Infeed Centerless Grinder Manufacturers A Comprehensive Overview

In the realm of precision machining, centerless grinders play a pivotal role, particularly when it comes to achieving high efficiency and accuracy in the production of cylindrical parts. Among various types of centerless grinders, infeed centerless grinders are specialized machines designed to handle specific applications where the workpiece is fed into the grinding wheel at a fixed position. This article explores the significance of infeed centerless grinder manufacturers, the technology involved, and the benefits they bring to various industries.

Understanding Infeed Centerless Grinding

Infeed centerless grinding differs from other grinding processes by allowing the workpiece to be ground at a fixed point, rather than being continuously fed through the machine. This method is ideal for components that require a specific shape and precision. The process involves two wheels the grinding wheel and the regulating wheel. The grinding wheel removes material from the workpiece, while the regulating wheel controls its speed and position.

Infeed centerless grinders are particularly beneficial for processing workpieces with complex geometries, such as camshafts, pins, and specialized fasteners. The ability to grind multiple features in a single setup diminishes production times and ensures a higher level of precision.

The Role of Manufacturers

The demand for infeed centerless grinders has surged in various sectors, including automotive, aerospace, medical devices, and manufacturing. As a result, there are numerous manufacturers specializing in these machines, each offering unique features and advantages. The primary role of these manufacturers is to design and produce machines that cater to the specific needs of their customers while ensuring optimal performance and reliability.

Leading infeed centerless grinder manufacturers utilize advanced technologies such as CNC (Computer Numerical Control) programming, which increases automation and precision in the grinding process. CNC technology allows for easier programming of complex grinding patterns, ultimately reducing setup times and improving part consistency. Manufacturers are also focused on integrating smart technology for real-time monitoring and diagnostics, which enhances productivity and reduces downtime.

Key Features to Consider

When selecting an infeed centerless grinder manufactured by a reputable company, there are several key features to consider

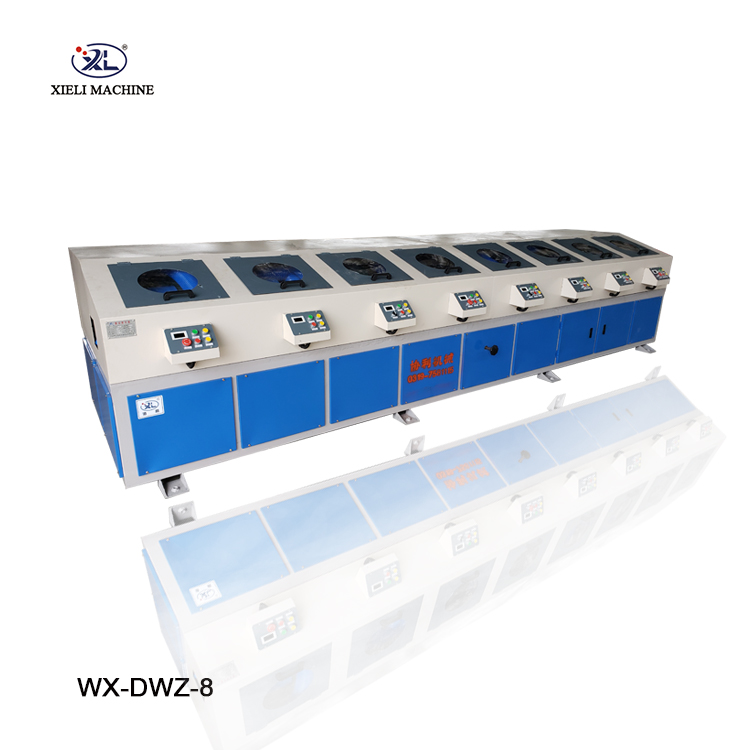

infeed centerless grinder manufacturer

1. Precision and Accuracy The machine must deliver consistent results with minimal tolerances, as precision is crucial in industries where even the slightest deviation can lead to significant issues.

2. Material Compatibility The grinding machine should be capable of handling a variety of materials, including metals, polymers, and composites, to accommodate different production requirements.

3. Ease of Use User-friendly control systems are vital for ensuring operators can efficiently set up and operate the machine.

4. Automation Capability Manufacturers that incorporate automation technology can significantly enhance productivity by reducing manual input and allowing for unattended operation.

5. Maintenance and Support Reliable after-sales service and access to spare parts are essential factors to consider, as they can affect the operational efficiency of the grinding machines over time.

Benefits of Infeed Centerless Grinders

The advantages of using infeed centerless grinders manufactured by industry leaders cannot be overstated. These grinders provide a perfect balance of speed, efficiency, and precision. They are designed to reduce cycle times significantly, which is especially beneficial for high-volume production runs. Furthermore, they minimize material waste, contributing positively to the overall cost per unit produced.

Infeed centerless grinding also enhances the quality of the finished products. The ability to maintain tight tolerances ensures that components fit together seamlessly, which is crucial in applications like engine manufacturing and medical device assembly.

Conclusion

Infeed centerless grinder manufacturers are integral to the success of industries that rely on precision machining. By focusing on technology, automation, and rigorous standards of reliability, these manufacturers help businesses produce high-quality components efficiently. As technology evolves, so too will the capabilities of infeed centerless grinders, further solidifying their role as a cornerstone of modern manufacturing. Engaging with reputable manufacturers can empower companies to achieve their production goals and maintain a competitive edge in their respective markets.