The Rise of MLW Tube Polishing Machine Exporters A Tribute to Precision Engineering

In the realm of industrial manufacturing, tube polishing plays a crucial role in ensuring the aesthetic and functional quality of metal products. Among the leading technologies facilitating this process is the MLW tube polishing machine. Over recent years, MLW tube polishing machine exporters have gained significant attention for their innovative designs and superior performance, making them indispensable assets for companies in various sectors.

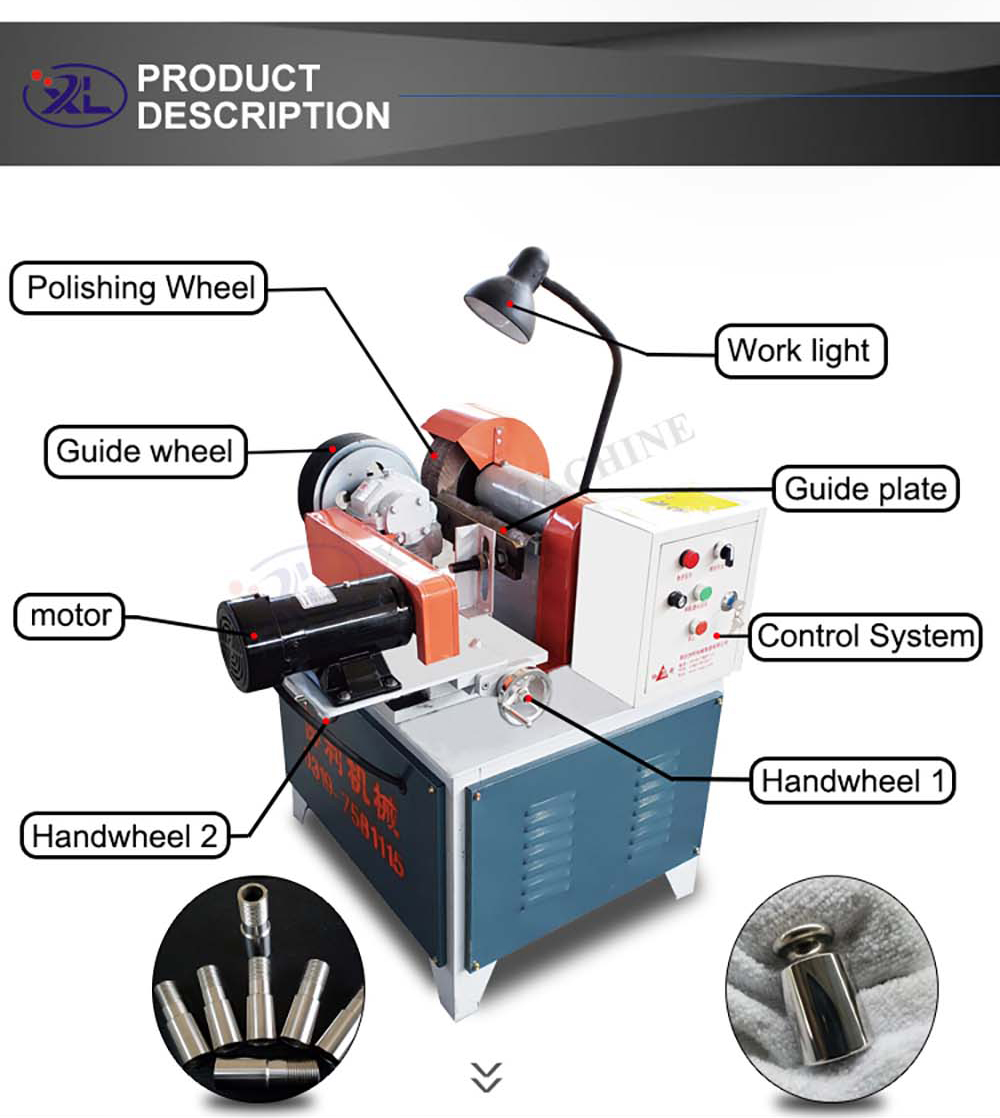

Understanding MLW Tube Polishing Machines

MLW tube polishing machines are engineered to deliver high-quality surface finishes on metal tubes, including stainless steel, aluminum, and other metals. These machines utilize advanced technologies such as abrasive processes, buffing, and electro-polishing to achieve a shiny, smooth finish that not only enhances visual appeal but also improves corrosion resistance. The versatility of MLW machines allows them to be tailored to meet the specific needs of diverse industries, including automotive, aerospace, and furniture manufacturing.

The Export Market for MLW Tube Polishing Machines

With globalization on the rise, the demand for high-quality tube polishing machines has expanded beyond domestic markets. MLW tube polishing machine exporters have seized the opportunity to introduce their products to international customers. By focusing on quality, reliability, and innovation, these exporters have established a strong presence in markets across North America, Europe, and Asia.

One of the factors contributing to the success of MLW tube polishing machine exporters is their commitment to continuous improvement. Manufacturers constantly invest in research and development to incorporate emerging technologies and create machines that offer better performance, efficiency, and ease of use. This dedication ensures that their products not only meet but exceed the expectations of users across various sectors.

Challenges Faced by Exporters

mlw100 tube polishing machine exporters

Despite the promising growth prospects, MLW tube polishing machine exporters face several challenges. One such challenge is the increasing competition from both domestic and international manufacturers. As other companies develop similar machines, maintaining a competitive edge becomes crucial. Exporters must emphasize their unique selling propositions, such as superior quality, customer service, and customized solutions, to differentiate themselves in a crowded market.

Another challenge is navigating the complexities of international trade regulations. Exporters must stay informed about the requirements for different countries, including safety standards, certifications, and tariffs. This can be a daunting task, as non-compliance can lead to financial losses and damage to a company's reputation.

The Future of MLW Tube Polishing Machine Exporters

Looking ahead, the future of MLW tube polishing machine exporters appears bright, driven by advances in technology and an increasing global demand for high-quality metal finishes. As industries continue to evolve, the need for efficient and reliable polishing solutions will become even more pronounced. This opens up new opportunities for exporters to introduce innovative products and tap into emerging markets.

Furthermore, sustainability is expected to play an increasingly important role in manufacturing processes. MLW tube polishing machine exporters can lead the charge by developing environmentally friendly solutions that minimize waste and energy consumption. By aligning their products with sustainability goals, exporters can enhance their appeal to eco-conscious customers and boost their market presence.

Conclusion

The landscape of tube polishing machines is rapidly evolving, with MLW tube polishing machine exporters at the forefront of this transformation. Their dedication to quality, innovation, and customer satisfaction positions them for continued success in the global market. As they adapt to challenges and capitalize on new opportunities, these exporters will play a pivotal role in shaping the future of precision engineering and manufacturing worldwide.