The Importance of High-Quality Centerless Grinder Blades for Precision Manufacturing

In the world of precision manufacturing, the role of centerless grinders cannot be overstated. Centerless grinding is a widely used method for machining parts, primarily due to its efficiency and ability to produce workpieces with tight tolerances. At the heart of this process lies the quality of the blades used in the centerless grinding machines. Thus, choosing the right centerless grinder blades manufacturer is crucial for ensuring the optimal performance of these machines.

Understanding Centerless Grinding

Centerless grinding differs from traditional grinding methods in that it does not use a spindle to hold the workpiece. Instead, the workpiece is placed between two wheels the grinding wheel and the regulating wheel. The grinding wheel removes material from the workpiece, while the regulating wheel controls the rotational speed and movement of the workpiece. This technique allows for high-speed production and can accommodate long lengths of workpieces, making it ideal for producing cylindrical parts such as shafts, rods, and tubes.

The Role of Blades in Centerless Grinding

The blades used in centerless grinding machines must meet specific standards to ensure effective performance and durability. High-quality blades are essential for achieving the desired surface finish and dimensional accuracy. Blades that are well-manufactured will resist wear and tear, allowing manufacturers to maintain high levels of precision without frequent replacements.

When selecting centerless grinder blades, factors such as material composition, blade geometry, and coating must be considered. Manufacturers often use high-speed steel or carbide for blades due to their hardness and wear resistance. Additionally, the design of the blade, including its angles and profiles, can significantly influence the grinding process’s outcome. Choosing a manufacturer that understands these intricacies is vital for optimizing the grinding operation.

Choosing the Right Manufacturer

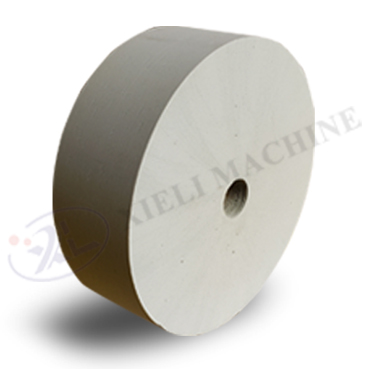

centerless grinder blades manufacturer product

When seeking a centerless grinder blades manufacturer, businesses should prioritize quality, experience, and customer support. Established manufacturers with a proven track record tend to provide products that meet industry standards. It’s essential to look for companies that invest in research and development to innovate and improve their products continuously.

Moreover, a good manufacturer will offer customization options. Different applications and materials may require tailored blade designs, and a responsive manufacturer should be able to accommodate specific needs. This flexibility not only enhances the grinding process but also contributes to overall production efficiency.

Benefits of High-Quality Centerless Grinder Blades

Investing in high-quality centerless grinder blades brings numerous advantages. First and foremost, it ensures consistent performance and reliability. Blades that are designed to withstand the rigors of grinding reduce downtime due to maintenance and replacement, ultimately leading to improved productivity.

Furthermore, superior blades can enhance the quality of the finished product. They allow for finer surface finishes and better dimensional accuracy, which is critical in industries such as aerospace, automotive, and medical manufacturing, where precision is paramount.

Lastly, choosing a reputable centerless grinder blades manufacturer often comes with additional benefits such as warranty options and after-sales support. Manufacturers that stand behind their products are more likely to provide assistance in case of technical issues or performance concerns.

Conclusion

In conclusion, the choice of centerless grinder blades manufacturer is a significant factor in the success of precision manufacturing operations. With the right blades, companies can enhance their production capabilities, improve product quality, and achieve greater efficiency. As the demands for precision and quality continue to rise in various industries, investing in high-quality centerless grinder blades has become more critical than ever.