Exploring Infeed Centerless Grinder Manufacturing

Infeed centerless grinding is a specialized machining process used predominantly in the manufacturing industry to achieve precise dimensions and smooth surfaces on cylindrical workpieces

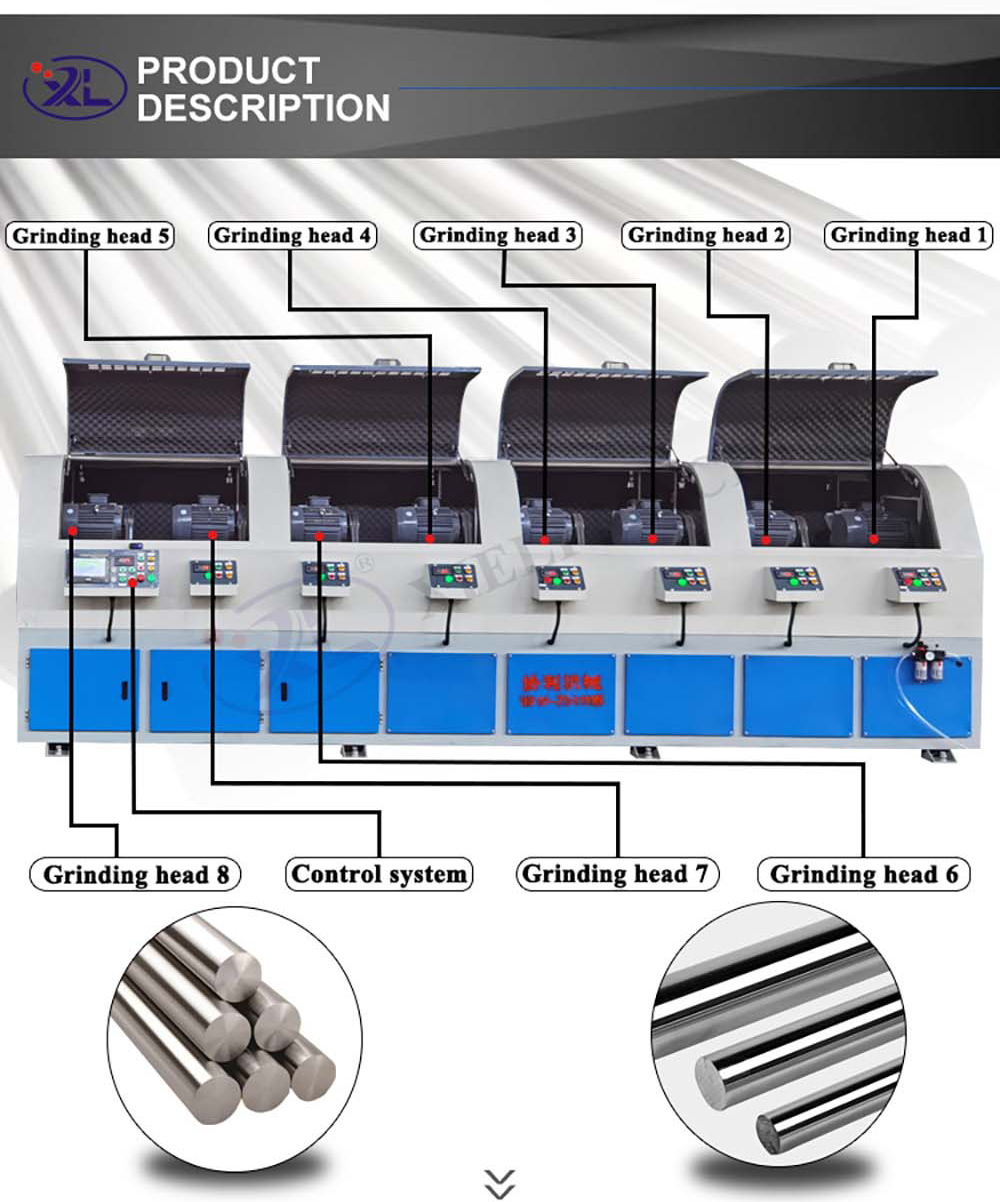

. The factory where these machines are produced plays a critical role in ensuring quality and efficiency. This article delves into the essential components of an infeed centerless grinder factory and the importance of this technology in modern manufacturing.At the heart of any infeed centerless grinder factory is an advanced technological setup. The manufacturing process begins with high-grade raw materials, often steel or other durable alloys, which are essential for producing reliable and long-lasting grinding machines. The factory is equipped with state-of-the-art machinery, including CNC (Computer Numerical Control) machines, which enhance precision and improve production efficiency. These machines enable manufacturers to create complex parts that meet stringent tolerances and specifications.

The infeed centerless grinder itself operates under a unique principle. Unlike traditional grinding processes that require the part to be held at both ends, this type of grinder relies on a combination of wheels positioned in a manner that keeps the workpiece centered during the grinding process. This design not only improves efficiency but also reduces setup times and labor costs. The infeed method allows for various workpiece sizes and shapes, making it a versatile choice for manufacturers.

infeed centerless grinder factory

Quality control is paramount in an infeed centerless grinder factory. Every machine produced undergoes rigorous testing to ensure it meets industry standards and performs exceptionally. This includes checking for vibration, concentricity, and surface finish. The factory often employs skilled technicians who are knowledgeable about both the machines and the materials being used. Their expertise ensures that any potential issues are caught early in the manufacturing process, ultimately leading to higher-quality end products.

In recent years, there has been a growing focus on automation and smart manufacturing technologies within infeed centerless grinder factories. Implementing automated systems helps to streamline production lines and reduce human error. Additionally, the integration of IoT (Internet of Things) devices allows for real-time monitoring of machine performance and predictive maintenance, further increasing efficiency and minimizing downtime.

As industries strive for greater precision and productivity, the demand for high-quality infeed centerless grinders continues to rise. The factories that create these essential machines are at the forefront of innovation, playing a crucial role in shaping the future of manufacturing. Through investment in technology and commitment to quality, infeed centerless grinder factories are set to meet the evolving needs of the global market.