When it comes to understanding the intricacies of centerless grinder parts, experience and expertise play pivotal roles in ensuring optimal machine performance and longevity. Centerless grinders are essential tools in the manufacturing industry, used for producing precision components in a variety of shapes and sizes without the need for a center holding fixture. To fully leverage these machines, one must have a comprehensive understanding of their parts and functions.

The core components of a centerless grinder include the grinding wheel, regulating wheel, and the work rest blade.

Each part has a unique role in the grinding process. The grinding wheel is the primary tool that shapes the workpiece. Its quality, material, and condition significantly impact the precision and efficiency of the grinding operation. Regular inspections and maintenance of the grinding wheel are essential to prevent wear and tear that can lead to inefficiencies and increased operational costs.

The regulating wheel, often overlooked, is equally critical. It controls the rotational speed and the feed of the workpiece, ensuring uniformity and precision in the final product. Expert operators understand the importance of selecting the appropriate material and diameter for the regulating wheel, based on the workpiece material and desired outcomes. Proper calibration and alignment are vital to prevent deviations that could compromise product quality.

The work rest blade, positioned between the regulating and grinding wheels, provides support and stability to the workpiece. Its material and positioning are crucial, as they directly influence the grinding precision. Operators with extensive experience recognize the value of high-quality materials such as carbide for the work rest blade, which offers superior durability and wear resistance.

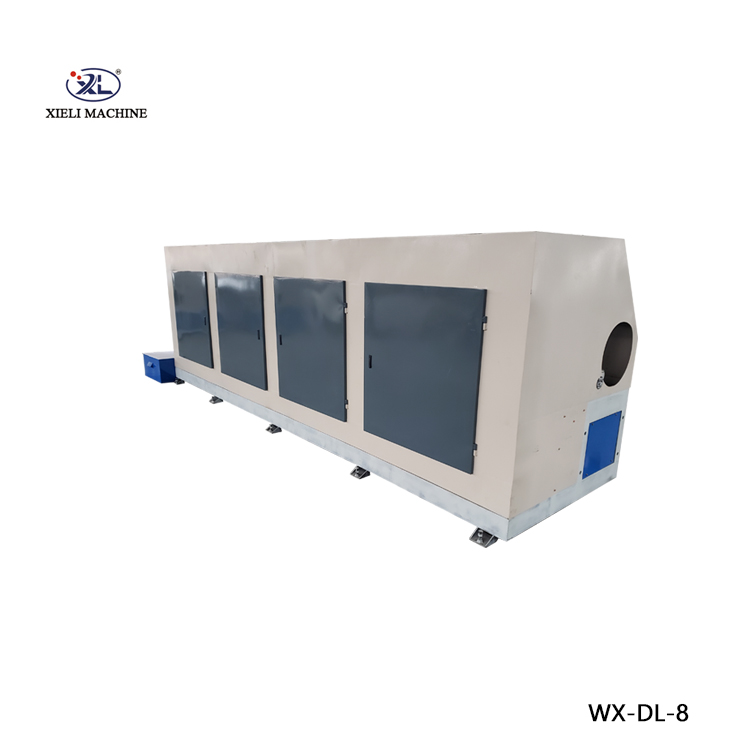

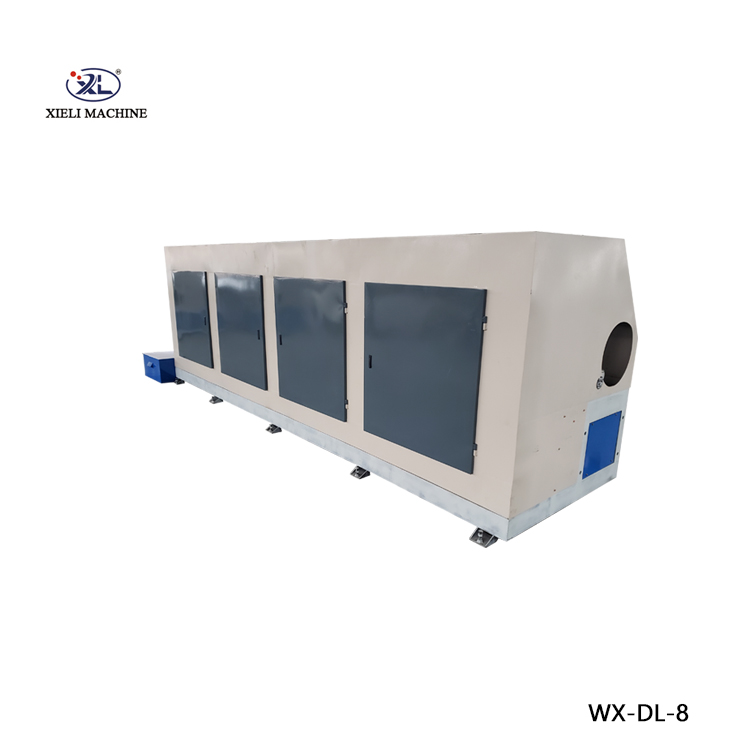

centerless grinder parts

Expertise in centerless grinder parts extends beyond mere familiarity with the components themselves. It encompasses an understanding of the complex interplay between these parts and the overall machine setup. Professionals must be adept at diagnosing issues, predicting wear patterns, and implementing preventive measures to enhance machine efficiency and product quality.

Authoritativeness and trustworthiness in this field stem from hands-on experience and a proven track record of maintaining and operating centerless grinders. Industry leaders and seasoned professionals offer valuable insights and guidelines based on years of practice and continuous learning. Reliable sources and established companies that manufacture and supply centerless grinder parts are instrumental in providing the necessary support and components required to keep the machines running smoothly.

To capitalize on the operational benefits offered by centerless grinders, businesses should invest in high-quality parts and expert operators. This strategic approach not only minimizes downtimes and repair costs but also ensures consistent product quality and maximized productivity. Ultimately, the integrity and success of manufacturing processes hinge on the judicious selection, maintenance, and operation of centerless grinder parts, underscoring the need for a deep well of experience, expertise, authority, and trust in this specialized domain.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.