The Importance of High-Quality Centerless Grinding Machines and Their Pricing

In the realm of manufacturing and metalworking, centerless grinding machines play a crucial role in producing precise cylindrical components. These machines offer a streamlined solution for grinding workpieces without the need for fixtures or additional tooling. As industries seek to enhance productivity while maintaining quality, the demand for high-quality centerless grinding machines has surged. However, potential buyers must navigate a complex landscape of pricing to make an informed decision.

Understanding Centerless Grinding

Centerless grinding is a method that utilizes two wheels the grinding wheel and the regulating wheel. The workpiece is placed between these two wheels, which rotate in opposite directions, allowing for the grinding of the part's outer diameter with precision. This method is particularly effective for producing long runs of cylindrical parts with tight tolerances and excellent surface finishes. Common applications include parts for automotive, aerospace, and medical industries, where precision and reliability are paramount.

Factors Influencing the Price of Centerless Grinding Machines

1. Quality and Brand Reputation The manufacturer's reputation significantly impacts the price. Well-established brands often command higher prices due to their proven reliability, customer support, and innovative technology. High-quality machines tend to offer better performance, longevity, and lower maintenance costs in the long run.

2. Machine Specifications Various specifications affect the cost, including size, wheel diameter, and grinding capacity. Larger machines capable of handling bigger jobs typically come with a higher price tag. Additionally, machines equipped with advanced features such as automatic feed systems, programmable controls, and enhanced safety features will likely be priced higher.

3. Technology Integration The integration of technology, such as CNC (Computer Numerical Control) capability, can significantly influence the cost. CNC centerless grinders offer increased precision and repeatability, reducing the risk of human error and enhancing operational efficiency. These advanced machines are typically priced at a premium.

4. Customization and Features Buyers may require specific modifications or features for their unique applications, which can drive up the cost. Custom machines designed to meet particular processing requirements will entail higher prices due to the additional engineering and manufacturing involved.

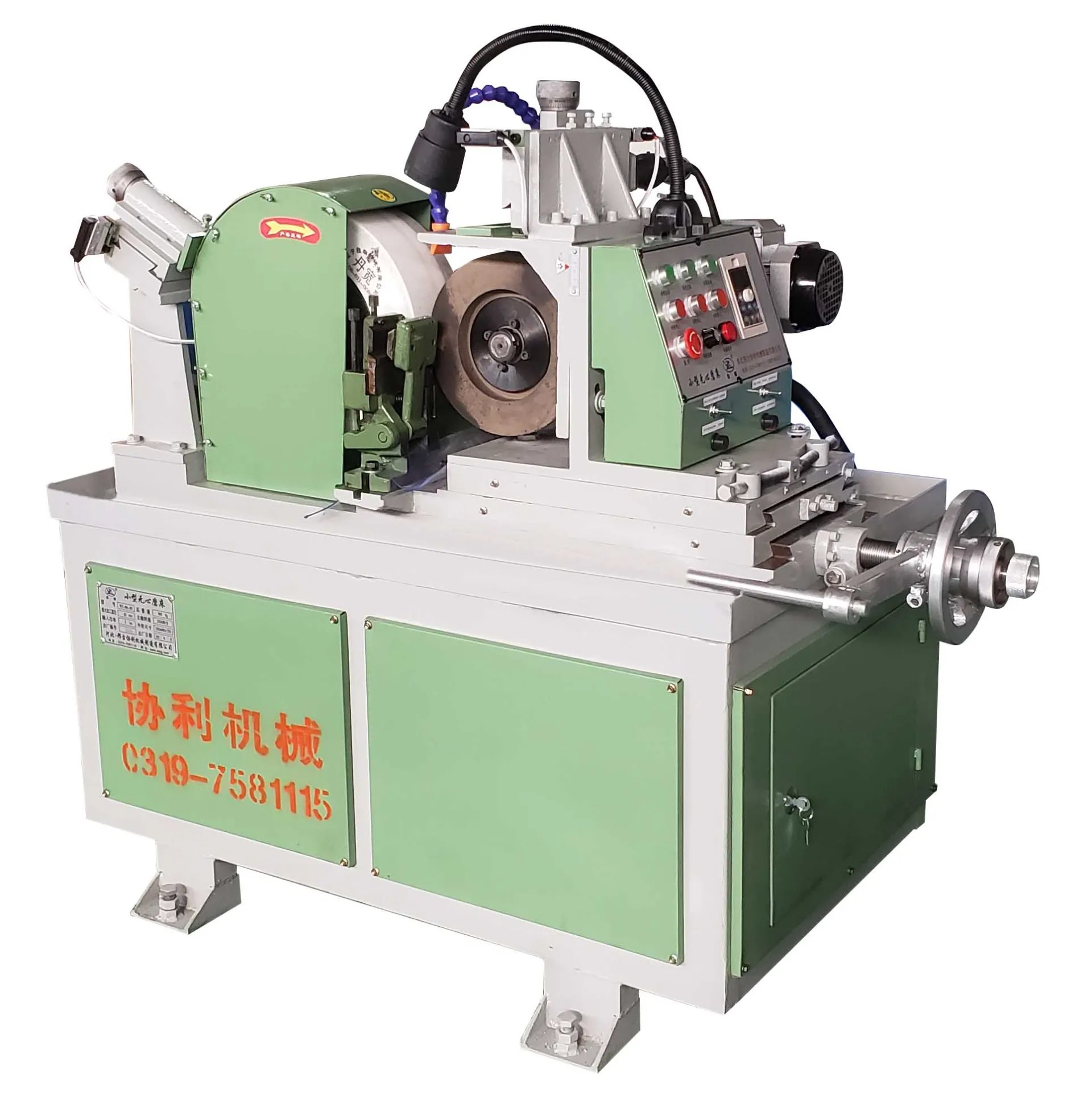

high quality centerless grinding machine price

5. Market Demand Economic factors and market demand can also affect machine pricing. During times of high demand for manufacturing equipment, prices may increase due to competition among buyers. Conversely, in a downturn, prices may stabilize or decrease as manufacturers seek to stimulate sales.

Price Ranges for Centerless Grinding Machines

When seeking high-quality centerless grinding machines, potential buyers can expect a wide range of prices. Entry-level machines may start at around $30,000, targeting small to medium-sized enterprises or those new to centerless grinding. These machines may offer basic features suitable for small-scale operations.

Mid-range machines, often used by established manufacturers, typically fall between $50,000 and $100,000. These units tend to offer better performance, durability, and advanced features, making them suitable for moderate to high-volume production.

High-end, fully CNC-integrated machines can range from $100,000 to over $500,000. These sophisticated systems are designed for high-volume operations and industries that require the utmost precision and consistency in production.

Investing in Quality

Investing in a high-quality centerless grinding machine is a strategic decision for any manufacturing operation. While initial costs may be substantial, the long-term benefits include increased efficiency, reduced waste, and enhanced product quality. As companies strive to remain competitive, the choice of machinery becomes critical.

In conclusion, understanding the dynamics of centerless grinding machine pricing is essential for manufacturers looking to enhance their production capabilities. By evaluating the factors that influence cost and considering the potential return on investment, businesses can make informed decisions that will serve them well into the future. High-quality centerless grinding machines are not just a purchase; they are an investment in precision, efficiency, and quality.