Centerless Finish Grinder Factory Enhancing Precision and Efficiency in Manufacturing

In the fast-evolving world of manufacturing, precision and efficiency are paramount. One of the critical machinery types that play a significant role in achieving these goals is the centerless finish grinder. This specialized equipment is designed to shape and finish cylindrical components with unparalleled accuracy, making it an indispensable asset in various industries.

What is a Centerless Finish Grinder?

A centerless finish grinder is a type of grinding machine that operates without the use of centers to hold the workpiece. Instead, it utilizes a combination of a grinding wheel, a regulating wheel, and a workpiece support, allowing it to grind components with a high degree of precision and consistency. This unique setup enables the grinding of long, slender parts that might be challenging to handle using conventional grinding machines.

The process is divided into two main types infeed grinding and through-feed grinding. Infeed grinding is particularly useful for parts with complex shapes or specific diameters, while through-feed grinding is ideal for producing components in large volumes, such as rods and bars.

Advantages of Centerless Grinding

One of the primary advantages of centerless finish grinding is its ability to achieve tight tolerances, which is crucial for industries like automotive, aerospace, and medical devices. The precision of centerless grinding ensures that the finished product meets stringent specifications and operates safely and efficiently in its application.

Additionally, centerless grinding is an incredibly fast process. The machine can handle multiple parts simultaneously, drastically reducing production times. This efficiency leads to lower manufacturing costs and provides companies with a competitive edge in the market.

Moreover, the versatility of centerless grinders allows manufacturers to handle a wide range of materials, including metals, plastics, and composites. Whether it's stainless steel for automotive parts or aluminum for aerospace applications, centerless grinders can be adapted to meet varying material characteristics and hardness levels.

centerless finish grinder factory

Importance of Quality Control

In a centerless finish grinder factory, quality control is a fundamental aspect of the manufacturing process. Ensuring that each component meets the required specifications involves several stages of inspection and testing. State-of-the-art measurement tools, such as laser micrometers and CMM (Coordinate Measuring Machines), are employed to monitor the size, roundness, and surface finish of the parts.

Additionally, factories often implement lean manufacturing principles to minimize waste and ensure efficient use of resources. By focusing on continuous improvement, these factories can enhance product quality while also maintaining production efficiency.

The Future of Centerless Grinding

As technology advances, the future of centerless finish grinder factories looks promising. The integration of automation, artificial intelligence, and Industry 4.0 practices is transforming manufacturing processes. Smart factory setups enable real-time monitoring and predictive maintenance, helping to reduce downtime and optimize production schedules.

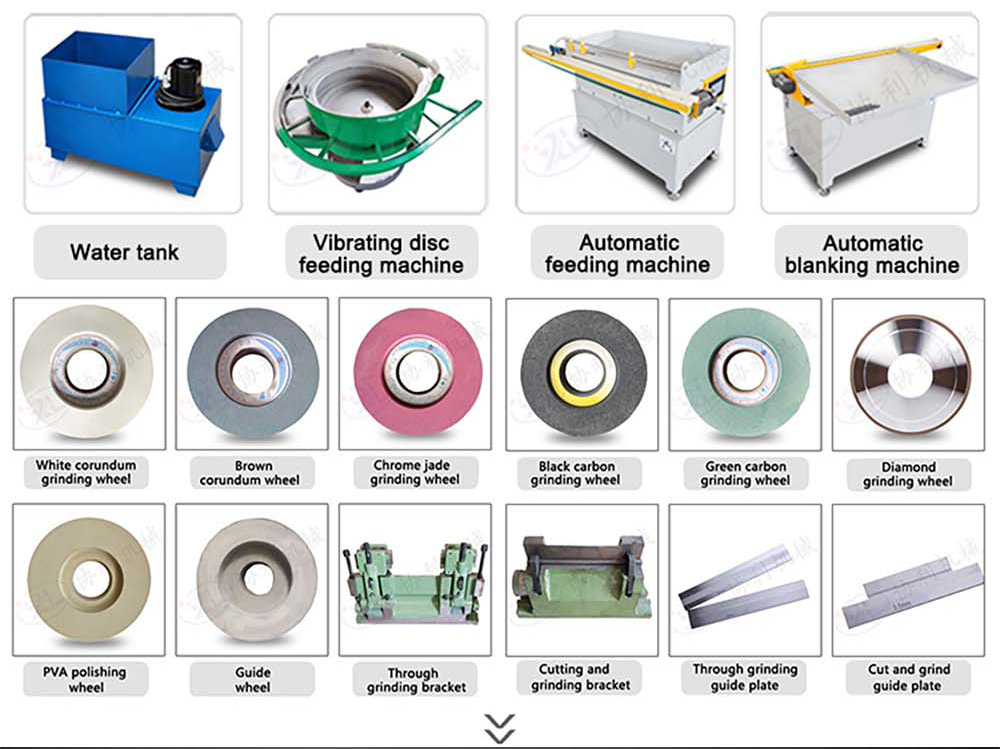

Furthermore, advancements in grinding wheel technology and materials are leading to improved performance and longevity of the grinding tools, which in turn enhances the overall efficiency of the grinding process. Manufacturers are increasingly looking to invest in these new technologies, ensuring that they remain at the forefront of the industry.

Conclusion

Centerless finish grinder factories are pivotal in producing precision components for a wide array of industries. By leveraging the benefits of centerless grinding, manufacturers can achieve high efficiency, superior quality, and significant cost savings. As the industry continues to evolve, embracing new technologies and methodologies will be crucial for maintaining competitive advantage. The future of centerless finish grinding promises increased precision and productivity, solidifying its place as a cornerstone of modern manufacturing.