The Evolution and Significance of Famous Bar Polishing Machines

In the world of metal manufacturing and finishing, the quality of the final product often hinges on the effectiveness of the polishing process. When it comes to bar stock—used in a plethora of applications from construction to aerospace—having a perfectly polished finish not only enhances aesthetic appeal but also improves corrosion resistance and overall performance. The famous bar polishing machine has evolved significantly over the years, becoming an indispensable tool in the industry.

Historical Context

The origins of metal polishing can be traced back to ancient civilizations where artisans manually polished metals to achieve a desired sheen. However, as industrialization took hold in the 19th century, the need for faster and more efficient polishing methods emerged. Early machines were rudimentary, relying mostly on manual labor and simple mechanical systems. Over time, with advancements in technology and an increasing demand for precision finishes, specialized bar polishing machines were developed.

Types of Bar Polishing Machines

Today, bar polishing machines come in various types, each designed to cater to specific polishing needs. The two main categories are mechanical polishing machines and chemical polishing systems. Mechanical polisher machines typically involve abrasive belts, brushes, or wheels that mechanically remove surface imperfections. These machines are known for their efficiency and ability to produce a consistent finish quickly.

On the other hand, chemical polishing systems utilize reactive solutions to achieve a smooth surface. They are particularly favored when working with delicate materials or intricate designs where physical abrasion might be inappropriate. This versatility allows manufacturers to select a polishing method that best suits their requirements.

Key Features

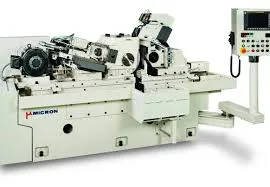

Modern bar polishing machines are characterized by innovations that maximize efficiency and finish quality. Features such as programmable control systems, automated feeding mechanisms, and advanced sensor technologies provide manufacturers with greater oversight and the ability to achieve precise finishes. Furthermore, many units are designed to accommodate various bar sizes and materials, enhancing their usability across different manufacturing environments.

famous bar polishing machine

Environmental considerations are also being integrated into contemporary machine designs. Many manufacturers now offer machines that minimize waste production and reduce harmful emissions, aligning with global sustainability goals. This trend is crucial, as regulatory standards for industrial operations become more stringent.

Market Leader

Among the various manufacturers, certain names have become synonymous with high-quality bar polishing machines. Companies like WMW Machinery, Boschi, and Timesavers are renowned for their state-of-the-art polishing solutions. These manufacturers not only supply equipment but also offer comprehensive support and training programs to ensure that clients can maximize machine efficiency and output quality.

The Future of Bar Polishing Machines

Looking forward, the bar polishing machine industry is poised for further advancements. The integration of artificial intelligence and machine learning technologies promises to enhance operational efficiency and product quality. Smart machines that can self-optimize based on real-time feedback will likely become the norm.

Moreover, as industries continue to embrace automation, the demand for fully automated bar polishing systems will rise. These systems can significantly reduce labor costs while increasing throughput, making them highly appealing to manufacturers aiming for competitive advantage.

Conclusion

The evolution of the famous bar polishing machine reflects broader trends in manufacturing towards automation, efficiency, and sustainability. As technology continues to advance, these machines will play a crucial role in meeting the ever-increasing standards for quality in metal finishing. In doing so, they not only enhance product performance but also support the future of manufacturing in a rapidly changing world.