Understanding Infeed Centerless Grinder Quotes

Infeed centerless grinding is a specialized manufacturing process that plays a crucial role in various industries, particularly in precision engineering. This method enables manufacturers to grind cylindrical parts without using a spindle, resulting in higher efficiency and reduced setup times. As businesses increasingly seek to optimize their production capabilities, understanding infeed centerless grinder quotes becomes essential.

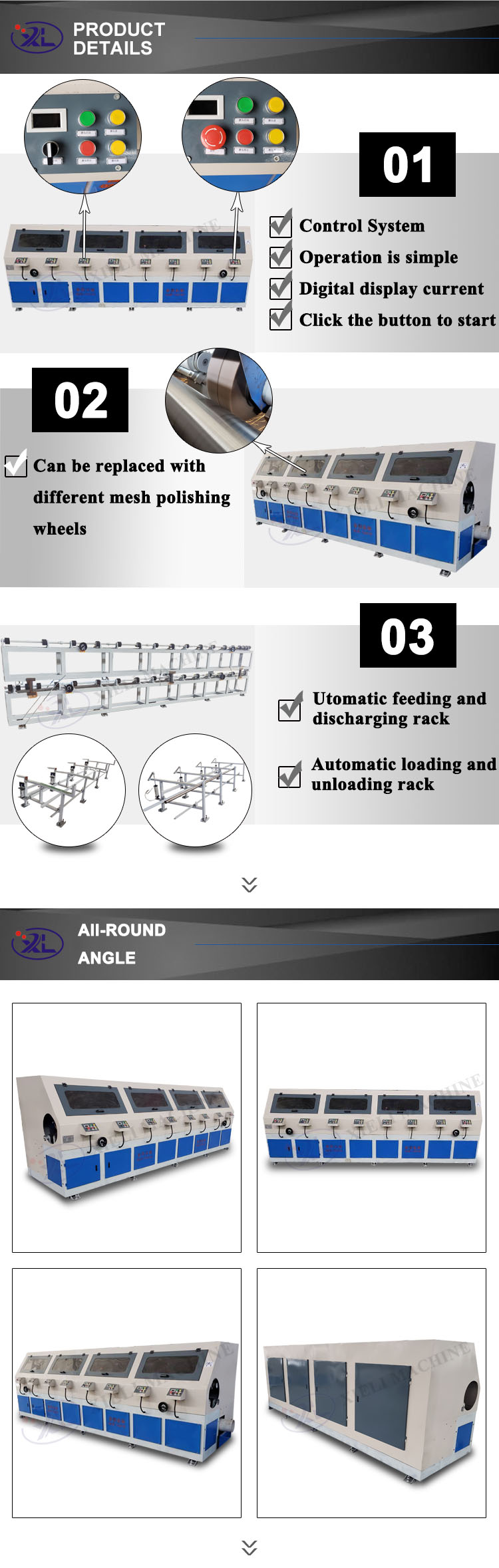

When evaluating quotes for infeed centerless grinders, several factors need to be considered. The first aspect is the specifications of the machine itself. Different manufacturers offer various models, each designed for specific applications. The grinding wheel size, the maximum workpiece diameter, and the power requirements are all critical factors that can influence the quote. Ensuring that the chosen grinder aligns with the production needs is vital for efficient performance.

Another essential component of infeed centerless grinder quotes is the level of automation. Many modern machines come equipped with advanced automation features that not only enhance efficiency but also ensure consistent quality. Automated loading and unloading systems, for instance, can significantly reduce manual labor, thereby cutting down the overall operational costs. It is important to weigh the potential return on investment against the initial costs when considering automated options.

infeed centerless grinder quotes

Additionally, the quotes should reflect the technical support and service agreements provided by the manufacturer. Centerless grinders are complex machines that require regular maintenance and occasional repairs. A quote that includes comprehensive service packages can save businesses significant costs in the long run. Manufacturers that offer training for operators, quick response times for service calls, and accessible spare parts are more likely to be worth considering.

Moreover, comparing quotes from multiple suppliers can lead to better deals. It is essential to look not only at the price but also at the overall value offered. Cheaper quotes might be tempting, but they can come with hidden costs associated with quality and reliability. Always analyze what each quote entails, including warranty options and the reputation of the manufacturer in the market.

In conclusion, acquiring infeed centerless grinder quotes requires a detailed analysis of various factors, including machine specifications, automation features, service agreements, and supplier reputation. By carefully assessing these elements, manufacturers can make informed decisions that will enhance their production processes and ultimately contribute to their bottom line. Investing time in understanding these quotes can lead to significant advantages in the competitive landscape of precision manufacturing.