CNC Centerless Grinder Factory Manufacturers Precision and Innovation in Grinding Technology

In the ever-evolving world of manufacturing, precision engineering plays a crucial role in ensuring product quality and operational efficiency. One of the key players in this realm is the CNC centerless grinder, a specialized machine tool designed for the grinding of cylindrical components without the need for a center setup. As the demand for high-quality machined parts continues to grow, CNC centerless grinder factory manufacturers are at the forefront of innovation and technological advancement.

Understanding CNC Centerless Grinding

CNC (Computer Numerical Control) centerless grinding is a method that involves the grinding of cylindrical workpieces in a setup that does not require the use of centers. This technique is particularly advantageous for mass production processes, as it allows for continuous feeding of workpieces and high levels of automation. The centerless grinding process consists of three main components the grinding wheel, the regulating wheel, and the workpiece itself. The interaction between these elements permits accurate and efficient material removal.

CNC centerless grinders are known for their precision and versatility, capable of handling a range of materials, including metals, plastics, and composites

. They can be used to achieve tight tolerances and smooth finishes, making them ideal for industries such as automotive, aerospace, electronics, and medical devices.The Role of Manufacturers

CNC centerless grinder factory manufacturers play a pivotal role in the production of these sophisticated machines. Their expertise lies in designing, engineering, and building grinders that meet specific industry requirements. These manufacturers invest heavily in research and development to incorporate the latest technological advancements into their products. This includes automating processes, enhancing grinding accuracy, and improving user interfaces with advanced CNC control systems.

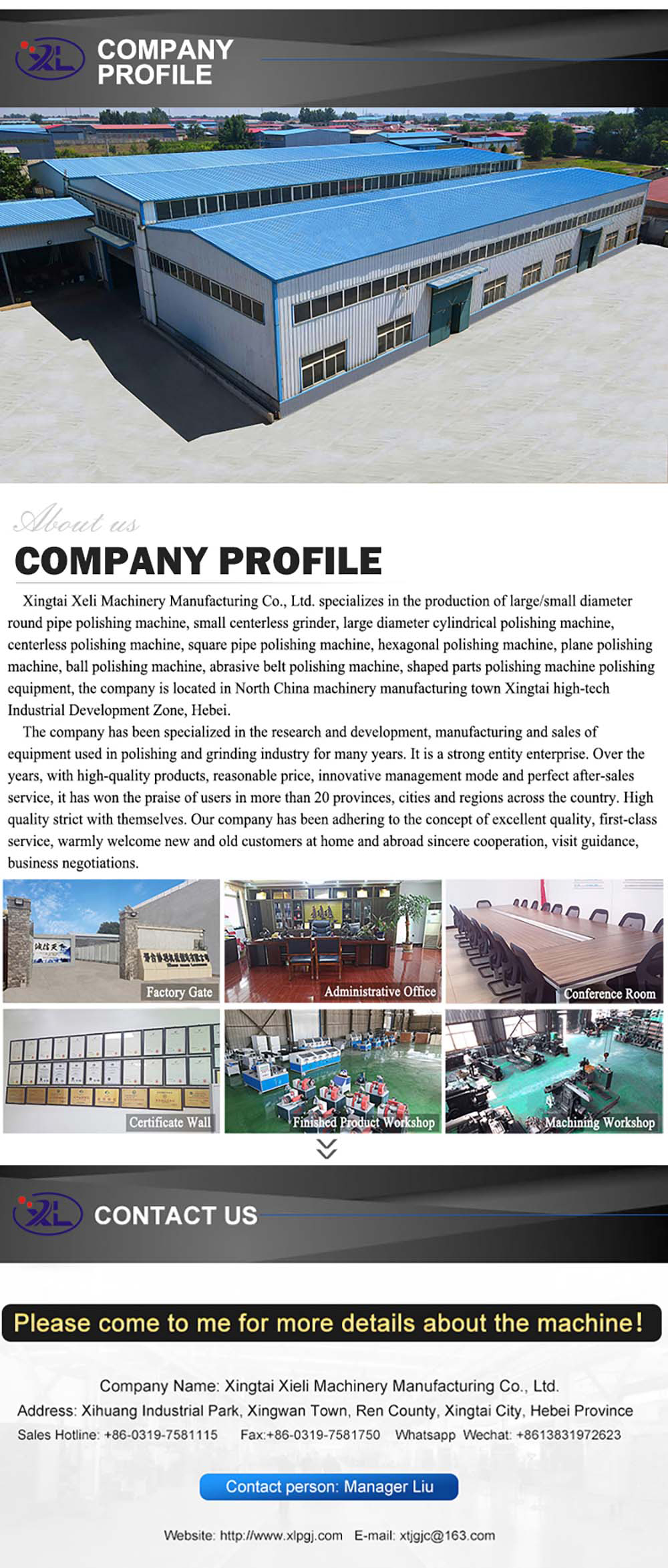

cnc centerless grinder factory manufacturer

Heavy emphasis is also placed on quality control throughout the manufacturing process. Each machine undergoes rigorous testing to ensure it meets stringent industry standards. By maintaining high-quality production standards, manufacturers provide customers with reliable machines that can withstand the demands of continuous operation.

Innovation in Technology

Today’s CNC centerless grinders are equipped with cutting-edge technology that enhances their performance and efficiency. For instance, many manufacturers are integrating IoT (Internet of Things) features, enabling machines to communicate data such as operating metrics, maintenance schedules, and performance statistics. This connectivity allows manufacturers to monitor productivity in real-time and make data-driven decisions to optimize operations.

Moreover, advancements in software have made programming CNC machines more intuitive. User-friendly interfaces allow operators to set up grinding parameters quickly, leading to reduced downtime and increased output. Enhanced simulation capabilities also enable manufacturers to visualize the grinding process before actual production, minimizing errors and improving workflow.

Conclusion

CNC centerless grinder factory manufacturers are essential contributors to the precision machining landscape. With their commitment to innovation, quality, and reliability, they empower industries to achieve high standards of production. As technological advancements continue to shape the manufacturing sector, these manufacturers are poised to lead the way, ensuring that CNC centerless grinding remains a cornerstone of efficient and precise machining processes. The future of grinding technology looks promising, driven by the ingenuity of these manufacturers who are dedicated to excellence in every aspect of their craft.