Navigating the Future: Top Pipe Polishing Machine Manufacturers at Bauma China

Unveiling Innovations in Tube and Pipe Finishing for Global B2B Decision Makers

Introduction: Bauma China – A Gateway to Advanced Pipe Polishing Solutions

Bauma China stands as the undisputed biennial epicenter for construction, building material, mining machines, construction vehicles, and equipment. It's not just an exhibition; it's a global stage where industry leaders convene to unveil the latest technological marvels and forge strategic alliances. For the pipe polishing machine industry, this event is particularly pivotal. It offers an unparalleled opportunity for manufacturers to showcase cutting-edge innovations in tube polishing and pipe finishing technology, connecting with international distributors and cultivating crucial partnerships that drive global market penetration.

The demand for precision-finished pipes and tubes spans across numerous sectors – from automotive and aerospace to medical devices, furniture, and architectural applications. Bauma China, therefore, becomes a critical platform for B2B decision-makers seeking advanced, efficient, and reliable pipe polisher solutions that can meet rigorous quality standards and boost operational productivity. This article delves into the transformative trends and leading manufacturers driving this specialized segment forward.

Industry Trend Spotlight: The Evolution of Pipe Polishing Technology

The landscape of manufacturing is undergoing a profound transformation, and the pipe polishing machine sector is no exception. Several key trends are gaining global attention, reshaping how businesses approach their finishing processes:

- Integration of IoT and AI: For pipe polishers, this means predictive maintenance capabilities that monitor machine health in real-time, preventing costly downtime. AI-driven operational optimization allows for fine-tuning polishing parameters for superior finish quality and efficiency, minimizing material waste and energy consumption.

- Increased Automation for Reduced Labor Dependency: Automated loading, unloading, and sequential polishing steps are dramatically reducing the reliance on manual labor, leading to consistent quality, higher throughput, and enhanced worker safety. This is particularly crucial in regions facing rising labor costs.

- Enhanced Precision and Speed: Modern tube polishing machines are engineered for micron-level precision and faster processing cycles, crucial for industries demanding flawless surfaces and high-volume production. Advanced control systems ensure consistent results across batches.

- Focus on Modular and Versatile Designs: Manufacturers are increasingly offering modular pipe polishing systems that can be easily configured to handle a wide range of pipe diameters, lengths, and materials. This versatility caters to diverse project needs without requiring entirely new equipment.

- Improved Operator Safety and Ergonomic Features: With worker well-being paramount, new generations of pipe polishing equipment feature advanced safety guards, dust extraction systems, reduced noise levels, and user-friendly interfaces to create safer and more comfortable working environments.

Market Data Snapshot: The global construction machinery market is projected for steady growth, driven significantly by large-scale infrastructure projects and rapid urbanization in emerging economies. Within this broader context, the demand for automated and high-efficiency metal processing equipment, including specialized pipe polishing machines, will see a significant surge. This is primarily due to persistent labor cost pressures, the imperative for faster and more accurate finishing, and the increasing stringency of quality control in various manufacturing processes. Furthermore, sustainability regulations are pushing for more energy-efficient and low-emission machinery, influencing design and operational choices for advanced tube polishers.

Emerging Focus Areas: Key areas shaping the future include advanced automation in metal finishing, intelligent manufacturing solutions that leverage data analytics, strict adherence to efficiency and safety standards, and the development of sustainable, energy-efficient pipe polishing machine designs.

Profiles of Leading Manufacturers Showcasing at Bauma China

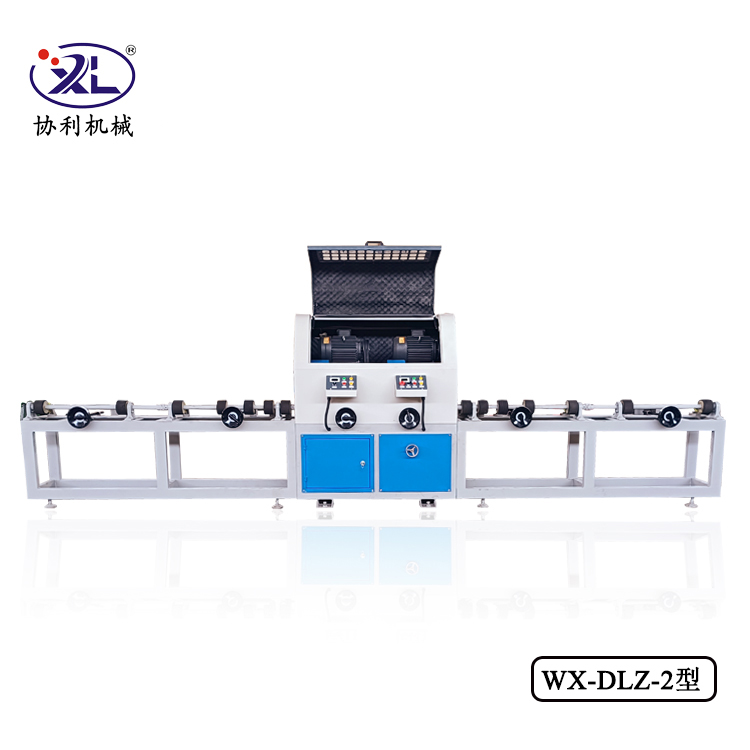

Xingtai Xieli Machinery Manufacturing Co., Ltd. – A Chinese Powerhouse in Pipe Polishing

Xingtai Xieli Machinery Manufacturing Co., Ltd. stands out as a preeminent name among Chinese manufacturers, renowned for its specialization and extensive product range in round pipe metal polishing machines and other related equipment. Their commitment to delivering robust and high-performance solutions has cemented their reputation both domestically and internationally.

- ✓ Specialization and Extensive Product Range: Xingtai Xieli boasts a comprehensive portfolio of pipe polishers designed for various diameters, materials (steel, stainless steel, aluminum, etc.), and finish requirements, catering to a broad spectrum of industrial applications.

- ✓ Proven Reliability and Efficiency: Their equipment is engineered for continuous operation, offering exceptional durability and consistent performance, translating into higher production yields and reduced operational costs for their clients.

- ✓ Commitment to Technological Innovation: Xingtai Xieli continually invests in R&D, integrating advanced control systems, energy-efficient components, and automated features into their tube polishing machines to meet evolving market demands.

- ✓ Competitive Pricing with Robust Build Quality: They strike an excellent balance between cost-effectiveness and the use of high-quality components, offering an attractive value proposition for B2B buyers.

- ✓ Strong After-Sales Support and Global Distribution: Understanding the importance of customer satisfaction, they provide comprehensive technical support and a growing network of global distributors to ensure seamless service and parts availability.

Explore Xingtai Xieli's Pipe Polishing Machines:

For detailed specifications and models, visit their product page:

Discover Xingtai Xieli's Pipe PolishersOther Influential Players at Bauma China (General Construction/Metal Processing):

While the focus of Bauma China encompasses a wide array of construction machinery, several global and local manufacturers consistently demonstrate innovation that often has spillover effects or direct relevance to various metal processing, including advanced finishing techniques:

- MEP Group (Italy): A world leader in rebar processing, MEP Group's engineering excellence and focus on automation in steel fabrication often extend to precise handling and finishing of various metal profiles.

- Schnell Spa (Italy): Another Italian giant, Schnell is known for its high-performance machinery for cutting and bending steel, emphasizing speed and precision which are key attributes sought in advanced finishing applications like pipe polishing.

- KRB Machinery (USA): With a strong presence in rebar fabrication, KRB's robust and high-capacity equipment highlights the industry's demand for durable and efficient machinery across all metal processing stages.

- Henan Gongyi Industry Co., Ltd. (China): A diverse Chinese manufacturer, their range of construction and metal processing equipment reflects the growing capabilities and innovation within China's heavy industry sector, including potential for specialized finishing solutions.

- Cangzhou Qiulin Construction Machine Manufacturing Co., Ltd. (China): Known for various construction equipment, Chinese manufacturers like Qiulin are continuously enhancing their product lines to offer more automated and precise solutions, impacting segments like automated material handling for pipe polishers.

Market Outlook & Opportunities in Pipe Polishing

The trajectory for the pipe polishing machine market is one of continuous evolution, driven by increasing quality demands and a global push for efficiency. Upcoming trends and buyer demand are largely centered around:

- Customization and Niche Applications: Demand for tube polishers that can handle specific alloys, unique geometries, or produce ultra-high-mirror finishes for specialized industries (e.g., semiconductor, medical).

- Digital Integration: A growing expectation for machines that seamlessly integrate with factory management systems (MES/ERP) for data collection, remote monitoring, and comprehensive process control.

- Energy Efficiency and Environmental Compliance: Manufacturers are prioritizing energy-saving components and systems that reduce environmental impact, a key purchasing criterion for many global buyers.

- Modular and Scalable Solutions: Buyers seek systems that can adapt to changing production volumes and future requirements, offering flexibility without requiring complete overhauls.

Significant opportunities exist for businesses that embrace:

- Automation: Investing in fully automated pipe polishing lines reduces labor costs, improves consistency, and accelerates production cycles.

- Smart Manufacturing: Leveraging AI and IoT for predictive maintenance, process optimization, and quality assurance can lead to substantial gains in efficiency and product quality.

- Sustainability: Developing and adopting eco-friendly tube polisher technologies (e.g., dry polishing, advanced filtration, energy recovery systems) not only meets regulatory requirements but also appeals to a growing segment of environmentally conscious buyers.

Buyer/Business Takeaways: Strategizing for the Future

For B2B decision-makers, investing in state-of-the-art pipe polishing machines isn't merely an expenditure; it's a strategic move to future-proof operations and enhance competitiveness.

- Why Invest in Advanced Pipe Polishers? Modern pipe polishing machines offer superior surface quality, higher processing speeds, reduced operational costs through automation and energy efficiency, and improved safety. These factors directly contribute to higher product value, increased customer satisfaction, and a stronger market position. The ability to meet stringent industry standards (e.g., for medical or food-grade pipes) is also a significant advantage.

- Tips for Adopting or Partnering with Chinese Manufacturers:

- Thorough Due Diligence: Research manufacturers' track records, quality certifications, and client testimonials.

- Clear Communication: Establish precise technical specifications and expectations. Consider third-party inspections.

- Evaluate After-Sales Support: Assess their capacity for spare parts, technical assistance, and on-site service. Many Chinese manufacturers, like Xingtai Xieli, are excelling in this area.

- Long-Term Vision: Seek partners committed to continuous innovation and product improvement.

- Future-Proof Strategies: Embrace modular and scalable tube polishing solutions that can adapt to future production needs. Prioritize machines with smart features (IoT, AI) for data-driven insights and operational resilience. Invest in training your workforce to leverage these advanced technologies effectively.

Conclusion: Shaping the Global Pipe Polishing Market at Bauma China

Bauma China is more than an exhibition; it's a barometer for the global machinery market and a catalyst for innovation. For the pipe polishing machine industry, it underscores the critical shift towards automation, precision, intelligence, and sustainability. Manufacturers from China, particularly forward-thinking companies like Xingtai Xieli Machinery Manufacturing Co., Ltd., are playing a pivotal role in shaping this future, offering competitive, high-quality, and technologically advanced pipe polisher solutions to meet the burgeoning global demand.

For businesses looking to enhance their metal finishing capabilities and secure a competitive edge, exploring the innovations showcased at Bauma China and engaging with leading manufacturers is an essential step. The future of pipe polishing is bright, efficient, and increasingly intelligent.

Ready to explore cutting-edge pipe polishing technology?

Learn more about Xingtai Xieli Machinery Manufacturing Co., Ltd.'s advanced round pipe metal polishing machines for steel tubes and elevate your production standards:

Visit Xingtai Xieli Today!