High-Quality Jainnher Centerless Grinding Machines Precision and Performance

In the world of manufacturing and machining, precision is paramount. Among the various types of grinding technologies available, centerless grinding stands out due to its efficiency and ability to produce high-quality finishes. Among the leading manufacturers in this field is Jainnher, a company renowned for its high-quality centerless grinding machines.

Understanding Centerless Grinding

Centerless grinding is a technique used extensively in manufacturing to grind cylindrical objects. Unlike traditional grinding processes, where the workpiece is held between two centers, centerless grinding relies on the use of a grinding wheel and a regulating wheel. The workpiece is placed on a work support, allowing it to be ground without the need for additional fixtures. This method allows for continuous production and offers significant advantages, particularly in high-volume work.

Jainnher’s Innovative Design

Jainnher’s centerless grinding machines are designed with the latest advancements in technology, ensuring precision, durability, and ease of use. Their machines are characterized by robust construction and high-performance components that enable them to withstand the rigors of industrial production. With features such as advanced CNC controls, Jainnher machines allow operators to easily set parameters for various grinding processes, enhancing productivity and minimizing downtime.

Precision Engineering

One of the standout features of Jainnher centerless grinding machines is their precision engineering

. These machines can achieve incredibly tight tolerances, making them ideal for industries that require high levels of accuracy, such as automotive, aerospace, and medical manufacturing. Jainnher employs rigorous testing and quality control protocols to ensure that every machine meets strict standards of performance and reliability.Versatility in Application

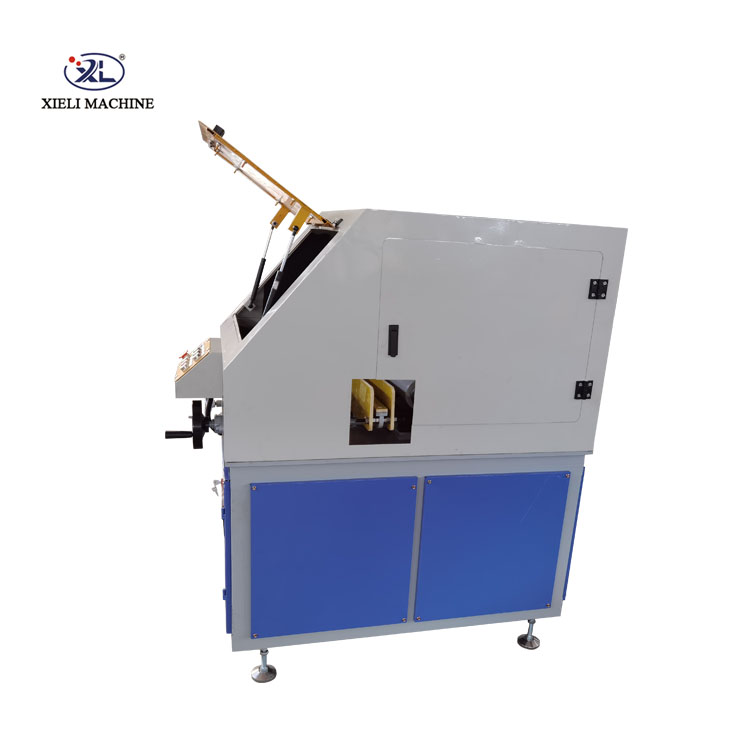

high quality jainnher centerless grinding machine

Jainnher centerless grinding machines are versatile, capable of handling a wide range of materials and sizes. Whether it’s small diameter pipes, larger industrial components, or specialized pieces, these machines can be configured to meet specific requirements. This versatility extends to the types of grinding operations as well, including through-feed, in-feed, and form grinding.

Ease of Maintenance

Another advantage of Jainnher centerless grinding machines is their ease of maintenance. The design includes accessible components that allow for quick and straightforward servicing. Regular maintenance is crucial for maintaining performance and prolonging the lifespan of any grinding machine, and Jainnher understands the needs of their customers in this regard.

Customer Support and Training

Jainnher prides itself on providing exceptional customer support. They offer comprehensive training for operators, ensuring that they are well-versed in the machine's capabilities and maintenance requirements. This investment in customer education helps to maximize the efficiency and productivity of the machines while minimizing the risk of operator error.

Sustainability and Efficiency

In today's manufacturing environment, sustainability is an essential consideration. Jainnher centers its design and production processes around minimizing waste and energy consumption. Their machines are designed to optimize grinding processes, resulting in less scrap and more effective use of materials. This commitment to sustainability also appeals to businesses looking to reduce their environmental impact.

Conclusion

For manufacturers seeking high-quality centerless grinding solutions, Jainnher stands out as an industry leader. Their commitment to innovation, precision, and customer satisfaction makes them an ideal choice for any production environment. Whether you are looking to improve your existing processes or invest in new machinery, Jainnher’s centerless grinding machines promise to deliver outstanding performance and reliability, reinforcing the importance of quality in today's fast-paced manufacturing landscape. By choosing Jainnher, companies can ensure they are equipped with the best tools available for achieving excellence in their machining operations.