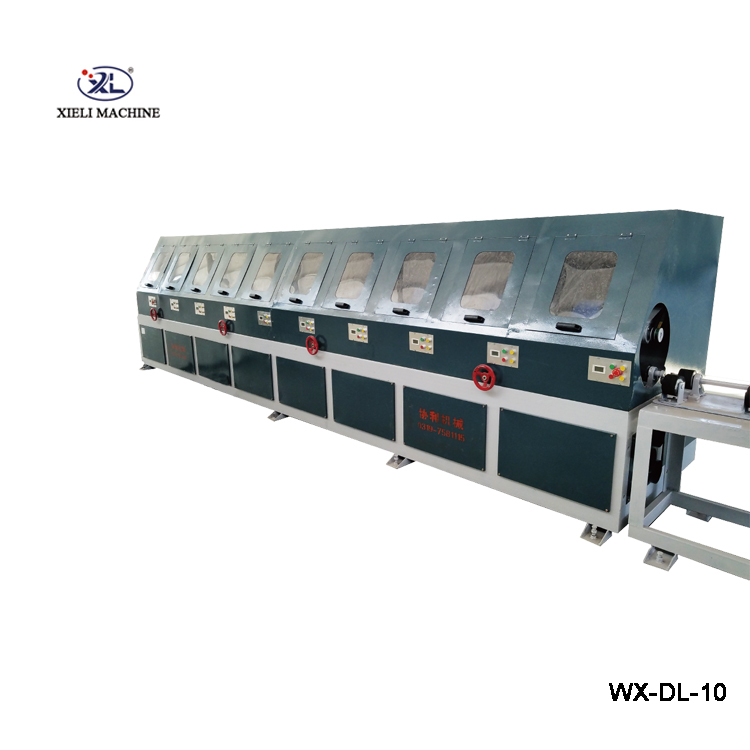

pipe polishing machine manufacturers company

Another notable trend is the growing emphasis on sustainability within the manufacturing sector. Pipe polishing machine manufacturers are now integrating eco-friendly practices into their production processes. This includes utilizing energy-efficient components, recyclable materials, and technologies that minimize waste. As industries become more conscious of their environmental footprint, the demand for such machines has surged, reflecting a wider push towards sustainable manufacturing.

Moreover, the globalization of industries has resulted in a need for pipe polishing machines that adhere to various international standards. Manufacturers must stay updated with these regulations to ensure compliance and competitiveness in the global market. This ongoing commitment to quality and adherence to standards fosters trust and loyalty among clients, which is vital for long-term business success.

Partnerships and collaborations across borders have also become common among pipe polishing machine manufacturers. These alliances enable companies to share technology, resources, and expertise, leading to the development of superior machines tailored to meet diverse market demands. Through such collaborations, manufacturers can introduce cutting-edge innovations that push the boundaries of what these machines can achieve.

To conclude, the role of pipe polishing machine manufacturers is crucial in meeting the high standards expected by modern industries. Their commitment to innovation, automation, and sustainability ensures that they are well-positioned to cater to the growing demands of the market. As industries continue to evolve, these manufacturers will play a pivotal role in shaping the future of pipe processing, contributing to enhanced product quality and operational efficiency across various applications. The future is bright for pipe polishing machine manufacturers, as they adapt and thrive in an ever-changing industrial landscape, solidifying their place as key players in the manufacturing process.