The Importance of High-Quality Square Tube Grinding Machines

In the modern manufacturing landscape, the quality of machines used for production plays a crucial role in determining the efficiency, cost-effectiveness, and overall output of manufacturing processes. Among these machines, the square tube grinding machine stands out as an essential equipment for industries specializing in metal fabrication. This article explores the significance of high-quality square tube grinding machines, their features, and their contributions to enhanced productivity and product quality.

Understanding Square Tube Grinding Machines

Square tube grinding machines are specialized tools designed for the grinding and finishing of square or rectangular tubes. These machines serve multiple purposes, including the removal of burrs, surface preparation, and achieving specific surface finishes that meet industry standards. They are widely used in sectors such as automotive, aerospace, construction, and furniture manufacturing. The precise design and engineering of these machines allow for consistent and repeatable results, which are vital in high-volume production environments.

Why Quality Matters

High-quality square tube grinding machines offer various advantages over their lower-quality counterparts. One of the most significant benefits is their reliability and precision. A machine built with robust materials and advanced technology ensures longevity, reducing maintenance costs and downtime. Moreover, high-quality machines provide consistent grinding results, which are crucial for maintaining the specifications required by a customer's design. In contrast, subpar machines may lead to variations in product quality, resulting in increased scrap rates and potential rework costs.

Key Features of High-Quality Grinding Machines

1. Powerful Motors High-quality square tube grinding machines are equipped with powerful motors that enable them to handle heavy loads and operate at high speeds. This feature enhances efficiency and completes tasks quickly, which is crucial in fast-paced manufacturing environments.

2. Precision Engineering The design of these machines is meticulously engineered to achieve high precision. Features such as adjustable settings allow operators to customize the grinding process according to the material and desired finish, ensuring optimal results every time.

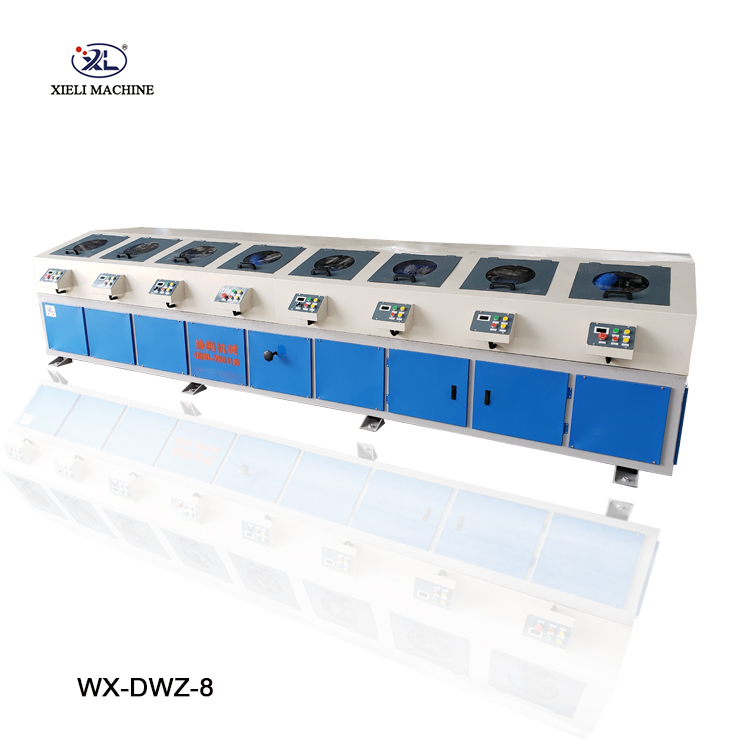

high quality square tube grinding machine

3. Automated Systems Many high-end grinding machines incorporate advanced automation features. These systems help streamline operations and reduce the need for manual intervention, leading to increased productivity and decreased labor costs.

4. Dust Extraction Systems High-quality machines often come with built-in dust extraction systems. This feature not only improves the work environment by reducing airborne particles but also prolongs the life of the machine by keeping vital components free from debris.

5. User-Friendly Interface Modern square tube grinding machines are equipped with intuitive control panels that simplify operation. Features like digital display screens and programmable settings allow operators to efficiently set parameters and monitor the grinding process.

Economic Benefits

Investing in a high-quality square tube grinding machine may require a larger initial capital outlay; however, the long-term benefits often outweigh these costs. Businesses can expect reductions in operational costs due to improved machine efficiency and lower maintenance requirements. Furthermore, the consistency and quality of the output can lead to higher customer satisfaction, repeat business, and referrals, ultimately driving revenue growth.

Conclusion

The role of high-quality square tube grinding machines in the fabrication industry cannot be overstated. As manufacturers strive for increased efficiency, reduced operational costs, and higher product quality, the choice of grinding equipment becomes a critical factor. Investing in a reliable, state-of-the-art square tube grinding machine is not merely about acquiring a tool; it is about enhancing the entire manufacturing process. As the industry continues to evolve, those who prioritize quality and precision in their equipment will undoubtedly lead the way in innovation and market competitiveness.

In summary, the pursuit of excellence in metal fabrication starts with selecting the right tools, making high-quality square tube grinding machines an indispensable asset in any modern manufacturing operation. Whether it is for producing aerospace components or furniture frames, the right grinding machine can make all the difference in achieving superior results and fostering growth in today’s competitive landscape.