High-Quality Centerless Grinder Tables An Essential Component in Precision Manufacturing

Centerless grinding is a vital process in the manufacturing industry, known for its ability to produce high-precision cylindrical components. At the heart of this process lies the centerless grinder table, which plays a critical role in ensuring the efficiency and accuracy of the grinding operation. High-quality centerless grinder tables are essential for achieving optimal performance and maintaining stringent tolerances in the production of parts.

High-Quality Centerless Grinder Tables An Essential Component in Precision Manufacturing

Additionally, the table must be precisely engineered to facilitate accurate adjustments. This involves the capability to fine-tune the height and angle of the regulating wheel and the grinding wheel. High-quality centerless grinder tables often feature precise adjustment mechanisms that allow operators to easily set and modify these parameters, leading to improved efficiency in production cycles. The better the table design, the more manageable it is to achieve the desired specifications.

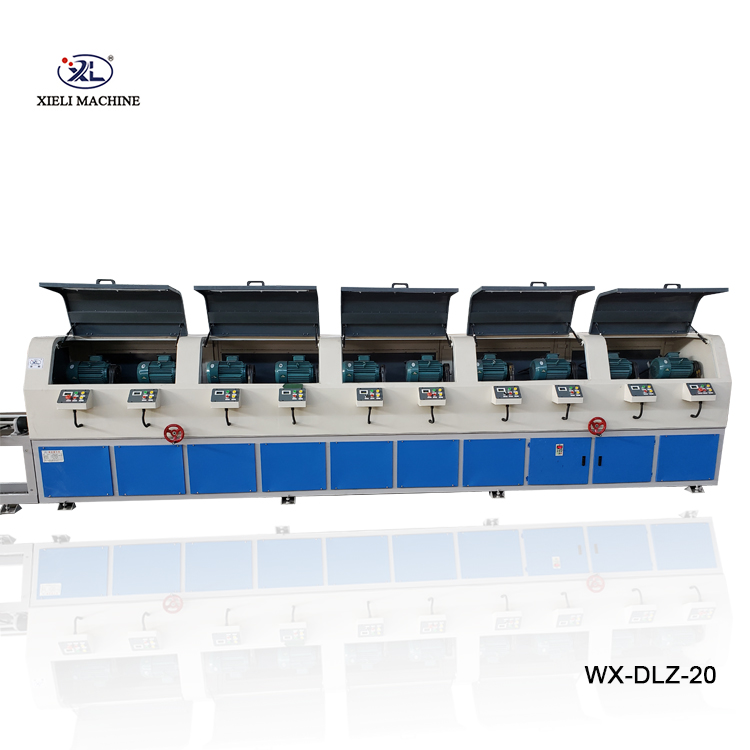

high quality centerless grinder tables

Moreover, a well-designed centerless grinder table will also incorporate advanced features such as vibration dampening systems and thermal stability controls. These features help minimize the influence of external factors that could affect grinding accuracy, ensuring that the machining process remains consistent over time. By reducing vibration and managing heat generated during grinding, these tables contribute to increased tool life and minimized wear on grinding components.

The importance of high-quality centerless grinder tables cannot be overstated, particularly in industries where precision is paramount, such as aerospace, automotive, and medical device manufacturing. In these sectors, even the slightest deviation can lead to significant issues in functionality and safety. Thus, investing in high-quality equipment, including grinder tables, is not just a matter of cost but a critical component of ensuring product integrity.

In conclusion, high-quality centerless grinder tables are indispensable for manufacturers seeking to achieve high precision and efficiency in their grinding processes. Their robust construction, precise adjustability, and advanced features collectively enhance the performance of centerless grinding machines, ensuring that production meets the demanding standards of today’s industries. As the manufacturing landscape continues to evolve, the need for quality components will remain a critical focus for continuous improvement and innovation.