High-Quality GP Centerless Grinders The Key to Precision Machining

In the realm of precision machining, the importance of high-quality tools cannot be overstated. Among these, centerless grinders play a pivotal role in delivering superior performance and efficiency. The GP (General Purpose) centerless grinder stands out as a premier choice for manufacturers seeking to enhance productivity without compromising on quality.

What is a Centerless Grinder?

A centerless grinder is a type of grinding machine that uses a rotating grinding wheel to remove material from a workpiece. Unlike traditional grinders, centerless grinders do not require that the workpiece be mounted on a spindle. Instead, the workpiece is fed through the grinding wheel along with a regulating wheel that controls the speed of the workpiece. This unique design allows for a continuous and efficient grinding process, making it ideal for high-volume production.

Advantages of High-Quality GP Centerless Grinders

1. Precision and Accuracy One of the standout features of GP centerless grinders is their ability to maintain tight tolerances. This is crucial for industries where precision is non-negotiable, such as aerospace, automotive, and medical device manufacturing. High-quality grinders are equipped with advanced technology and components that ensure consistent performance and accuracy throughout the grinding process.

2. Increased Productivity With their efficiency, GP centerless grinders significantly reduce production time. The continuous feed mechanism allows for uninterrupted operations, thus maximizing output. Manufacturers can achieve higher production rates without sacrificing quality, leading to improved profitability.

3. Versatility GP centerless grinders are designed to handle a wide variety of workpieces. Whether dealing with small pins or larger shafts, these machines can be easily adjusted to accommodate different sizes and shapes. This versatility makes them an invaluable asset for any manufacturing environment.

4. Reduced Setup Time High-quality GP centerless grinders are engineered for ease of use. They often feature automated setup processes that minimize downtime. This means manufacturers can quickly switch between different jobs, enhancing their operational efficiency.

5. Improved Surface Finish The grinding process in GP centerless grinders results in superior surface finishes compared to other methods. Achieving a smooth and polished finish is essential for many applications, and using a centerless grinder can help meet these standards consistently.

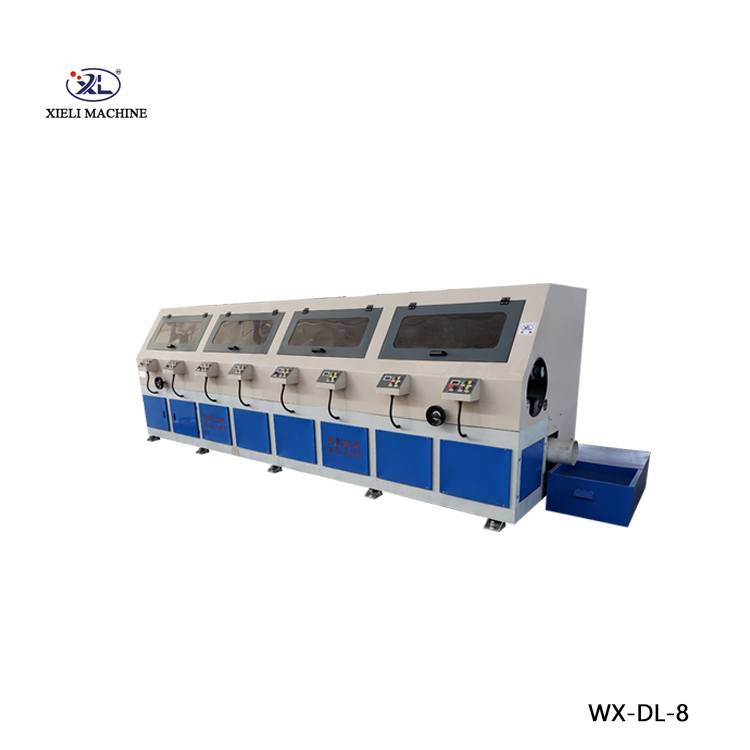

high quality gp centerless grinder

Selecting the Right GP Centerless Grinder

When it comes to choosing a GP centerless grinder, several factors should be considered

1. Machine Specifications Look for grinders with robust specifications, including horsepower, grinding wheel size, and spindle speed. These factors will directly affect the machine's capability and performance.

2. Automation Features such as automatic in-feed and out-feed systems can enhance productivity. Consider investing in advanced automation options that streamline operations and reduce labor costs.

3. Durability and Build Quality A high-quality forge, frame, and components will ensure longevity and reliability. Assess the materials used in the construction of the grinder and opt for designs that withstand rigorous industrial usage.

4. Support and Service Choose a reputable manufacturer that offers excellent customer support and service. This includes assistance with installation, training, and access to spare parts.

5. Cost-Effectiveness While acquiring a high-quality grinder may require a larger initial investment, the long-term savings in time, material costs, and reduced maintenance should not be overlooked.

Conclusion

High-quality GP centerless grinders are essential tools for achieving precision in machining operations. Their advantages—ranging from increased productivity to versatility—make them indispensable in various manufacturing sectors. By investing in a reliable centerless grinder, companies can improve their output, maintain high-quality standards, and ultimately achieve greater success in today's competitive market. Whether you are a small workshop or a large manufacturing facility, understanding the value of high-quality centerless grinders paves the way for operational excellence.