Infeed Centerless Grinder Factory Precision Engineering at Its Best

In the realm of manufacturing, precision is paramount, and nowhere is this truer than in the operations of an infeed centerless grinder factory. These facilities play a crucial role in producing high-quality components used across various industries, including automotive, aerospace, and medical devices. Developing this technology requires a deep understanding of both the machines involved and the materials being processed.

Understanding Infeed Centerless Grinding

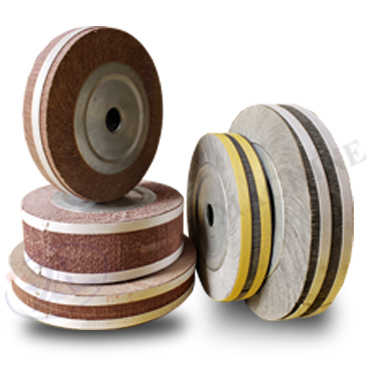

Infeed centerless grinding is a machining process that produces cylindrical parts without the need for a supporting structure. Unlike traditional grinding methods, which typically require a fixture or support, centerless grinding utilizes a unique setup involving three key components two grinding wheels and a regulating wheel. The workpiece is fed into the grinding zone and held in place by the regulating wheel, which allows for precise control over the grinding process.

The infeed method is particularly advantageous for manufacturing parts with complex geometries, as it can accommodate variations in size more effectively than other grinding techniques. This flexibility allows manufacturers to produce parts with tight tolerances, enhancing the overall quality of the final product.

The Factory's Role in Production

A typical infeed centerless grinder factory is equipped with advanced machinery and technology to ensure optimal production efficiency. The grinding machines are designed for high-speed operation, allowing for minimal cycle times and increased throughput. An efficient layout within the factory promotes smooth workflows, reducing waiting times and optimizing the use of resources.

At the core of any successful factory is a skilled workforce. Operators and technicians undergo extensive training to master the intricacies of centerless grinding equipment and maintain tight tolerances consistently. With a strong commitment to quality assurance, many factories implement rigorous inspection processes throughout the production cycle. Automated quality control systems often utilize laser measurement technology and vision systems to ensure that each part meets the required specifications before it leaves the factory.

infeed centerless grinder factory

Emphasizing Innovation and Technology

The world of manufacturing is ever-evolving, with advancements in technology shaping the way components are produced. In an infeed centerless grinder factory, automation has become a critical component, streamlining processes and reducing human error. Integrating computer numerical control (CNC) systems allows for enhanced precision and repeatability, enabling factories to produce high-quality parts with minimal variation.

Moreover, the shift towards Industry 4.0 principles has encouraged factories to adopt data-driven decision-making processes. By utilizing the Internet of Things (IoT), manufacturers can monitor machinery performance in real-time, predict maintenance needs, and optimize production flows. This level of connectivity not only improves operational efficiency but also fosters a culture of continuous improvement.

Environmental Considerations and Sustainability

In addition to innovation, today's manufacturing environment places significant emphasis on sustainability. Many infeed centerless grinder factories are now implementing eco-friendly practices to minimize waste and reduce their carbon footprint. Techniques such as recycling grinding coolant, optimizing energy consumption, and utilizing biodegradable materials are becoming increasingly common.

By focusing on environmentally responsible practices, these factories not only enhance their efficiency but also contribute positively to the well-being of the planet. As customers increasingly demand greener products, manufacturers who prioritize sustainability will undoubtedly find themselves at a competitive advantage in the marketplace.

Conclusion

The infeed centerless grinder factory exemplifies the intersection of precision engineering and innovative technology. As these factories continue to adapt to shifting market demands and technological advancements, they play an essential role in the broader landscape of modern manufacturing. By prioritizing quality, efficiency, and sustainability, they are not only meeting the needs of today's industries but also paving the way for a more responsible and efficient manufacturing future.