High-Quality Customized Centerless Grinders The Key to Precision Engineering

In the ever-evolving world of manufacturing and engineering, precision and efficiency are paramount. One of the unsung heroes of this industry is the centerless grinder, a specialized machine tool that plays a crucial role in the production of high-quality components. As the demand for tailored solutions grows, so does the importance of high-quality customized centerless grinders. These machines not only enhance productivity but also ensure superior accuracy, making them essential in various industries, from automotive to aerospace.

Understanding Centerless Grinding

Centerless grinding is a machining process that grinds cylindrical parts without the need for a fixed center. This technique involves two wheels the grinding wheel and the regulating wheel. The workpiece is placed between these two wheels, and due to the different rotational speeds and the unique positioning, it achieves precise cylindrical grinding. This method is advantageous for producing parts in high volumes with stringent tolerance levels, making it a preferred choice among manufacturers.

The Benefits of Customized Solutions

While standard centerless grinders serve many purposes, the demand for tailored equipment is on the rise due to specific operational requirements in various industries. Customized centerless grinders offer several advantages

1. Enhanced Precision and Tolerances Customized grinders are designed to meet the exact specifications required by different applications. By integrating unique components and advanced technology, manufacturers can achieve tighter tolerances and superior surface finishes.

2. Increased Productivity Efficiency is key in manufacturing. A customized centerless grinder can significantly reduce cycle times by optimizing the grinding process according to the specific size, shape, and material of the workpieces. This optimization leads to increased throughput and reduced operational costs.

3. Adaptability to Diverse Materials Different materials have varying properties that affect their grindability. Customized centerless grinders can be equipped with specific attachments and features that allow them to handle a range of materials, from metals to plastics, ensuring versatility in production.

4. Ergonomic Design and User-Friendliness Customization can also extend to the design of the machine itself. Ergonomically designed grinders improve operator comfort and safety, while user-friendly interfaces simplify operation and reduce the learning curve for new operators.

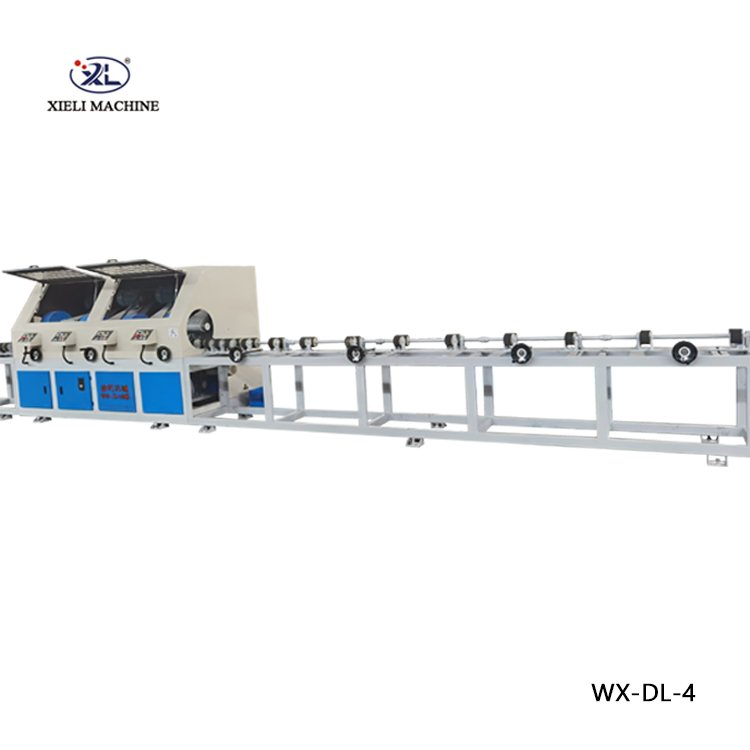

high quality customized centerless grinder

5. Integration with Automation As the industry moves towards greater automation, customized centerless grinders can be designed to integrate seamlessly with existing automation systems. This capability enhances workflow efficiency and reduces the risk of human errors.

Choosing the Right Manufacturer

When investing in high-quality customized centerless grinders, it is crucial to partner with a reputable manufacturer. Here are some factors to consider

- Experience and Expertise Look for manufacturers with a proven track record in designing and producing centerless grinders. Their experience will ensure that they understand the nuances of your requirements and can deliver a reliable solution.

- Technology and Innovation The best manufacturers continuously invest in research and development to incorporate the latest technologies into their machines. This commitment to innovation can significantly enhance the performance and longevity of your grinder.

- Support and Maintenance Services A good manufacturer will offer robust customer support and maintenance services. This support is vital for ensuring that your equipment operates at peak performance and extends its lifespan through regular maintenance.

- Customer Reviews and Testimonials One of the best ways to gauge a manufacturer’s credibility is through customer feedback. Look for reviews and testimonials that highlight the quality of the equipment and the level of service provided.

Conclusion

High-quality customized centerless grinders are indispensable in modern manufacturing. They provide the precision, efficiency, and adaptability needed to meet the challenges of today's competitive landscape. By investing in tailored grinding solutions, manufacturers can not only enhance their productivity but also achieve the level of quality that sets them apart in the industry. As the demand for custom solutions continues to grow, the importance of partnering with a knowledgeable and innovative manufacturer cannot be overstated. With the right equipment, businesses can thrive, pushing the boundaries of what's possible in precision engineering.