Navigating the realm of inner wall polishing machines can be a transformative journey for industries that necessitate precision and efficiency in their manufacturing processes. With a focus on delivering unparalleled quality, inner wall polishing machine exporters are playing a crucial role in reshaping operational dynamics across diverse sectors, including automotive, aerospace, and heavy machinery manufacturing. In this detailed exploration, we delve into the facets that make these exporters an indispensable ally in industrial excellence, while simultaneously optimizing for SEO in the most effective manner.

The foremost advantage brought forth by these exporters is their deep-seated expertise in understanding the nuanced demands of global markets. With the ability to cater to varying industrial standards and requirements, these exporters leverage state-of-the-art technology and their extensive know-how to deliver solutions that are both robust and reliable. Their equipment not only addresses the unique challenges posed by different types of metals and surfaces but also accommodates a wide range of sizes, contours, and complexity levels involved in modern manufacturing.

When assessing inner wall polishing machine exporters, one notable aspect is their commitment to innovation and continuous improvement. By investing in research and development, exporters ensure that their machines are equipped with the latest technological advancements. This enhances operational efficiency while minimizing downtime, resulting in significant cost savings for clients. Additionally, many exporters offer customization options tailored to the specific needs of businesses, further affirming their role as pioneers in the field.

The expertise of these exporters is further highlighted by the comprehensive training and support they provide. Understanding that the successful implementation of their machines extends beyond the initial purchase, exporters emphasize extensive training programs for their clients. By empowering operators with the necessary skills and knowledge, exporters ensure optimal utilization of their machines, thereby improving productivity and longevity.

Authoritativeness in the industry is another attribute where inner wall polishing machine exporters excel. By participating in international trade fairs, industry conferences, and workshops, they consistently stay abreast of industry trends and emerging technologies. This level of engagement not only positions them as thought leaders but also enables them to anticipate future market shifts and technological advancements, keeping their clients one step ahead in a competitive landscape.

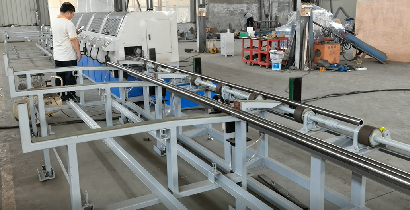

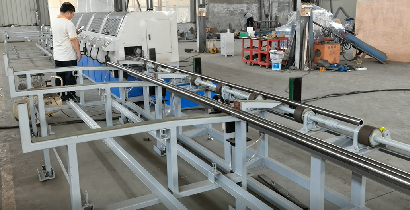

inner wall polishing machine exporters

Trustworthiness, an essential pillar in any business relationship, is upheld by exporters through transparent communication and ethical business practices. Clients can rely on exporters for clear and honest information about product capabilities, pricing, and maintenance. Moreover, compliance with international safety and environmental standards speaks volumes about their dedication to delivering quality without compromising on responsibility towards the planet and society.

The invaluable experience gained by seasoned exporters is evident in their comprehensive understanding of logistical and regulatory challenges associated with international trade. They manage complexities such as customs documentation and shipping logistics, ensuring that their machines arrive at their destination safely and within the stipulated time frame.

To encapsulate, the role of inner wall polishing machine exporters extends beyond mere transaction facilitators; they act as strategic partners guiding industries towards operational excellence. Their dedication to quality, innovation, and client-centric service redefines the standards of industrial manufacturing. As industries continue to evolve, the partnership with a proficient exporter becomes imperative, not only to stay competitive but to lead with fortitude and foresight.

With every polished surface they help create, these exporters are indeed smoothing the path to a brighter future in industrial advancement. For businesses striving to achieve the zenith of precision and production efficiency,

the choice of a trusted inner wall polishing machine exporter is unequivocally a step towards enduring success.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.