Polishing systems are integral to industrial manufacturing processes that demand clean, smooth, and oxidation-free surfaces. In sectors such as aerospace, shipbuilding, pharmaceuticals, food processing, and high-spec architectural design, stainless steel pipes and tubes must meet both aesthetic and functional standards. This is where cutting-edge pipe polisher and tube polisher technologies play a critical role. These systems not only ensure the highest finish quality but also streamline workflows and reduce manual labor. For manufacturers seeking reliability and efficiency, choosing the right polishing machine is essential to maintaining product integrity and optimizing productivity.

Streamlining Stainless Finishing with High-Performance Pipe Polisher Systems

Modern fabrication shops rely on versatile finishing tools, and a pipe polisher stands out as a core solution for achieving consistent surface refinement. In contrast to manual grinding or sanding, today’s automated polishers enable smooth operation even on long or complex piping. Whether for hygienic tubing in food factories or precision conduits in chemical plants, the pipe polisher operates efficiently across a wide range of diameters and materials. Enhanced with adjustable speed controls, pressure feedback, and automated feed mechanisms, these machines drastically reduce surface irregularities while minimizing human error.

Improving Productivity and Surface Quality with the Right Tube Polisher

From structural tubing to decorative stainless pipes, achieving a uniform finish is essential. This is where a powerful tube polisher contributes immense value to industrial finishing lines. Positioned after cutting or welding stages, these devices prepare tubes for final assembly or coating. For manufacturers in need of high throughput and repeatable results, the tube polisher allows multi-pass polishing without damaging the substrate. Advanced models also offer wet and dry polishing capabilities, improving both surface brilliance and process cleanliness. Whether preparing tubes for electroplating or passivation, these machines deliver professional-grade outcomes every time.

How a Tube Polishing Machine Enhances Surface Integrity in Demanding Applications

Applications in food-grade production, clean rooms, and marine systems require that pipes not only perform but also resist corrosion, contamination, and abrasion. Here, a well-engineered tube polishing machine ensures that every inch of the tube is free of pits and micro-scratches. Integrated with multiple polishing stations, pressure control sensors, and programmable logic controllers (PLC), a tube polishing machine provides hands-free operation and consistency across production cycles. These machines are designed to handle diverse surface finishes such as satin, mirror, or brushed, giving manufacturers full control over their end product aesthetics.

What Sets a Tube Polishing Machine Manufacturer Apart in Industrial Supply Chains

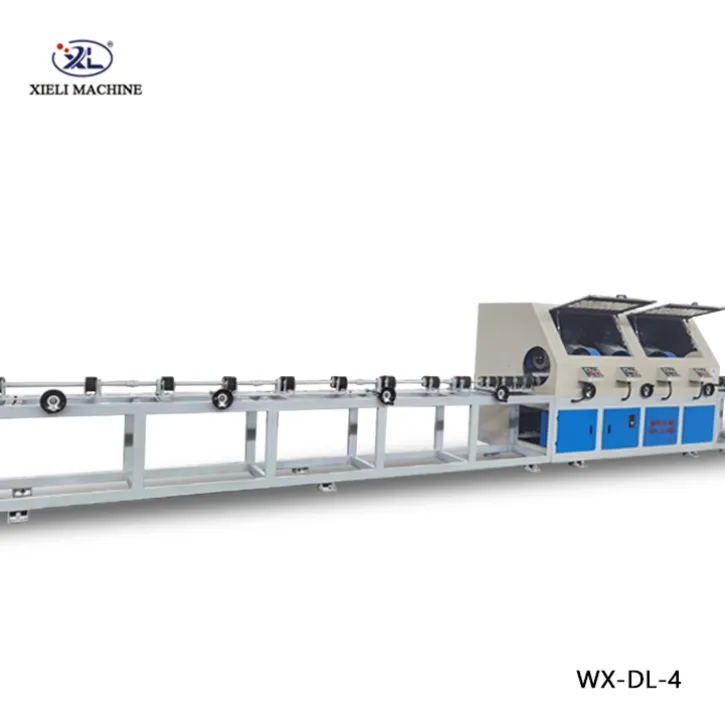

Finding a reliable tube polishing machine manufacturer goes beyond simple procurement—it’s about building long-term partnerships rooted in precision, support, and customization. In competitive sectors like industrial fabrication, manufacturers seek suppliers who offer robust machinery along with application-specific solutions. A quality-focused tube polishing machine manufacturer typically provides customizable head configurations, easy integration with existing conveyor systems, and post-installation technical support. This combination ensures uninterrupted operation even under high-volume conditions, and guarantees the machine aligns with unique processing needs.

Choosing a Pipe Polishing Machine Manufacturer for Optimized Finishing Efficiency

Industries looking to scale polishing operations efficiently must assess the credibility and expertise of each pipe polishing machine manufacturer before investing. The best manufacturers are those who not only supply equipment but also understand real-world applications and user pain points. An innovative pipe polishing machine manufacturer develops systems capable of 360-degree polishing, inside diameter (ID) and outside diameter (OD) treatments, and variable pressure control. Additionally, these manufacturers often provide safety compliance certification and rigorous testing documentation—critical for heavy industries with strict quality control benchmarks.

Benefits of Industrial-Grade Polishing Machines Over Manual Methods

Industrial polishing systems vastly outperform manual tools in both speed and finish quality. Automated systems ensure uniform results across production batches, minimize downtime, and significantly reduce operator fatigue. This makes them ideal for high-precision environments.

How Tube and Pipe Polishers Contribute to Corrosion Resistance

By removing surface imperfections, oxide layers, and embedded contaminants, polishing systems greatly improve corrosion resistance. Smooth surfaces are less likely to trap moisture or react with chemicals, extending the lifespan of industrial piping.

Integration Tips for New Tube Polishing Equipment in Existing Facilities

Before integrating a new machine, assess your current workflow, space layout, and power requirements. Choose models that offer modular installation and compatibility with existing conveyors or finishing lines for minimal disruption during upgrades.

Pipe and Tube Polishing Solutions FAQs

Q: What materials can a pipe polisher work on in industrial environments?

A: Most industrial pipe polishers are designed to handle stainless steel, aluminum, copper, and carbon steel. Some advanced models also support non-metallic materials with the right abrasive configuration.

Q: How does a tube polishing machine differ from a basic tube polisher?

A: A basic tube polisher is often handheld or semi-automated, while a full tube polishing machine is a dedicated station equipped for high-volume, automated polishing with multiple heads and feed systems.

Q: What factors should be considered when choosing a pipe polishing machine manufacturer?

A: Look for manufacturers with strong industrial references, machine customization capabilities, integrated automation features, and post-purchase support such as training and spare parts availability.

Q: Can polishing machines help meet regulatory compliance in food and pharmaceutical industries?

A: Yes. Polished surfaces are required to be smooth and cleanable to meet FDA, GMP, or 3A standards. Automated polishing ensures consistent surface quality that meets these requirements.

Q: What is the typical maintenance requirement for tube polishing machines?

A: Regular maintenance includes belt or brush replacement, lubrication of moving parts, software updates (if applicable), and periodic alignment checks. A good manufacturer provides a maintenance manual with schedules.