The Importance of GP Centerless Grinders in Precision Manufacturing

In the realm of precision manufacturing, achieving high levels of accuracy and efficiency is of paramount importance. One of the key machines that contribute to this goal is the centerless grinder, specifically the GP centerless grinder. This type of grinder is widely used in various industries for its ability to produce high tolerance components in a streamlined fashion.

The Importance of GP Centerless Grinders in Precision Manufacturing

GP centerless grinders are particularly notable for their versatility and efficiency. They can handle a wide range of materials, including metals, plastics, and composites. This adaptability makes them ideal for various applications, from automotive and aerospace parts to medical devices and electronics. Their ability to grind parts with minimal setup time allows manufacturers to increase productivity while maintaining tight tolerances.

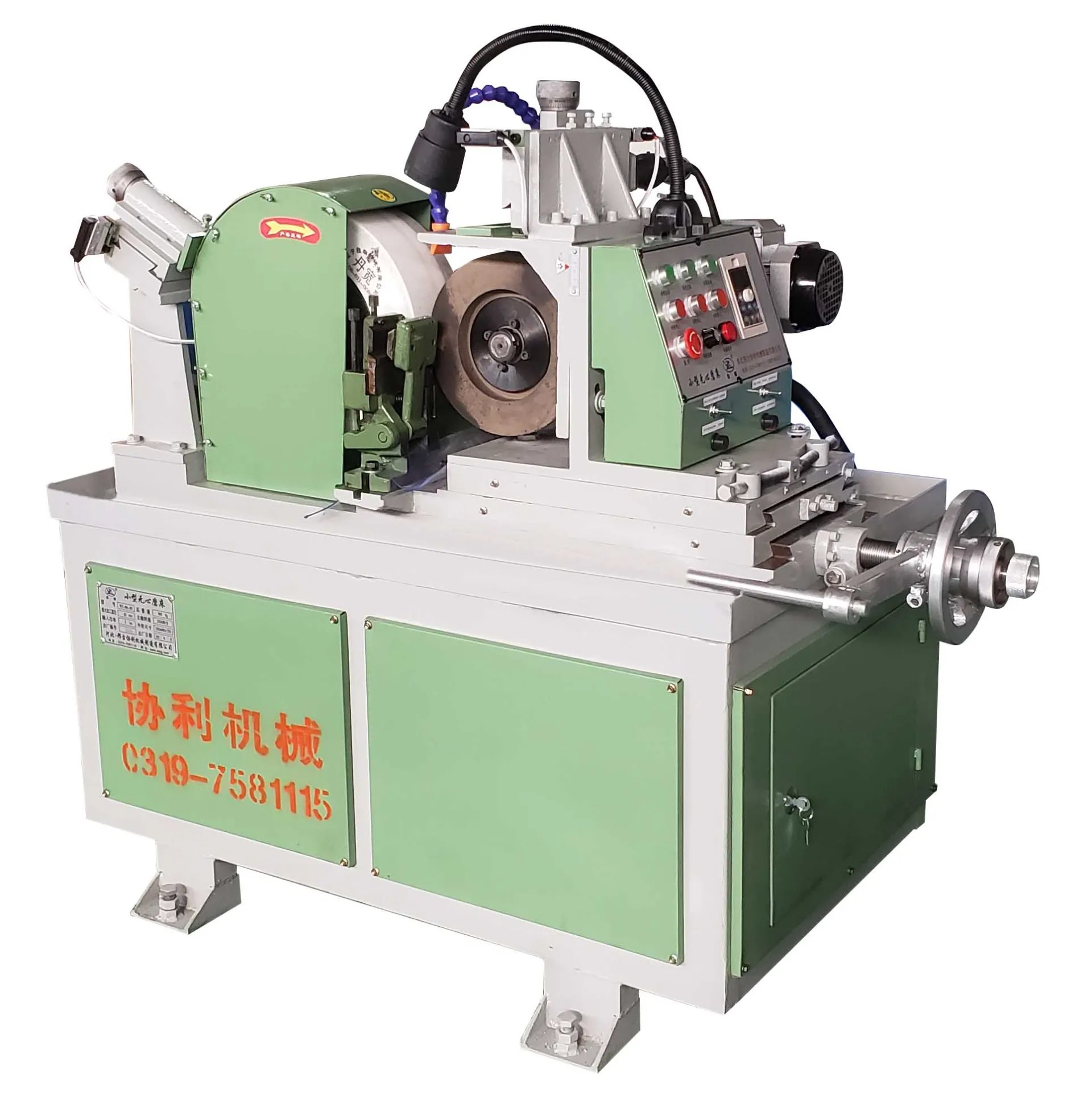

gp centerless grinder

One of the most significant advantages of using a GP centerless grinder is its capacity for high-volume production. This machine can process multiple pieces simultaneously, which significantly reduces cycle time and boosts overall throughput. In industries where time is money, the time-saving aspect of centerless grinding can lead to substantial cost savings and improved competitiveness.

Moreover, GP centerless grinders are designed with advanced technologies that enhance their performance. Many models come equipped with CNC controls, allowing for precise programming of grinding parameters. This technology not only improves accuracy but also enables manufacturers to produce complex geometries that would be difficult or impossible to achieve with manual methods. Additionally, features such as automatic feeding systems and in-process gauging further streamline operations and ensure consistent quality.

Another critical benefit of GP centerless grinders is their ability to produce a superior surface finish. The consistent contact between the grinding wheel and the workpiece, combined with the high cutting speed, results in a smooth, polished finish that often exceeds the requirements for many applications. This aspect is particularly important in industries where surface finish is critical for performance and longevity.

In conclusion, GP centerless grinders play a vital role in the landscape of precision manufacturing. Their ability to deliver high accuracy, increased productivity, and superior surface finishes makes them an essential tool for manufacturers aiming to remain competitive in today’s market. As technology continues to evolve, we can expect further advancements in centerless grinding techniques, further enhancing their capabilities and applications. By investing in high-quality centerless grinders, manufacturers can ensure they meet the demands of a constantly changing industry and continue to thrive in their respective sectors.