The Precision of Jainnher Centerless Grinding Machines

In the realm of manufacturing, precision is not just a goal; it's a necessity. Jainnher, a renowned name in the field of centerless grinding machines, has carved a niche by delivering high-precision machinery that meets the diverse needs of industries such as automotive, aerospace, and electronics. This article explores the significance of centerless grinding, the features of Jainnher machines, and how they contribute to enhanced manufacturing processes.

Understanding Centerless Grinding

Centerless grinding is a machining process where the workpiece is held in place by two wheels the grinding wheel and the regulating wheel. This method allows for continuous grinding of workpieces without requiring a central fixture. The absence of a fixed center point leads to remarkable efficiency, making it an ideal choice for mass production.

One of the primary advantages of centerless grinding is its ability to produce cylindrical components with high precision and uniformity. This process is favored when dealing with large quantities of small to medium-sized parts, such as rods, bars, and tubes. The streamlined nature of centerless grinding translates to reduced cycle times and increased productivity, essential factors in today’s competitive manufacturing landscape.

The Jainnher Advantage

Jainnher’s centerless grinding machines are celebrated for their advanced technology, versatility, and user-friendly operation. With a focus on innovation, Jainnher has developed a range of machines that cater to various grinding needs, ensuring customers get not just a product but a comprehensive solution for their grinding challenges.

1. High Precision Jainnher machines are designed with precision engineering in mind. This allows for exceptionally tight tolerances and superior surface finishes, which are crucial for industries where even the slightest deviation can lead to significant operational issues.

2. Versatile Configurations Understanding that each industry has unique requirements, Jainnher offers customizable machines that can accommodate different sizes and shapes of workpieces. This flexibility makes it easier for manufacturers to adapt to changing product lines without significant downtime.

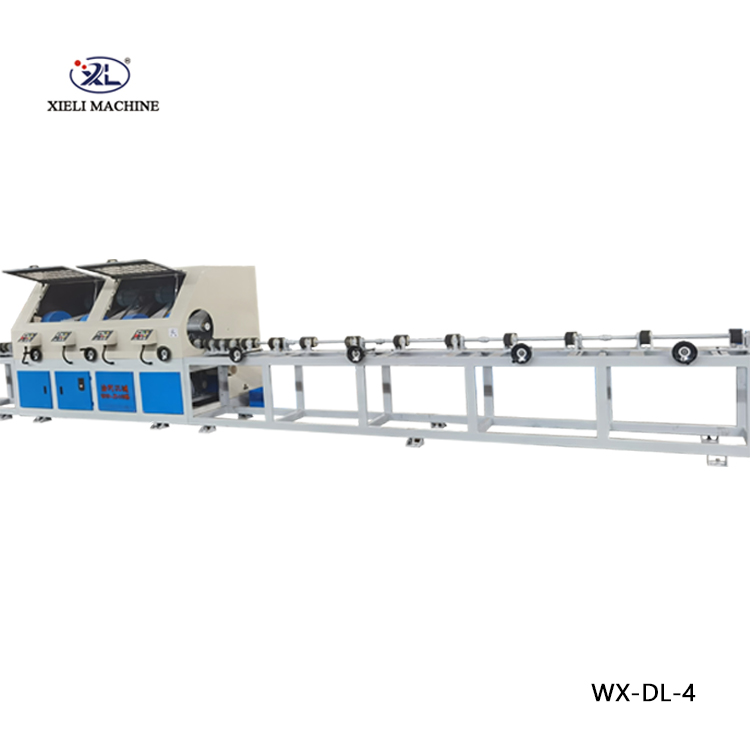

jainnher centerless grinding machine products

3. User-Friendly Interface The intuitive controls on Jainnher machines ensure that operators can easily set up and adjust the machines for optimal performance. This minimizes training time and enhances operational efficiency, allowing businesses to maximize their productivity.

4. Robust Build Quality Jainnher machines are built to last, using high-quality materials and components that withstand rigorous manufacturing processes. This durability translates to lower maintenance costs and longer machine life, making them a worthwhile investment.

5. Advanced Technology Incorporating state-of-the-art technology such as CNC control and in-process measurement systems, Jainnher machines enhance precision and consistency. Features such as automated adjustments help maintain optimal grinding conditions, reducing the chances of human error.

Applications in Various Industries

Jainnher’s centerless grinding machines find applications across a multitude of industries. In the automotive sector, they are instrumental in producing various components such as shafts, bearings, and valves, ensuring that these critical parts meet stringent quality standards. In the aerospace industry, where safety and reliability are paramount, Jainnher machines help manufacture precise components that contribute to the overall performance of aircraft.

Moreover, the electronics industry benefits from the micro-grinding capabilities of Jainnher machines, enabling the production of intricate parts for devices such as smartphones and medical equipment. This ability to accommodate a wide range of materials—from metals to plastics—further highlights the versatility of Jainnher’s offerings.

Conclusion

As manufacturing continues to evolve, the demand for precision, efficiency, and reliability in machining processes remains steadfast. Jainnher stands out in this landscape with its high-performance centerless grinding machines that not only meet but exceed industry expectations. By investing in Jainnher technology, manufacturers can ensure they remain competitive, delivering high-quality products that meet the rigorous demands of modern industry.

In summary, Jainnher’s commitment to innovation and quality makes it a trusted partner for businesses seeking to optimize their grinding processes, ensuring they can produce exceptional components with unparalleled precision. With Jainnher, the future of grinding is not just about performing a function; it's about setting new standards of excellence.