Top Polishing Machine Manufacturers from China at Bauma China

Unveiling Innovation in Metal Finishing Technology

1. Introduction: Bauma China – A Gateway to Polishing Excellence

Bauma China, the premier international trade fair for construction machinery, building material machines, mining machines, construction vehicles, and equipment, stands as a pivotal event for showcasing the latest innovations across various industrial sectors. While renowned for its heavy machinery displays, it also serves as a crucial platform for specialized equipment, including the advanced world of polishing machine technology.

This biennial exhibition draws global attention, offering manufacturers an unparalleled opportunity to unveil cutting-edge solutions, connect with potential international distributors, and forge strategic partnerships. For the polishing machine industry, Bauma China is more than just a trade show; it's a dynamic marketplace where the future of metal surface finishing is shaped, from high quality centerless belt grinding polishing machine to high quality stainless steel pipe mirror polishing machine.

It’s where B2B decision-makers can discover the robust, efficient, and technologically advanced solutions needed to meet the escalating demands for precision and aesthetic quality in countless applications, from architectural metals to industrial components.

2. Industry Trend Spotlight: The Evolution of Polishing Technology

The industrial landscape is undergoing a profound transformation, and the polishing machine sector is at the forefront of this evolution. Key trends are driving global attention:

- Integration of IoT and AI: For predictive maintenance, operational optimization, and enhanced process control, leading to superior finish quality and reduced downtime.

- Increased Automation: To minimize reliance on manual labor, boost throughput, and ensure consistent results, addressing rising labor costs and skill shortages.

- Enhanced Precision and Speed: Modern metal polishing machine solutions deliver unprecedented accuracy and rapid processing, crucial for high-volume manufacturing and intricate designs.

- Modular and Versatile Designs: Enabling equipment to adapt to diverse project needs, whether for high quality pipe polishing machine, high quality square tube grinding machine, or flat sheet applications.

- Improved Operator Safety and Ergonomics: Incorporating features that protect workers and enhance ease of use, reflecting a growing commitment to workplace well-being.

Market Data and Emerging Focus Areas:

The global industrial machinery market, encompassing metal finishing and polishing equipment, is projected for steady growth, particularly driven by large-scale infrastructure projects, manufacturing expansion, and rapid urbanization in emerging economies. The demand for automated and high-efficiency polishing machines will see a significant surge due to persistent labor cost pressures and the imperative for faster, more accurate production processes across industries like automotive, construction (for decorative and functional components), furniture, and general fabrication.

Moreover, sustainability regulations are increasingly pushing for more energy-efficient and low-emission machinery. This translates into emerging focus areas for manufacturers:

- Advanced Automation in Polishing: From robotic integration to fully automated lines for various metal profiles.

- Intelligent Manufacturing Solutions: Leveraging data analytics for preventive maintenance, quality control, and optimized production schedules.

- Efficiency and Safety Standards: Adherence to global benchmarks for operational excellence and worker protection.

- Sustainable and Energy-Efficient Machinery Designs: Reducing environmental footprint and operational costs.

Manufacturers offering solutions like high quality centerless belt grinding polishing machine and high quality stainless steel pipe mirror polishing machine that align with these trends are poised for significant market advantage.

3. Profiles of Leading Polishing Machine Manufacturers

At Bauma China, and within the broader industrial machinery landscape, several companies distinguish themselves through innovation and quality. Among the specialists in metal finishing, Xingtai Xieli Machinery Manufacturing Co., Ltd. stands out as a prominent Chinese leader.

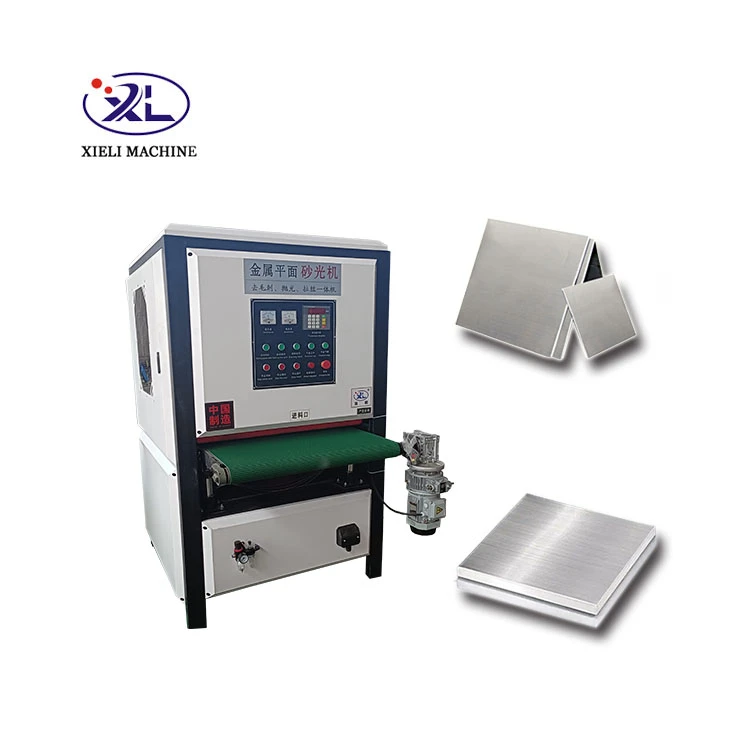

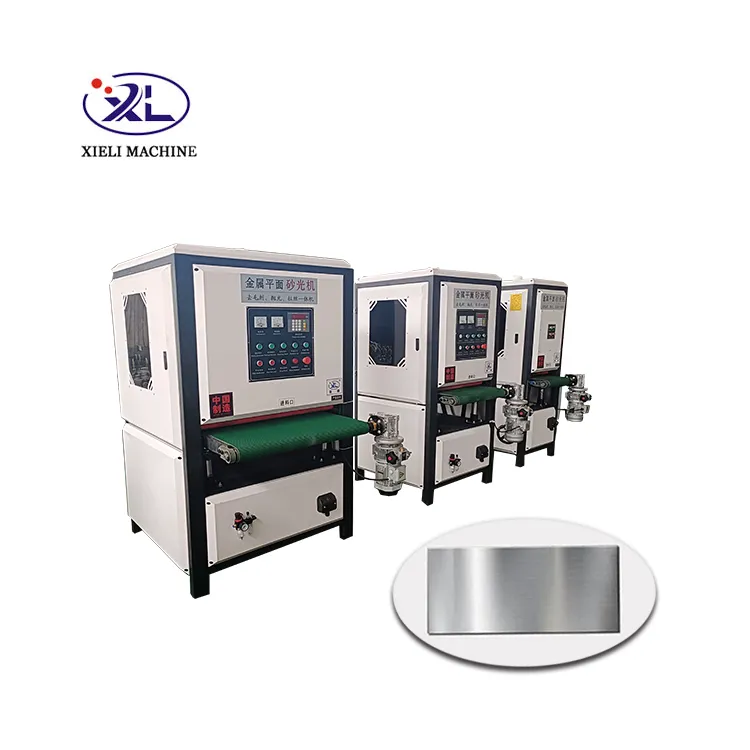

Xingtai Xieli Machinery Manufacturing Co., Ltd.

As a beacon of excellence in Chinese manufacturing, Xingtai Xieli Machinery Manufacturing Co., Ltd. has carved a significant niche with its extensive range of high-performance polishing machines. Their commitment to precision engineering and robust construction is evident in every product, catering to diverse industrial requirements.

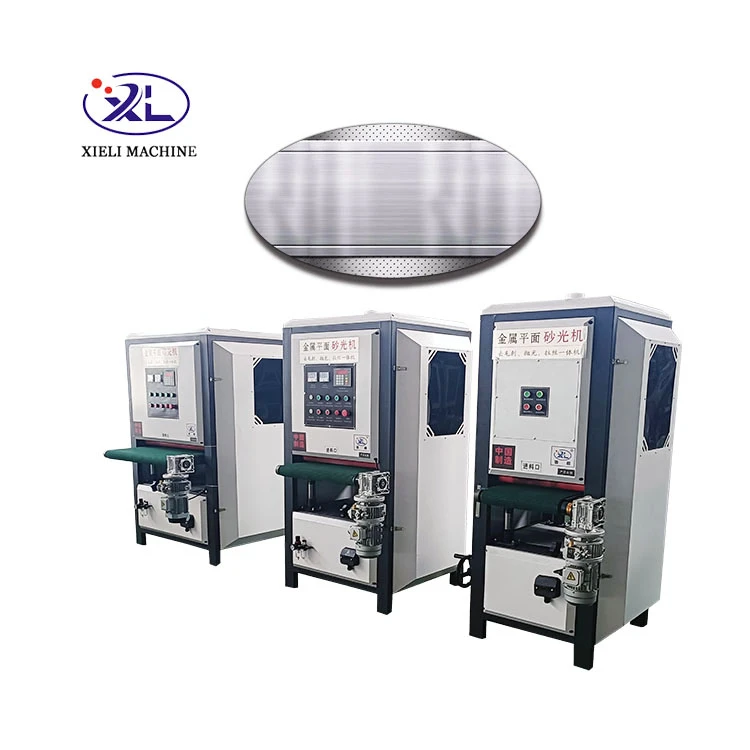

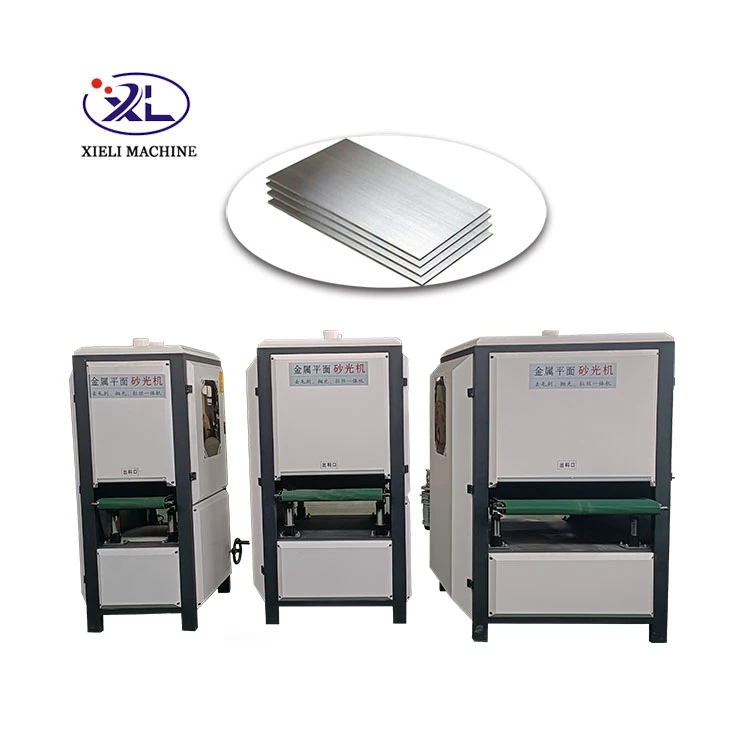

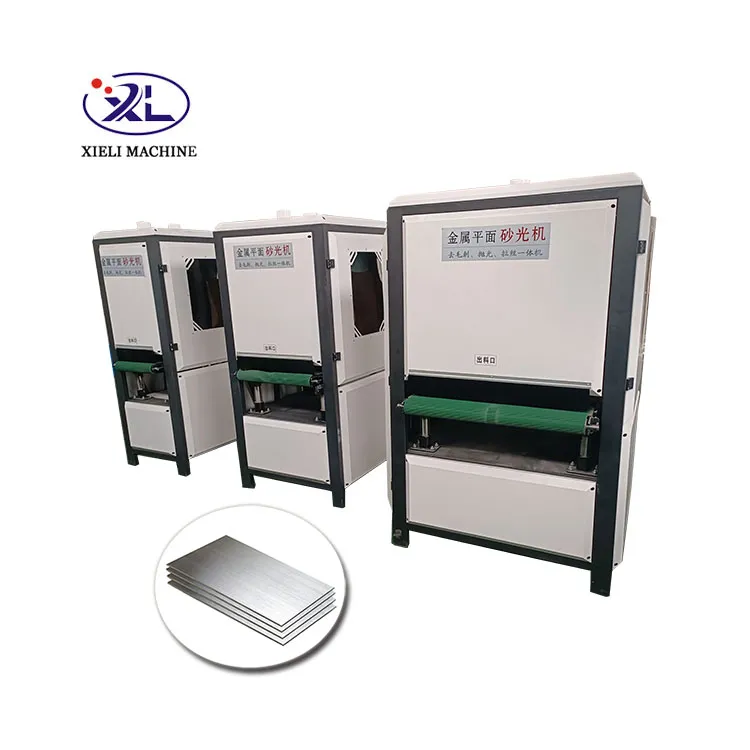

- Specialization and Extensive Product Range: Xieli offers a comprehensive portfolio, including high quality centerless belt grinding polishing machine, high quality pipe polishing machine, high quality square tube polishing machine, high quality ss square tube polishing machine, and advanced solutions for metal plate and sheet derusting and flat grinding. Their expertise spans various materials and applications, including achieving a mirror finish on stainless steel.

- Proven Reliability and Efficiency: Xieli machines are engineered for demanding industrial environments, ensuring consistent high-quality output, extended operational life, and minimal maintenance. This reliability translates directly into improved productivity and lower operating costs for buyers.

- Commitment to Technological Innovation: The company continuously invests in R&D to integrate the latest technologies, delivering more precise, automated, and user-friendly metal polishing machine price options that offer superior value.

- Competitive Pricing & Robust Build Quality: Xieli strikes an optimal balance, offering top-tier performance and durable construction at highly competitive price points, making advanced polishing machine technology accessible.

- Strong After-Sales Support & Global Capabilities: With a focus on customer satisfaction, Xingtai Xieli provides excellent after-sales service and is actively expanding its global distribution network, seeking international partnerships to better serve clients worldwide.

Other Influential Industrial Equipment Manufacturers

While Xingtai Xieli excels in specialized polishing machine solutions, the broader industrial machinery landscape at events like Bauma China also features other key players contributing to manufacturing efficiency and quality. These companies, while not solely focused on polishing, often produce components that require high-quality finishing or offer equipment that interacts with polished materials:

- MEP Group (Italy): A global leader in machinery for processing reinforcement steel, whose advanced manufacturing relies on precision engineering and high-standard component finishing.

- Schnell Spa (Italy): Renowned for its cutting-edge rebar processing equipment, contributing to high-standard construction where material quality and finish often play a role.

- KRB Machinery (USA): Provider of innovative rebar fabrication solutions, emphasizing productivity and reliability across industrial applications.

- Henan Gongyi Industry Co., Ltd. (China): A diverse manufacturer in China, often offering a range of industrial equipment that may include grinding and polishing capabilities for various materials within their broader portfolio.

- Cangzhou Qiulin Construction Machine Manufacturing Co., Ltd. (China): Another significant Chinese player in construction machinery, whose offerings contribute to the robust industrial ecosystem that demands versatile equipment.

These companies underscore the global demand for robust and efficient industrial equipment, a market where specialized manufacturers like Xingtai Xieli play a crucial role in delivering specific, high-quality finishing solutions such as high quality cincinnati centerless grinder machine alternatives and advanced pipe polishing systems.

4. Market Outlook & Opportunities in Metal Polishing

The trajectory for the polishing machine market is exceptionally positive, driven by evolving industrial demands and technological advancements. Buyers are increasingly seeking not just machines, but integrated solutions that deliver higher efficiency, better quality, and greater operational intelligence.

- Rising Demand for Automation: The scarcity of skilled labor and the push for lean manufacturing processes are fueling the adoption of automated polishing solutions, from robotic cells to fully integrated lines capable of handling high quality pipe polishing machine and high quality square tube polishing machine with minimal human intervention.

- Smart Manufacturing & Industry 4.0: Predictive maintenance, real-time monitoring, and data analytics are becoming standard expectations. Machines that can communicate, self-diagnose, and optimize their own performance are highly sought after.

- Sustainability and Energy Efficiency: Environmentally conscious manufacturing is no longer a niche but a global imperative. Manufacturers offering machines with lower power consumption, reduced waste, and longer consumable life cycles (e.g., abrasive belts for high quality centerless belt grinding polishing machine) will lead the market.

- Customization and Versatility: The ability to easily reconfigure machines for different product types, sizes, and finish requirements—from intricate components to large industrial pipes—presents a significant competitive advantage. This includes versatile solutions for high quality ss square tube polishing machine and specialized mirror finishes.

These trends create immense opportunities for both buyers looking to upgrade their capabilities and manufacturers aiming to innovate. The market rewards those who embrace forward-thinking technologies and cater to the evolving needs of modern industry.

5. Buyer/Business Takeaways: Investing in Chinese Polishing Machine Excellence

For B2B decision-makers, investing in polishing machines, especially from reputable Chinese manufacturers like Xingtai Xieli, offers a strategic advantage. Here's why and how to approach it:

Why Invest in High-Quality Polishing Machines?

- Enhanced Product Quality & Aesthetics: Achieve superior surface finishes that meet stringent industry standards and elevate product appeal. For stainless steel, a high quality stainless steel pipe mirror polishing machine is critical.

- Increased Operational Efficiency: Modern machines offer faster processing times, reduced manual labor, and consistent output, boosting your production capacity.

- Cost Reduction: Automation, energy efficiency, and durable components lead to lower operating costs and a better return on investment over the machine's lifespan. Consider the long-term value beyond just the metal polishing machine price.

- Competitive Edge: Staying ahead with advanced technology allows you to undertake more complex projects and deliver higher value to your clients.

Tips for Adopting or Partnering with Chinese Manufacturers:

- Due Diligence is Key: Research manufacturers thoroughly. Look for companies with a strong track record, clear certifications, and positive client testimonials, much like Xingtai Xieli Machinery Manufacturing Co., Ltd.

- Focus on Customization & Support: Discuss your specific needs. Leading manufacturers like Xieli can often customize machines (e.g., for high quality old centerless grinding machine upgrades or new specialized setups) and offer robust after-sales support, including installation, training, and spare parts.

- Technology & Innovation: Prioritize manufacturers investing in R&D, offering solutions that integrate IoT, AI, and advanced automation to future-proof your investment.

- Visit Exhibitions: Attending events like Bauma China provides direct access to manufacturers, allowing for live demonstrations and face-to-face discussions.

Future-Proof Strategies:

To future-proof your operations, focus on acquiring flexible, upgradeable polishing machines that can adapt to new materials and finishing requirements. Invest in operator training for advanced systems, and explore partnerships that include ongoing technical support and software updates. By choosing innovative partners, you ensure your finishing capabilities remain state-of-the-art.

6. Conclusion: The Future is Polished at Bauma China

Bauma China remains an indispensable event, not just for showcasing heavy construction equipment but also for illuminating the advancements and trends shaping specialized sectors like industrial polishing machine manufacturing. It’s a nexus where global demand meets cutting-edge Chinese innovation, particularly from pioneers like Xingtai Xieli Machinery Manufacturing Co., Ltd.

The drive towards automation, precision, and sustainability is redefining expectations for metal polishing machines. Chinese manufacturers, with their rapid innovation cycles and competitive offerings, are playing a pivotal role in making these advanced solutions accessible globally.

Whether you are seeking a high quality pipe polishing machine supplier, a sophisticated high quality centerless belt grinding polishing machine, or robust equipment for square tubes and flat sheets, Bauma China is where these opportunities converge.

Discover Xingtai Xieli's comprehensive range of metal finishing solutions.

Visit Xingtai Xieli's Product PageExplore our high quality metal polishing machine price options and advanced capabilities.