In industrial manufacturing, precision and efficiency are paramount. One of the key tools that contribute significantly to these goals is the centerless grinding machine. This equipment allows for high-accuracy finishing of cylindrical parts without the need for centers or chucks, making it indispensable in high-volume production environments. But how does the centerless grinding machine price affect a company’s investment decision and operational efficiency? Understanding the balance between cost and performance can help manufacturers choose the right grinder to meet their exact production needs. This article explores various aspects of centerless grinding machine price and related topics, offering valuable insights for industrial buyers and engineers.

Evaluating the Centerless Grinder Price in Relation to Industrial Needs

When considering a centerless grinder price, industrial buyers must evaluate how the machine’s capabilities align with production demands. Although cheaper models may be tempting, they often lack the precision, durability, or automation features required for large-scale or specialized grinding tasks. Conversely, higher-priced grinders typically include advanced control systems, enhanced spindle designs, and superior wheel mechanisms that improve part consistency and reduce cycle times. It’s essential to assess how each element of the centerless grinder price corresponds to the expected return on investment, including reduced scrap rates and increased throughput.

Understanding Centreless Grinding Machine Price Variations Across Markets

The centreless grinding machine price can vary widely depending on geographic markets, manufacturer specifications, and technological advancements. In some regions, import tariffs and shipping costs influence final prices significantly. Additionally, machine customization, such as size, automation levels, and integration with Industry 4.0 systems, also impact the centreless grinding machine price. Industrial buyers should conduct thorough market research and consult detailed sources like the centreless grinding machine ppt materials available from trusted technical suppliers to better understand cost components and potential operational advantages.

Leveraging Centreless Grinding Machine PPT for Informed Purchasing

Industrial procurement teams often rely on technical presentations, such as the centreless grinding machine ppt, to understand operational principles, machine specifications, and maintenance requirements. These presentations provide detailed breakdowns of machine functions, including the roles of regulating wheels, grinding wheels, and work rests. Although the centreless grinding machine ppt is educational, it can also clarify why higher prices often correlate with enhanced automation, reliability, and adaptability to different materials. Using such resources, companies can justify investments by highlighting efficiency gains and lower long-term maintenance costs.

Utilizing Centerless Grinding Machine PDF Guides for Maintenance and Optimization

Once a centerless grinder is purchased, ongoing performance depends heavily on proper maintenance and operation. The centerless grinding machine pdf manuals and guides are indispensable tools for technicians and operators. These documents detail troubleshooting steps, recommended lubrication schedules, and setup instructions that ensure optimal grinding precision. Regular consultation of the centerless grinding machine pdf resources can extend the machine’s lifespan, enhance part quality, and reduce downtime, ultimately improving the total cost of ownership despite initial centerless grinding machine price considerations.

Balancing Centerless Grinder Price with Technological Innovation

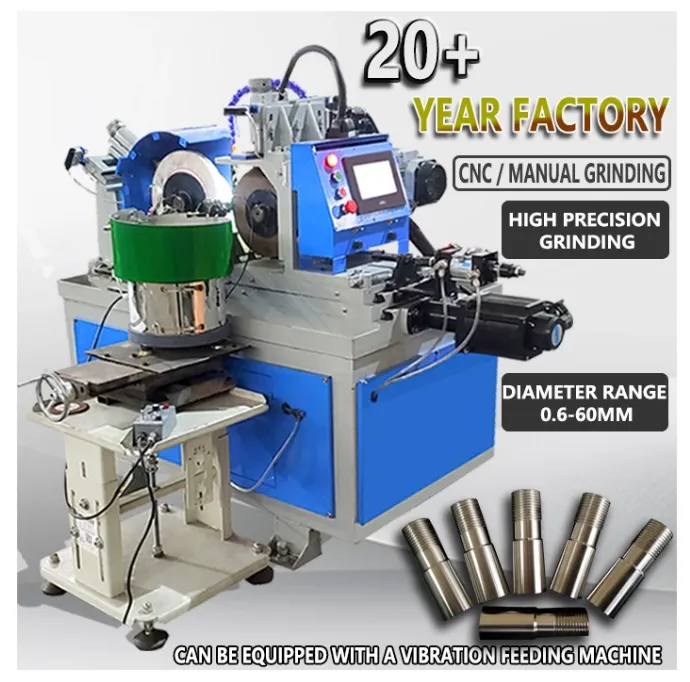

Modern centerless grinders increasingly incorporate technological advancements such as CNC controls, robotic part loading, and real-time monitoring. While these innovations can elevate the centerless grinder price, they also deliver measurable improvements in repeatability and production speed. Advanced features reduce manual interventions, allowing operators to focus on quality control and process optimization. Therefore, the true value of a higher centerless grinder price is often realized through minimized labor costs and enhanced process consistency, crucial for industries requiring tight tolerances and high output.

What Factors Most Influence Centerless Grinding Machine Price?

Several factors drive the centerless grinding machine price, including machine size, automation level, spindle power, and the complexity of control systems. Additionally, the manufacturer’s reputation and after-sales service quality play significant roles in overall value.

How Can Industrial Buyers Use Centreless Grinding Machine PPT to Choose Machines?

Industrial buyers benefit from reviewing centreless grinding machine ppt materials as they provide clear visual explanations of machine components and workflow. These presentations highlight key features to compare across models, aiding informed decision-making beyond just price comparisons.

Is Investing in a High-Priced Centerless Grinder Justifiable for All Industries?

High-priced centerless grinders are especially justifiable in sectors with stringent quality requirements or large production volumes. Industries such as automotive, aerospace, and precision engineering often see rapid ROI due to improved part quality and reduced cycle times.

Centerless Grinding Machine Price FAQs

Q: What is the typical price range for a centerless grinding machine?

A: Prices vary widely depending on size, automation, and brand but generally range from $30,000 to over $150,000 for advanced models.

Q: How does the centerless grinding machine price affect maintenance costs?

A: Generally, higher-priced machines include features that reduce maintenance frequency and cost, such as automated lubrication and self-diagnostic systems.

Q: Can the centerless grinding machine pdf manuals help reduce operational errors?

A: Yes, comprehensive PDF manuals guide operators on correct machine setup and troubleshooting, helping minimize errors and improve productivity.

Q: Are centreless grinding machine ppt resources widely available for buyers?

A: Many manufacturers and technical suppliers provide centreless grinding machine ppt resources online or upon request to aid buyers in understanding machine capabilities.

Q: What is the difference between centerless and centreless grinding machine prices?

A: The terms “centerless” and “centreless” refer to the same technology; price differences are typically due to regional spelling preferences rather than product variations.