High-Quality Paragon Centerless Grinding Machines Precision Engineering at Its Best

In the realm of precision engineering, the quality of machinery plays a pivotal role in ensuring optimal performance and product integrity. One of the frontrunners in this domain is the Paragon Centerless Grinding Machine, a device admired for its ability to deliver superior grinding solutions across various industries.

Understanding Centerless Grinding

Centerless grinding is a method that allows the grinding of cylindrical parts without the need for a supporting center. This innovative process offers several advantages over traditional grinding methods, including increased efficiency, consistent workpiece accuracy, and reduced operational costs. By utilizing a centerless grinder, manufacturers can process large batches of components quickly and seamlessly, making it an essential tool in production environments ranging from automotive to aerospace.

Key Features of Paragon Centerless Grinding Machines

Paragon Centerless Grinding Machines stand out due to their robust construction and state-of-the-art technology. Here are some defining features

1. Precision and Accuracy One of the most critical aspects of any grinding application is the desired precision. Paragon machines are engineered to offer exceptional accuracy in dimensional tolerance. Their precision engineering and advanced controls allow for the tightest tolerances, making them suitable for the most demanding applications.

2. User-Friendly Controls Many Paragon models come equipped with user-friendly digital interfaces that facilitate ease of operation. Operators can quickly adjust settings and monitor performance metrics, which reduces the learning curve and enhances productivity.

3. Versatility These machines are versatile, accommodating a wide range of materials, including steel, aluminum, brass, and plastics. This flexibility makes them ideal for diverse production needs across multiple industries.

4. Durability and Low Maintenance Built to withstand the rigors of high-speed production, Paragon grinding machines boast durable materials and components. Their design minimizes the need for frequent maintenance, leading to lower operational downtime and costs.

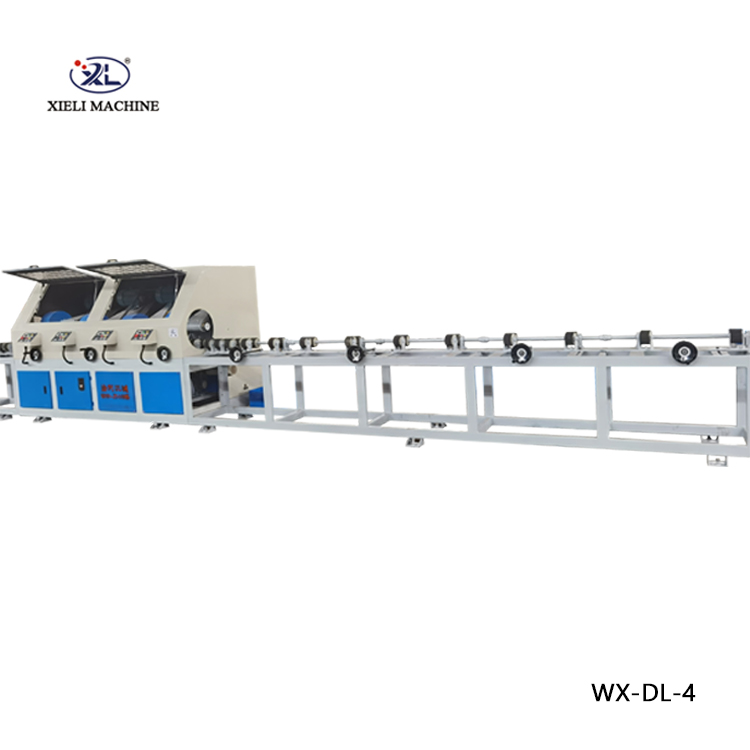

high quality paragon centerless grinding machine

5. Enhanced Cooling Systems Effective cooling during the grinding process is crucial to maintain the integrity of the workpiece and the grinding tools. Paragon machines often feature advanced cooling systems that prolong tool life and improve surface finishes.

Applications Across Industries

The applications of Paragon Centerless Grinding Machines are vast. In the automotive industry, they are commonly used for grinding components such as shafts, bearings, and gears. This capability ensures that critical parts meet stringent quality standards, essential for safety and performance.

In the medical field, precision ground components are vital for manufacturing surgical instruments and implants. Here, Paragon’s machines help produce parts that meet the high levels of precision and hygiene required in this sector.

Additionally, in the aerospace industry, where every component must adhere to rigorous safety and performance standards, the reliability of Paragon’s centerless grinding machines ensures that parts like landing gear and turbine blades are manufactured flawlessly.

Commitment to Innovation

Paragon continuously invests in research and development to enhance its product offerings. They are committed to leveraging advanced technologies such as automation, artificial intelligence, and IoT integration to create smarter grinding solutions. This dedication to innovation enables manufacturers to optimize their processes, reduce cycle times, and achieve higher levels of throughput.

Conclusion

In summary, high-quality Paragon Centerless Grinding Machines exemplify the pinnacle of precision engineering. Their combination of high accuracy, reliability, and versatility makes them a preferred choice for manufacturers across various sectors. As industries continue to evolve, the demand for precise, efficient, and affordable grinding solutions will only grow. By choosing Paragon, businesses not only invest in superior machinery but also in the future of their production capabilities. For excellence in grinding and beyond, Paragon Centerless Grinding Machines set the standard that others strive to meet.