Training for High-Quality Centerless Grinding

Centerless grinding is a specialized machining process that plays a critical role in the production of precision components across various industries. As technological advancements continue to evolve, the demand for high-quality centerless grinding has surged, emphasizing the need for comprehensive training programs. This article explores the importance of effective training for operators and technicians involved in high-quality centerless grinding.

Understanding Centerless Grinding

Centerless grinding is a process that allows for the efficient and accurate grinding of cylindrical workpieces without the need for centering fixtures. This method involves placing the workpiece between two wheels a grinding wheel and a regulating wheel. The grinding wheel performs the material removal, while the regulating wheel controls the workpiece's axial movement. This setup enables continuous production and is ideal for high-volume manufacturing, making it an essential component in industries such as automotive, aerospace, and medical devices.

The Importance of Training

1. Skill Development

To ensure high-quality output in centerless grinding, operators must possess a solid understanding of the machinery, the properties of materials, and the parameters that affect grinding performance. Training programs help in developing these skills, enabling operators to set up and adjust equipment effectively, select appropriate grinding wheels, and understand the impact of parameters such as feed rates and wheel speed on product quality.

Quality control is a pivotal aspect of manufacturing, and centerless grinding is no exception. Operators must be trained in inspection techniques, using tools such as micrometers, calipers, and gages to measure workpiece dimensions accurately. Training programs should also cover the identification and analysis of common defects like out-of-roundness, taper, and surface finish issues. Knowledge of quality standards relevant to specific industries helps ensure that the output meets customer requirements.

3. Safety Awareness

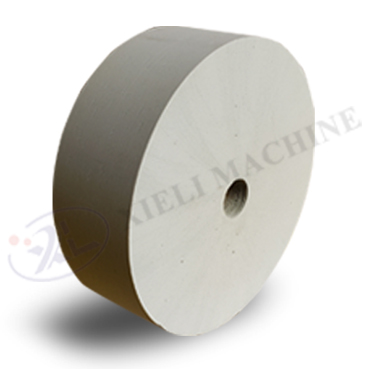

high quality centerless grinder training

Operating centerless grinders involves inherent risks due to moving parts and high-speed operations. Comprehensive safety training is crucial to minimize accidents and ensure a safe working environment. Operators should receive instruction on safety protocols, the proper use of personal protective equipment (PPE), and guidelines for responding to emergencies. Fostering a culture of safety not only protects workers but also contributes to overall operational efficiency.

Components of a High-Quality Training Program

1. Hands-On Experience

Effective training programs incorporate hands-on experience. Trainees should have the opportunity to operate centerless grinding machines under supervision, allowing them to apply theoretical knowledge in a practical setting. This experiential learning reinforces concepts and builds confidence in their skills.

2. Continuous Learning

The field of machining technology is ever-evolving. Organizations should encourage continuous learning and provide resources for ongoing education. This can include workshops, seminars, and access to online training modules that cover new techniques, technologies, and best practices in centerless grinding.

3. Evaluation and Feedback

Continuous evaluation is essential to gauge the effectiveness of the training program. By assessing trainees’ performance and providing constructive feedback, organizations can identify areas for improvement and reinforce successful practices. Regular assessments not only help in skill development but also prepare operators for advanced roles in the manufacturing process.

Conclusion

In summary, a robust training program for high-quality centerless grinding is critical to the success of any production facility. By focusing on skill development, quality control, safety awareness, and continuous learning, organizations can ensure that their operators are well-equipped to meet the demands of modern machining. Investing in training not only enhances product quality and operational efficiency but also fosters a safer workplace, ultimately contributing to the organization’s overall success.