Revolutionizing Industry The Role of Industrial Metal Polishing Machine Companies

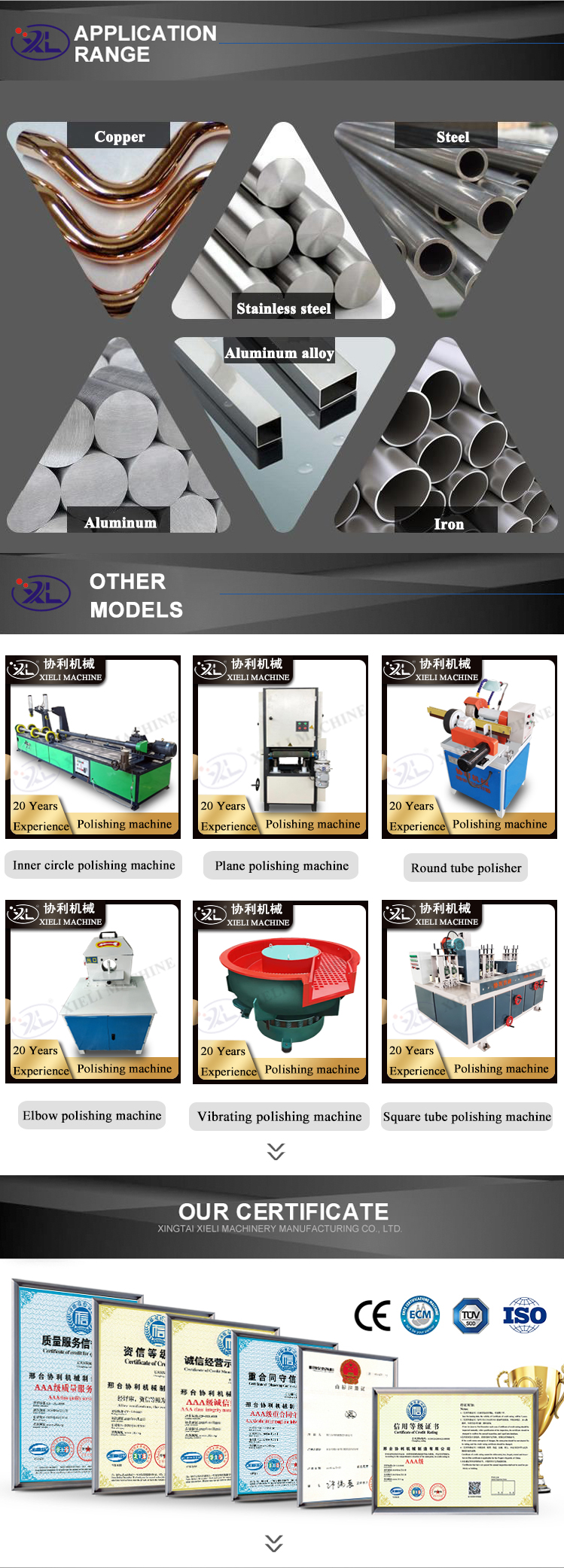

In industries where precision and aesthetics are paramount, the significance of high-quality metal finishing cannot be overstated. Industrial metal polishing machine companies play a crucial role in transforming raw materials into beautifully polished products that meet stringent industry standards. These machines are vital for various sectors, including automotive, aerospace, manufacturing, and decorative applications.

Industrial metal polishing machines are designed to remove imperfections, scratches, and oxidation from metal surfaces, resulting in a smooth, reflective finish. This process enhances not only the appearance of a product but also its durability. A polished finish can protect metals from corrosion and wear, thereby prolonging the life of the component. Consequently, companies invested in high-end production methods often prioritize advanced polishing solutions to ensure maximum efficiency and quality.

The evolution of metal polishing technology has led to the development of sophisticated machinery that can perform consistent, high-speed polishing with minimal human intervention. Automation plays an essential role in modern metal polishing, enabling companies to boost productivity while maintaining high levels of precision. The latest machines utilize techniques such as vibratory finishing, centrifugal barrel finishing, and robotic polishing, each offering unique benefits suited to specific applications.

One of the key advantages of working with an experienced industrial metal polishing machine company is the ability to customize solutions to meet unique manufacturing requirements. These companies often employ engineers and technicians who can collaborate with clients to design tailored polishing systems that enhance production efficiency and product quality. Customization can involve adjusting the type of abrasive materials used, the speed of the polishing process, and the overall design of the equipment to fit specific operational needs.

industrial metal polishing machine company

Moreover, industrial metal polishing machine companies keep pace with industry standards and environmental regulations by focusing on sustainability and eco-friendly practices. Many of these companies are committed to developing machines that consume less energy and utilize non-toxic polishing compounds. This commitment not only helps in reducing the environmental impact of manufacturing processes but also promotes a healthier workplace for employees.

As the industrial landscape continues to evolve, the competitive pressure to produce high-quality polished products has led to further innovation within the sector. Leading companies are investing heavily in research and development to integrate the latest technologies, such as artificial intelligence, into their polishing machines. AI can optimize polishing parameters in real-time, allowing for even greater efficiency and consistency in the polishing process.

Furthermore, globalization has opened new markets for industrial metal polishing machine companies, driving the demand for versatile and effective polishing solutions worldwide. This expansion means that more manufacturers can access state-of-the-art equipment that was once only available to large industries. As a result, smaller manufacturers are now able to compete on a larger scale by producing high-quality polished products for a diverse range of applications.

In conclusion, industrial metal polishing machine companies are at the forefront of a fundamental process that enhances both the aesthetics and functionality of metal products across various industries. With their commitment to innovation, customization, and sustainability, these companies not only meet the demands of their clients but also contribute to the advancement of manufacturing technologies. As industries continue to evolve, the importance of expert polishing services will undoubtedly grow, underscoring the central role of these companies in the modern industrial landscape.