Understanding High-Quality OSHA Centerless Grinders

In the realm of precision manufacturing, centerless grinders play a pivotal role in enhancing productivity and ensuring high-quality finishes on various components. The Occupational Safety and Health Administration (OSHA) has established guidelines that serve to ensure the safe operation of such machinery, which is crucial in minimizing workplace hazards.

Centerless grinders operate on a unique principle where the workpiece is held between two grinding wheels—a regulating wheel and a grinding wheel. The regulating wheel controls the rotation speed, while the grinding wheel performs the actual grinding of the material. The precision involved in this process is essential for machining cylindrical parts to specific dimensions and surface finishes.

Using a high-quality OSHA-compliant centerless grinder is imperative. Compliance with OSHA standards not only ensures a safe working environment but also maximizes efficiency and product quality. High-quality grinders are built with robust materials, advanced technology, and detailed ergonomic designs that prioritize user safety and comfort. These grinders often incorporate features such as automatic shut-off systems, adjustable wheel speeds, and easy maintenance protocols, all of which align with OSHA recommendations.

Safety Features of High-Quality Centerless Grinders

Safety is an essential concern when operating any heavy machinery. High-quality centerless grinders come equipped with several safety features to minimize the risk of accidents. These may include

1. Emergency Stop Buttons Easily accessible stop buttons allow operators to quickly halt the machine in case of any emergency.

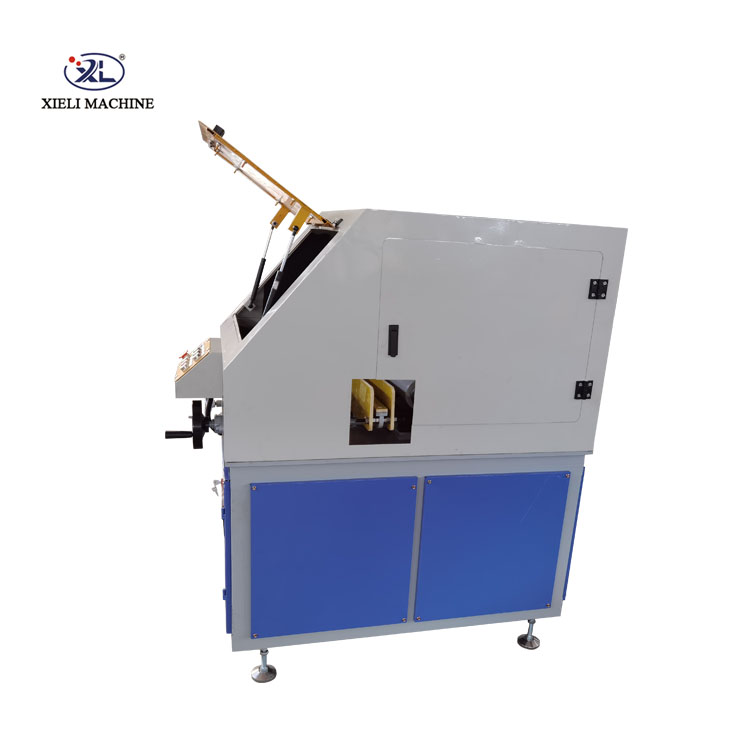

high quality osha centerless grinder

2. Protective Shields Transparent shields protect operators from flying debris while still allowing visibility of the grinding process.

3. Noise Control High-quality grinders often include sound-dampening features to mitigate excessive noise, providing a safer auditory environment for operators.

4. Proper Ventilation Systems These grinders may also possess built-in ventilation systems to reduce harmful dust emissions, which is crucial for maintaining air quality in the workplace.

The Role of Training and Certification

In addition to using high-quality OSHA centerless grinders, proper training for operators is paramount. Workers should be well-versed in the operational procedures, safety protocols, and maintenance practices for the equipment. OSHA offers various training programs and resources to help employers cultivate a knowledgeable workforce that is adept at safely handling grinding machinery.

In conclusion, investing in high-quality OSHA centerless grinders not only enhances operational efficiency and product output but also ensures the safety of workers. By adhering to OSHA guidelines and fostering a culture of safety and education, manufacturers can create a sustainable and productive work environment that benefits both employees and the company as a whole.