Understanding Infeed Centerless Grinders An Overview

In the world of precision machining, centerless grinders play a pivotal role in the production of cylindrical parts. These machines are designed to grind workpieces without the need for centering, thus enabling efficient and high-volume production. Among the various designs, infeed centerless grinders stand out due to their unique capabilities and applications.

What is an Infeed Centerless Grinder?

An infeed centerless grinder is a specific type of centerless grinder utilized primarily for processing parts with various diameters and lengths. Unlike through-feed grinders, which are suited for continuous workpieces, infeed grinders are designed for parts that require precise control over the grinding process, often involving complex shapes or specific profiles.

Infeed centerless grinding facilities incorporate two wheels, namely the grinding wheel and the regulating wheel, which work in harmony. The grinding wheel is responsible for material removal, while the regulating wheel controls the part's rotation and feed rate. This dual mechanism allows for exceptional precision in achieving required tolerances, surface finish, and geometric integrity.

Key Features of Infeed Centerless Grinders

1. Versatility Infeed centerless grinders can accommodate varying part sizes and shapes, making them suitable for a wide range of applications. Whether dealing with short, taper-turned pieces or longer bar stock, these machines can be adapted to meet specific processing needs.

2. Precision Control The infeed process allows the operator to control the depth of cut, offering a more precise approach to grinding. This degree of control is crucial when working with intricate components or when the final dimensions are tightly controlled.

3. Efficiency Infeed centerless grinders are capable of operating at high speeds, leading to increased productivity. The continuous nature of the grinding process allows for faster material removal, which is particularly beneficial in high-volume manufacturing environments.

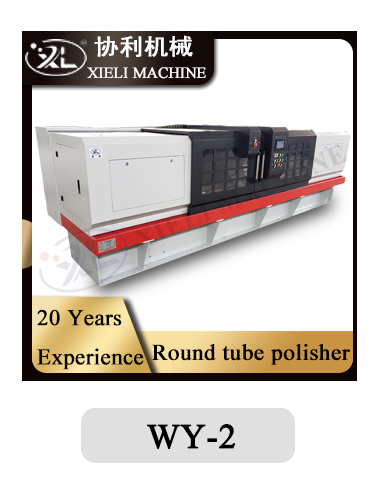

infeed centerless grinder products

4. Reduced Setup Times With advanced technology and tooling, modern infeed centerless grinders have minimized setup times, allowing for quicker transitions between different workpieces. This flexibility is essential for manufacturers who need to adapt to varying production demands without incurring significant downtime.

Applications of Infeed Centerless Grinders

Infeed centerless grinders are favored in various industries, including automotive, aerospace, and medical manufacturing. Some common applications include

- Camshafts and Crankshafts These components require precise tolerances and surface finishes, making infeed grinding an ideal process. - Rollers and Spindles The ability to grind small and large diameters makes infeed grinders suitable for creating rollers and spindles for various machinery. - Fasteners Nuts, bolts, and other fasteners can be effectively processed using infeed centerless grinding techniques due to the need for uniformity and precision.

Advantages of Using Infeed Centerless Grinders

The adoption of infeed centerless grinding technology offers numerous advantages to manufacturers, such as

- Improved Surface Finish The grinding process yields a superior surface finish compared to other machining methods, reducing the need for secondary operations. - Consistent Quality With automated feeds and precise control, the quality of the finished parts remains consistent throughout the production run. - Cost-Effectiveness Although the initial investment may be higher, the efficiency gains, reduced cycle times, and lower labor costs ultimately contribute to lower overall manufacturing costs.

Conclusion

Infeed centerless grinders are a crucial component in the landscape of precision machining. By understanding their design, application, and advantages, manufacturers can optimize their machining processes to ensure high-quality outputs while maximizing efficiency. As technology continues to evolve, the capabilities of infeed centerless grinders will only enhance, paving the way for even greater advancements in industrial manufacturing.