The Junker Centerless Grinder Revolutionizing Precision Machining

In the realm of advanced manufacturing, precision and efficiency are paramount. One machine that has significantly impacted the precision machining industry is the Junker Centerless Grinder. This innovative piece of equipment has become a staple for manufacturers looking to optimize their grinding processes, making it a cornerstone in various industries, including automotive, aerospace, and medical.

Understanding Centerless Grinding

Centerless grinding is a form of grinding where the workpiece is positioned between two grinding wheels, one of which is stationary (the grinding wheel) and the other is rotating (the regulating wheel). The workpiece is held in place by the force of the grinding wheel and is guided through the machine via the regulating wheel. This design allows for continuous grinding without needing to reposition the workpiece, leading to enhanced production rates and improved precision.

The Junker Centerless Grinder takes this principle to the next level

. With a robust design and advanced technology, it delivers exceptional performance and quality that can meet the highest industry standards.Key Features of Junker Centerless Grinders

One of the standout features of Junker Centerless Grinders is their automated systems. These machines come equipped with sophisticated control technologies that allow for real-time monitoring and adjustments. This means that operators can oversee multiple machines simultaneously, ensuring that each is running optimally while maintaining quality and consistency across production batches.

Another notable aspect is the grinder's versatility. The Junker models can handle a wide range of materials, including hardened steels, aluminum, and even plastic composites. This adaptability makes them suitable for a variety of applications, from cutting tools to intricate automotive components.

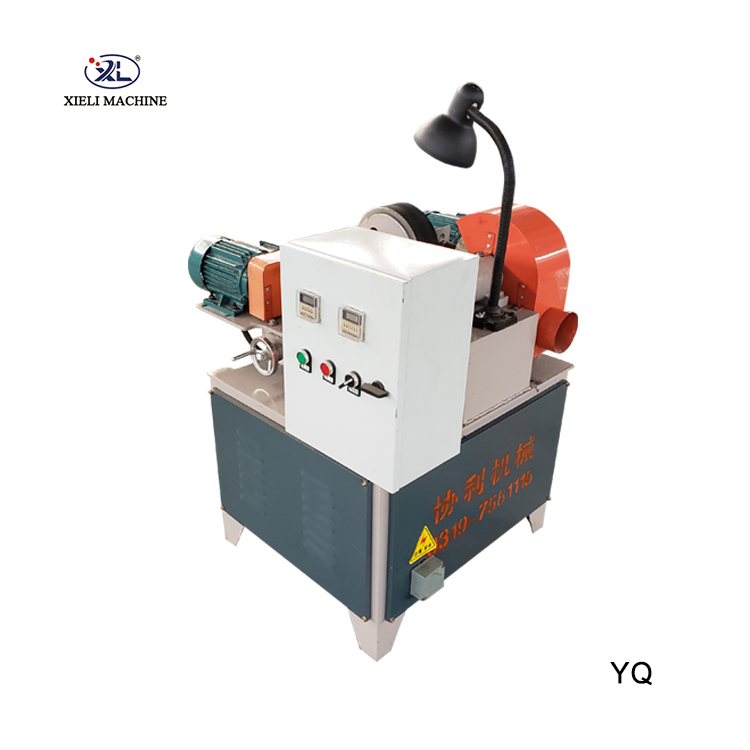

junker centerless grinder

Moreover, the efficiency of Junker Centerless Grinders is evident in their rapid setup times and minimal downtime for maintenance. The user-friendly interface allows operators to quickly change settings, switch between different grinding methods, and fine-tune parameters to achieve desired specifications. This agility is crucial in today’s fast-paced manufacturing environments, where time is money.

Applications Across Industries

The applications for Junker Centerless Grinders are vast. In the automotive sector, they are employed for grinding camshafts, crankshafts, and various other precision components that require stringent tolerances. The aerospace industry benefits similarly, where the need for lightweight, durable parts is paramount and the slightest deviation can have serious implications.

In the medical field, the precision capabilities of the Junker grinder are utilized for producing surgical instruments and implants that demand high levels of consistency and quality. The ability to process different materials and maintain tight tolerances is crucial in ensuring the reliability and safety of medical devices.

The Future of Grinding Technology

As industries continue to push the boundaries of innovation, so too does the technology behind grinding machines. Junker is at the forefront of these advancements, investing in research and development to further enhance the capabilities of their centerless grinders. The incorporation of artificial intelligence and machine learning is on the horizon, promising to make grinding processes even more efficient and foolproof.

As the manufacturing landscape evolves, the need for precision and efficiency will remain a driving force. Junker Centerless Grinders, with their cutting-edge technology and versatility, are well-positioned to meet these demands. They not only optimize grinding processes but also contribute to the overall improvement of production output and quality, solidifying their place as an essential tool in modern manufacturing.

In conclusion, the Junker Centerless Grinder represents a significant leap forward in the field of precision machining. By combining advanced technology with robust design and adaptability, Junker has created a machine that meets the diverse needs of various industries. As we look to the future, one thing is clear the importance of precision in manufacturing will only continue to grow, and the Junker Centerless Grinder will undoubtedly play a key role in that evolution.