Metal Tube Polishing Machine Manufacturers Driving Quality and Efficiency in Metal Fabrication

In today's rapidly evolving manufacturing landscape, the demand for high-quality metal products continues to grow. At the core of this demand lies the need for precision in metal fabrication processes, particularly in finishing techniques like polishing. Metal tube polishing machines play a crucial role in this process, ensuring that metal tubes deliver not only aesthetic appeal but also enhanced performance properties. This article explores the significance of metal tube polishing machine manufacturers and their impact on the metalworking industry.

Metal tube polishing is a specialized process that enhances the surface finish of metal tubes. By removing imperfections such as scratches, oxidation, and other contaminants, polishing not only improves appearance but also contributes to the overall performance of the product. For industries such as automotive, aerospace, and construction, where precision and reliability are paramount, a superior surface finish can reduce friction, enhance corrosion resistance, and increase the lifespan of components.

Manufacturers of metal tube polishing machines employ advanced technology to cater to the diverse needs of various industries. These machines come in various forms, including belt polishers, rotary polishers, and abrasive finishing systems, each designed to tackle specific polishing challenges. Companies focus on creating machines that are not only efficient but also user-friendly, allowing operators to achieve consistent quality with minimal effort.

One of the key trends in the metal tube polishing machine manufacturing sector is the integration of automation and smart technologies. Manufacturers are increasingly adopting robotic systems and computer numerical control (CNC) features to enhance precision and reduce human error. These advanced systems can handle multiple polishing tasks autonomously, significantly increasing throughput while ensuring uniformity across production runs. As a result, businesses can achieve greater efficiency and cost-effectiveness, ultimately improving their competitive edge in the market.

metal tube polishing machine manufacturer

Sustainability is another critical consideration for modern manufacturers. With increasing awareness of environmental issues, metal tube polishing machine manufacturers are developing eco-friendly solutions that minimize waste and reduce energy consumption. By utilizing non-toxic polishing compounds and implementing closed-loop systems that recirculate water and other resources, these manufacturers are contributing to a greener manufacturing environment.

Moreover, the flexibility of modern metal tube polishing machines has opened up new avenues for customization. Manufacturers now offer tailored solutions that cater to specific industry standards and client requirements. Whether it’s processing unique alloy compositions or meeting stringent dimensional specifications, these specialized machines ensure that end-users receive products that perfectly match their needs.

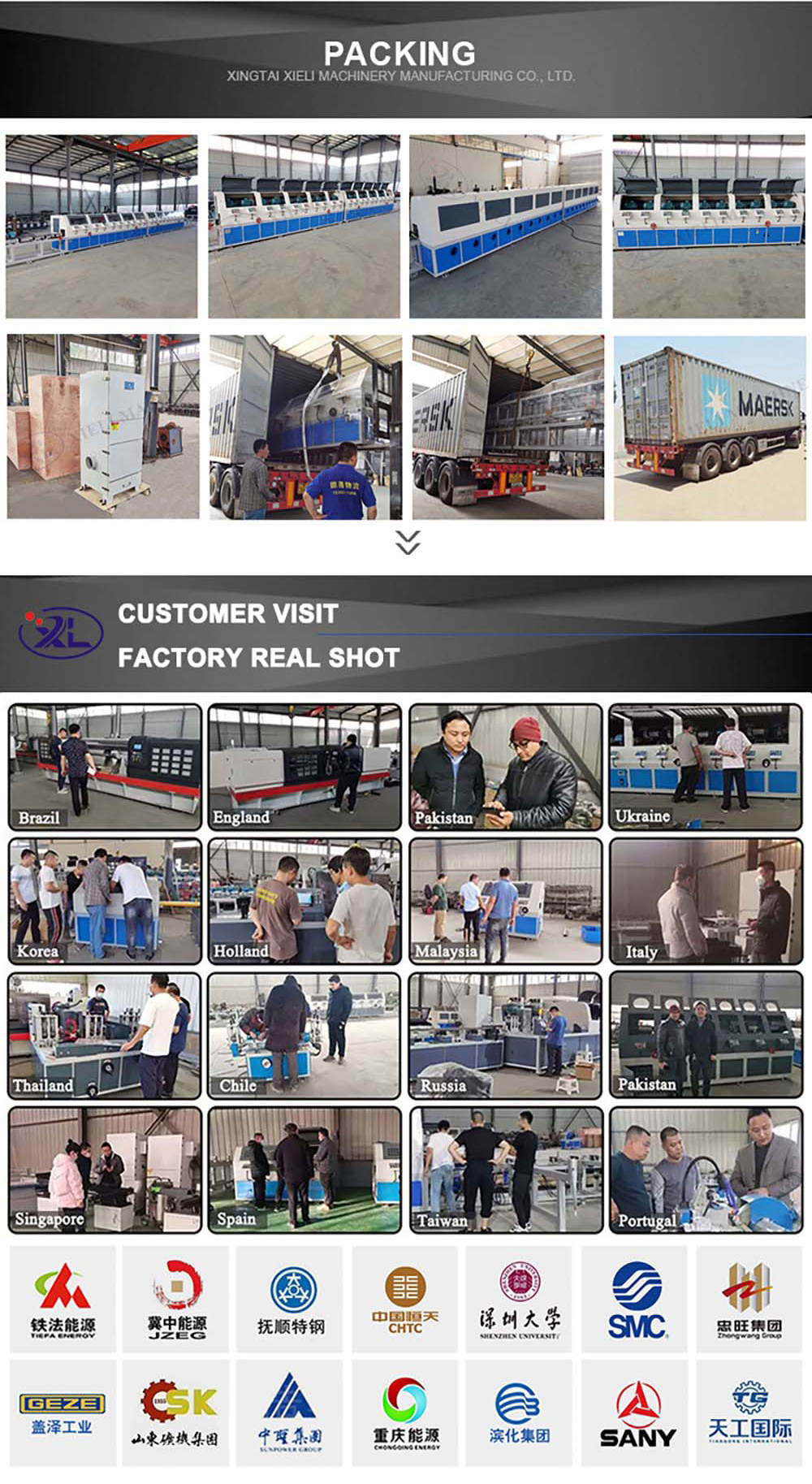

In addition to manufacturing, support and service play pivotal roles in the longevity and effectiveness of metal tube polishing machines. Leading manufacturers provide comprehensive training, maintenance, and technical support to help clients maximize the productivity of their equipment. This commitment to customer service fosters long-term relationships and establishes trust, which is vital in an industry that relies heavily on equipment uptime and reliability.

Overall, metal tube polishing machine manufacturers are at the forefront of enhancing quality and efficiency in metal production. Their innovative solutions not only meet the demands of the market but also push the boundaries of what is possible in metal fabrication. As industries evolve and embrace new challenges, these manufacturers will continue to play a crucial role in shaping the future of metalworking, driving both technological advancements and sustainability initiatives. In a world where precision and quality are paramount, investing in advanced polishing solutions is not just a necessity but a strategic advantage for businesses aiming to excel in a competitive marketplace.