The Benefits of Centerless Grinder Machines A Comprehensive Overview

In the modern manufacturing landscape, precision and efficiency have become paramount. Among the variety of machinery available, centerless grinder machines stand out for their ability to produce high-quality components with minimal human intervention. These machines are essential for industries that require tight tolerances and intricate finishes, making them a sought-after solution for factories around the world.

What is a Centerless Grinder Machine?

A centerless grinder machine operates by grinding the exterior surfaces of cylindrical workpieces without the need for a supporting center. Unlike traditional grinding, which requires the workpiece to be suspended between centers, centerless grinding utilizes a combination of a grinding wheel, a regulating wheel, and a workrest blade to hold and control the workpiece. This method allows for continuous feeding of parts, significantly improving production rates while maintaining precision.

Key Features and Advantages

1. High Efficiency Centerless grinders are designed for high-volume production. They allow for the processing of multiple workpieces simultaneously, reducing downtime and maximizing productivity. Factories benefit from increased output without compromising quality, making these machines ideal for mass production scenarios.

2. Versatile Applications Centerless grinding is versatile, capable of handling a wide range of materials including steel, aluminum, and plastics. This flexibility makes them applicable in various industries such as automotive, aerospace, and medical equipment manufacturing, where different materials and precise dimensions are often required.

3. Precision and Consistency The design of centerless grinders enables them to achieve very tight tolerances, often as low as ±0.0001 inches. This level of precision is critical in industries where components must fit together perfectly to ensure functionality, such as in engine parts or assembly fitting.

4. Reduced Setup Time Unlike traditional grinders, centerless grinders often require less setup time. Their design allows for quicker adjustments and changeovers, which is a significant advantage in environments where production runs frequently change from one component to another.

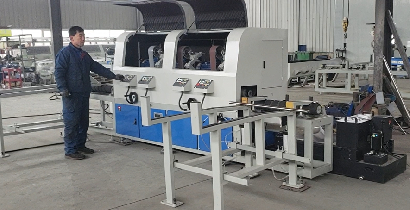

centerless grinder machine for sale factories

5. Lower Labor Costs Automating the grinding process with a centerless grinder reduces the reliance on manual labor, thus lowering overall labor costs. The machine can operate with minimal supervision, allowing factory workers to focus on other essential tasks.

Considerations for Purchase

When looking to purchase centerless grinder machines, factories should consider several factors

- Type and Size The specific requirements of the manufacturing process will influence the type and size of the centerless grinder selected. It's essential to choose a machine that aligns with both the size of the workpieces and the volume of production.

- Brand Reputation and Service Opting for well-known brands can assure reliability and quality. It's also vital to consider after-sales service and support, including availability of spare parts and maintenance services.

- Cost Efficiency While initial investment costs can be significant, the long-term savings in efficiency and labor can justify this expenditure. Factories should conduct a cost-benefit analysis to determine the best fit for their production goals.

Conclusion

Centerless grinder machines represent a valuable asset for factories aiming to enhance their manufacturing capabilities. With their numerous benefits—including high efficiency, versatility, and precision—they not only improve the production process but also contribute to the overall quality of the end products. As industries continue to evolve, investing in advanced machinery like centerless grinders will be crucial for maintaining competitive advantages and meeting the ever-increasing demands of the market. With the right selection and maintenance, these machines can serve factories reliably for years to come.