The Grimax Centerless Grinder Revolutionizing Precision Machining

In the world of precision machining, the Grimax centerless grinder stands out as an exceptional tool designed to enhance efficiency and accuracy. As industries increasingly demand high-quality components, the importance of advanced machining technologies cannot be overstated. The Grimax centerless grinder is an embodiment of innovation, providing manufacturers with a reliable solution for producing high-precision parts with minimal downtime.

Understanding Centerless Grinding

Centerless grinding is a manufacturing process that enables the grinding of cylindrical parts without the need for a central mounting point. Unlike traditional grinding methods, which rely on a workpiece being centered between two points, centerless grinding secures the workpiece through the use of regulating wheels and grinding wheels, allowing for continuous operation. This method is particularly advantageous for producing long, slender workpieces, as it eliminates the complexities associated with centering.

The Grimax centerless grinder excels in this domain, streamlining the entire process and ensuring that components can be machined quickly and efficiently. The machine’s design is tailored to provide excellent stability, thus minimizing vibrations that could adversely affect the precision of the parts produced.

Key Features of the Grimax Centerless Grinder

One of the standout features of the Grimax centerless grinder is its adaptability. With adjustable parameters for wheel speed, feed rate, and workpiece size, operators can easily configure the machine to accommodate a wide variety of jobs. This flexibility makes it ideal for both high-volume production runs and smaller, more specialized projects.

Moreover, the Grimax grinder is equipped with advanced automation features that enhance productivity. Automatic loading and unloading systems reduce manual intervention, allowing for smoother transitions between batches. This capability not only boosts output but also reduces the likelihood of human error, ensuring uniform quality across all produced components.

Precision and Performance

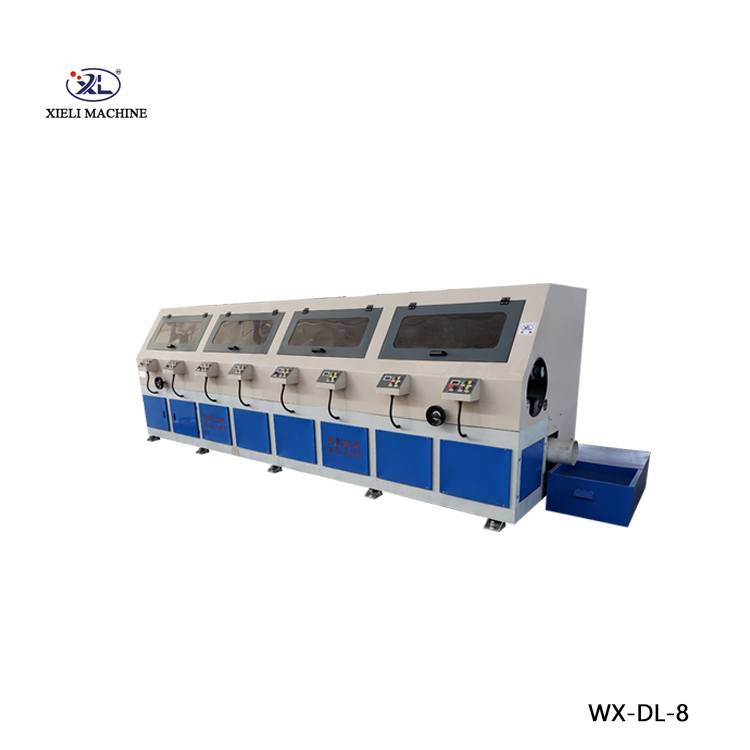

grimax centerless grinder

When it comes to precision, the Grimax centerless grinder delivers outstanding results. The machine is designed to achieve tight tolerance levels, often within microns. This is crucial in industries where precision is paramount, such as aerospace, automotive, and medical device manufacturing. The Grimax’s grinding wheels are engineered to maintain their sharpness over extended periods, ensuring consistent performance and reducing the frequency of wheel replacements.

Furthermore, the grinder’s cooling systems effectively manage heat generated during the grinding process, preserving the integrity of both the workpiece and the grinding wheel. This feature is vital in maintaining the desired surface finish and dimensional accuracy, minimizing post-processing requirements.

Maintenance and User-Friendliness

Another important aspect of the Grimax centerless grinder is its user-friendly design. The machine features intuitive controls and diagnostics, allowing operators of varying skill levels to operate it efficiently. Maintenance is also simplified; easily accessible components make routine checks and adjustments straightforward. Regular maintenance not only prolongs the life of the machine but also ensures that it consistently performs at optimal efficiency.

The Future of Centerless Grinding

As manufacturing continues to evolve with the integration of Industry 4.0 principles, technologies like the Grimax centerless grinder are positioned to play a crucial role. The ability to connect machines to data networks will enable real-time monitoring and analytics, further enhancing productivity and quality control.

In addition to its exceptional performance and user-friendliness, the Grimax centerless grinder is also built with sustainability in mind. The machine is designed to operate with minimal waste and energy consumption, making it an environmentally friendly choice in today's manufacturing landscape.

In conclusion, the Grimax centerless grinder represents a significant advancement in precision machining technology. Its combination of flexibility, precision, and user-centric design positions it as a leader in the field of centerless grinding. As industries strive for greater efficiency and quality, tools like the Grimax grinder will undoubtedly continue to drive innovation and capability in manufacturing processes. Whether it’s for automotive parts, medical devices, or intricate components, the Grimax centerless grinder is poised to meet the diverse needs of modern manufacturing with precision and reliability.