In the ever-evolving industrial landscape, efficiency and precision are paramount. Central to these demands is the multi-head automatic polishing machine, an innovative marvel that has reshaped how industries approach surface finishing tasks. This machine has become indispensable to operations ranging from automotive to aerospace, reflecting both technological sophistication and practical utility.

The brilliance of the multi-head automatic polishing machine lies in its unique design, which incorporates several polishing heads operating simultaneously. This architectural genius allows for substantial surface coverage, reducing the time required for polishing tasks considerably. The seamless operation of multiple heads not only ensures uniformity in finishing but also enhances the capacity to handle large dimensions and complex geometries, which are often challenging for traditional polishing techniques.

One of the most significant advantages of this advanced machinery is its contribution to sustainable manufacturing. Unlike conventional polishing methods that often waste energy and materials, the multi-head automatic polishing machine is engineered for efficiency, optimizing the use of resources while minimizing waste. This increases productivity and aligns with the global push towards greener manufacturing practices, making it a responsible choice for forward-thinking businesses.

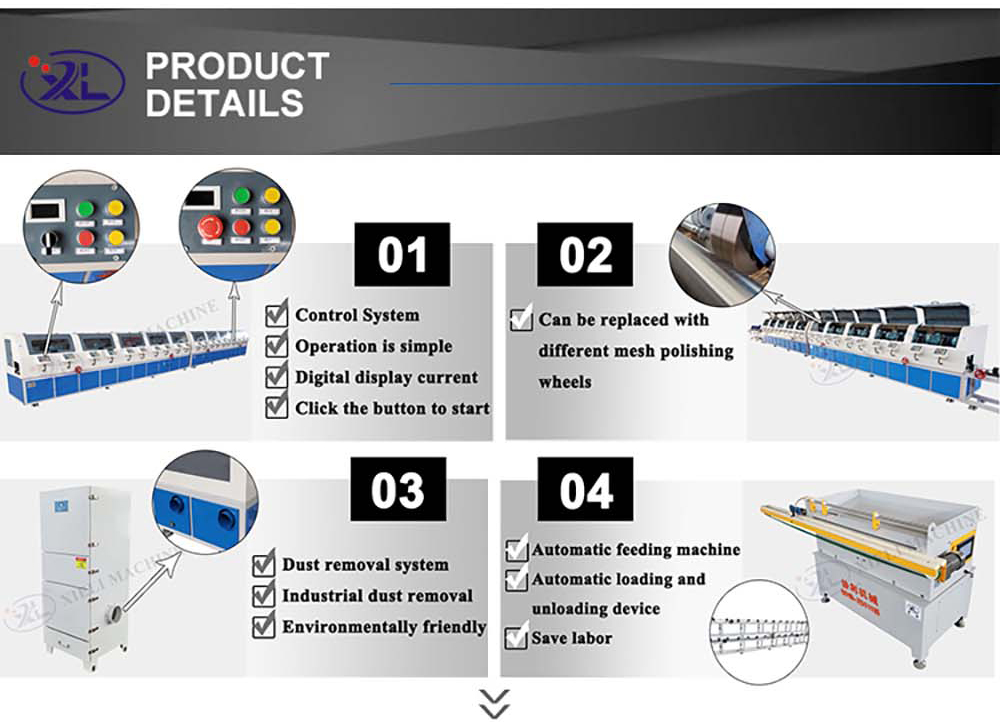

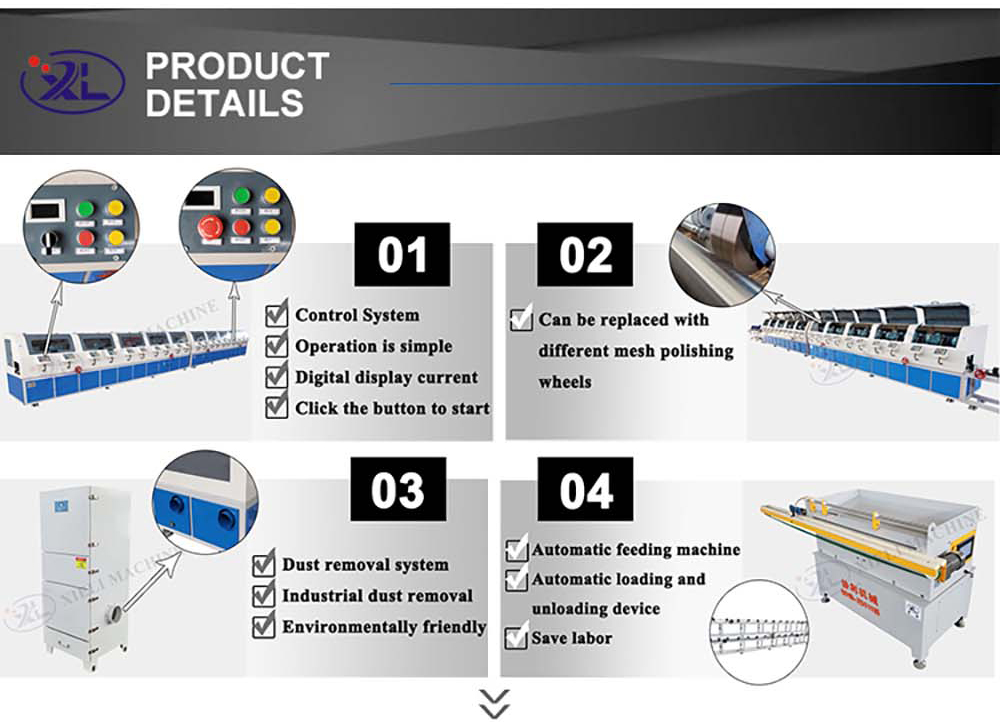

The automation feature of the multi-head polishing machine elevates it to a new echelon of convenience and precision. Through sophisticated computer numerical control (CNC) systems, these machines can be programmed to achieve exact specifications, ensuring consistency across production batches. This automation minimizes human error, reduces labor costs, and boosts output rates, enabling businesses to meet tight deadlines without compromising quality.

Expert users and industry leaders have consistently commended these machines for their adaptability. They are designed to tackle a diverse range of materials, such as metals, plastics, and composite materials. This versatility makes them an ideal choice for manufacturers seeking a single solution to diverse polishing needs. Companies benefit from the operational flexibility that reduces the need for multiple specialized machines, cutting costs and simplifying maintenance logistics.

multi-head automatic polishing machine

The expertise embodied in the design and function of multi-head automatic polishing machines stems from decades of engineering innovation. Leading manufacturers invest significantly in research and development to enhance these machines' capabilities, integrating cutting-edge technologies like IoT sensors and data analytics. These advancements not only improve the machine’s operational efficiency but also provide real-time data on performance and maintenance needs, thereby extending the machine’s lifecycle and reliability.

Trustworthiness and safety are at the core of its esteemed reputation. These machines are built to comply with stringent international safety standards, providing peace of mind to operators around the globe. Equipped with advanced safety features such as emergency stop functions, protective enclosures, and intuitive user interfaces, these machines prioritize operator safety without sacrificing productivity or performance.

The return on investment offered by a multi-head automatic polishing machine is noteworthy. Initial acquisition costs are rapidly offset by reduced labor expenses, fewer material wastages, and increased throughput. The streamlined operation allows businesses to redeploy resources towards other critical areas, driving overall growth and profitability. Consequently, industry experts recognize these machines as a sound investment, especially in sectors where surface finish quality is crucial.

In conclusion, the multi-head automatic polishing machine stands as a testament to engineering prowess and production efficiency. Its role in shaping modern manufacturing processes underscores not just the technological achievements of today but also the potential for future innovations. As industries continue to embrace automation and sustainable practices, the multi-head automatic polishing machine remains at the forefront, championing quality, efficiency, and ecological responsibility.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.