Tube Polishing Machines in India A Comprehensive Overview

In the realm of industrial manufacturing, tube polishing machines play a crucial role in enhancing the aesthetic and functional qualities of metal tubes and pipes. India, with its rapidly growing manufacturing sector, has become a hotspot for the production and distribution of these machines. This article delves into the importance of tube polishing machines, the various types available in India, and the factors driving their popularity.

The Importance of Tube Polishing

Tube polishing is an essential process in numerous industries, including automotive, aerospace, food and beverage, pharmaceuticals, and construction. Polishing serves not only to improve the visual appeal of metal tubes but also to remove impurities and enhance corrosion resistance. This is particularly critical for stainless steel tubes, which are widely used in environments where hygiene and cleanliness are paramount.

A well-polished tube has a smoother surface, reducing friction and enhancing its overall performance. The process also helps in preparing the surface for further treatments, such as coating or plating. As manufacturers strive for high-quality products, investing in efficient tube polishing machines has become indispensable.

Types of Tube Polishing Machines

In India, the market offers a diverse range of tube polishing machines catering to various needs. Some of the most common types include

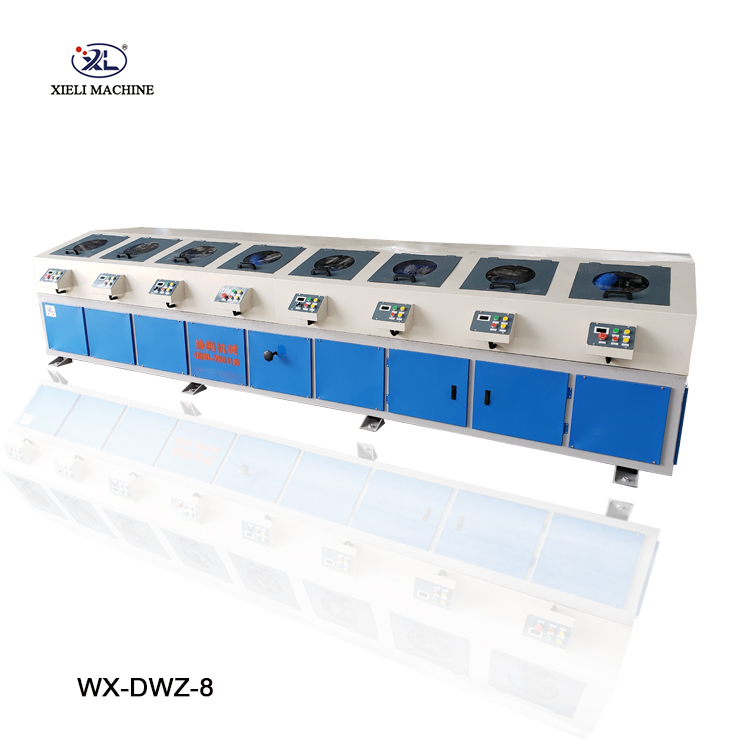

1. Automatic Tube Polishing Machines These machines are designed for high-volume production, capable of polishing multiple tubes simultaneously. They are user-friendly, often equipped with programmable controls that allow for easy adjustments and enhanced precision.

2. Semi-Automatic Machines Striking a balance between manual and automated processes, semi-automatic machines require some level of operator intervention. They are suitable for medium-scale operations and can be easily adapted for different polishing tasks.

3. Manual Tube Polishing Machines Although more labor-intensive, manual polishing machines offer the advantage of flexibility and control. They are generally less expensive and are favored by small-scale manufacturers or workshops needing versatile solutions.

tube polishing machine india products

4. Specialized Polishing Systems Some manufacturers provide customized solutions tailored for specific industries or types of tubes. These specialized machines address unique requirements, such as polishing irregularly shaped tubes or those with intricate designs.

Factors Driving Popularity

Several factors contribute to the growing demand for tube polishing machines in India

- Industrial Growth With India emerging as a global manufacturing hub, there is an increasing need for advanced machinery to meet production standards. Industries such as automotive and aerospace are expanding, which drives the need for high-quality tube products.

- Technological Advancements The introduction of new technologies in polishing processes has further enhanced the efficiency and effectiveness of tube polishing machines. Automation and robotics are becoming more prevalent, allowing for greater precision and speed.

- Quality Standards As regulatory standards become more stringent, manufacturers are compelled to invest in equipment that ensures the highest quality of finished products. Tube polishing machines help meet these standards, making them a critical investment.

- Export Opportunities India’s growing reputation as a manufacturer of quality metal products has opened up export opportunities. To stay competitive in the global market, producers must ensure that their products not only meet but exceed international quality standards, which often necessitates advanced polishing equipment.

Conclusion

In conclusion, tube polishing machines are an integral part of the manufacturing landscape in India. Their ability to enhance product quality and comply with industry standards makes them essential for businesses looking to thrive in a competitive market. With the continued growth of manufacturing and technological advancements, the future of tube polishing machines in India looks promising, offering exciting opportunities for innovation and expansion. Whether for large-scale production or specialized applications, these machines are sure to play a pivotal role in shaping the industry’s future.