Hand-Held Pipe Polishing Machine Exporter A Guide to Quality and Efficiency

In today’s manufacturing and industrial landscape, the finishing of metal products plays a crucial role in determining their aesthetic appeal and longevity. Among various polishing tools available, hand-held pipe polishing machines have gained significant recognition due to their efficiency and versatility. For businesses considering the export of these machines, understanding the market, production quality, and customer needs is paramount.

Understanding Hand-Held Pipe Polishing Machines

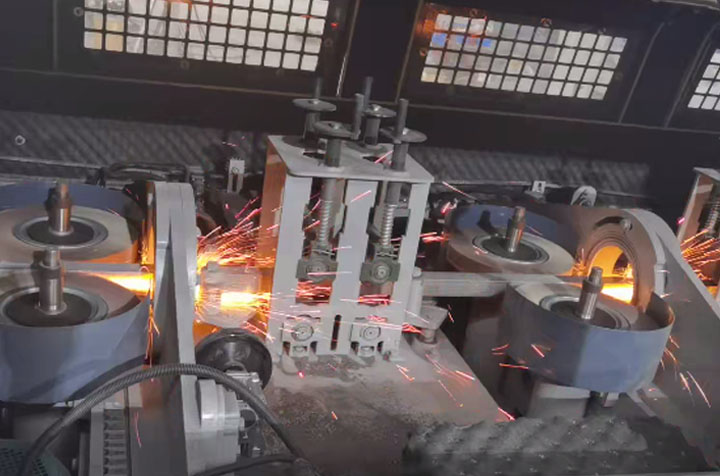

Hand-held pipe polishing machines are specialized tools designed to enhance the surface finish of pipes and tubes, often made from stainless steel, aluminum, and other metals. These machines are commonly used in industries such as construction, automotive, food processing, and petrochemical, where the demand for high-quality, durable, and visually appealing metal products is considerable.

A key advantage of these machines is their portability. Operators can easily maneuver them around different workpieces, making them ideal for both small workshops and large industrial settings. Additionally, they come equipped with various polishing attachments that can accommodate different metal shapes and materials, further increasing their utility.

Quality Standards and Production Considerations

As an exporter of hand-held pipe polishing machines, it is essential to prioritize quality throughout the manufacturing process

. Adhering to international quality standards not only ensures compliance but also strengthens buyer confidence. ISO certifications are a great start, as they demonstrate a commitment to quality management and continuous improvement.Material selection is another critical aspect. The longevity and performance of polishing machines depend heavily on the materials used in their construction. High-grade metals, durable plastic components, and reliable electronic parts are essential to ensure the machines are both robust and efficient.

Additionally, attention to ergonomics in design can significantly enhance user experience. The machines should be lightweight and easy to handle, with comfortable grips and intuitive controls, making them less fatiguing during prolonged use.

hand held pipe polishing machine exporter

Export Market Dynamics

When venturing into the export market, it is important to understand the dynamics of different countries and regions. The demand for hand-held pipe polishing machines often varies depending on local manufacturing capabilities, standards, and industries prevalent in the region. For instance, countries with a growing automotive or construction sector may present lucrative opportunities for exporters.

Conducting market research to identify potential buyers and understanding their specific needs can enable exporters to tailor their products effectively. Engaging with local distributors and participating in international trade fairs can provide valuable insights into market trends. Moreover, maintaining a strong online presence through a professional website and social media platforms can attract global clientele.

Marketing Strategies for Exporters

To stand out in the competitive landscape of hand-held pipe polishing machines, exporters should implement strategic marketing initiatives. Highlighting product features—such as speed, durability, ease of use, maintenance requirements, and after-sales service—can help potential buyers make informed decisions.

Creating informative content, such as instructional videos or detailed product manuals, can also showcase the efficiency of the machines and provide prospects with a sense of reliability. Furthermore, positive customer testimonials can serve as powerful endorsements, building trust and credibility in new markets.

Conclusion

The export of hand-held pipe polishing machines holds great potential in today’s industrial realm. By focusing on quality, understanding market dynamics, and implementing effective marketing strategies, exporters can carve a niche in this promising sector. As global industries continue to prioritize efficiency and quality in manufacturing processes, the demand for high-performing polishing machines will likely remain strong. This presents an excellent opportunity for exporters looking to expand their operations and tap into new markets. The future of the hand-held pipe polishing machine export business appears bright, bolstered by innovation and the ever-increasing need for quality metal finishing solutions.