GC500 Centerless Grinder The Ultimate Tool for Precision Grinding

In the world of manufacturing and metalworking, precision is key. Among the tools that enable manufacturers to achieve high levels of precision in their operations is the centerless grinder. Specifically, the GC500 Centerless Grinder stands out as an exceptional solution for various grinding needs. This article explores the features, benefits, and applications of the GC500, as well as its significance in production efficiency.

What is a Centerless Grinder?

A centerless grinder is a type of grinding machine used to grind cylindrical workpieces without the need for centers to locate the workpiece. The unique design of a centerless grinder allows the workpiece to be supported by a combination of the grinding wheel, regulating wheel, and work rest. This configuration not only enhances the grinding process's speed but also significantly improves the accuracy of the workpiece dimensions.

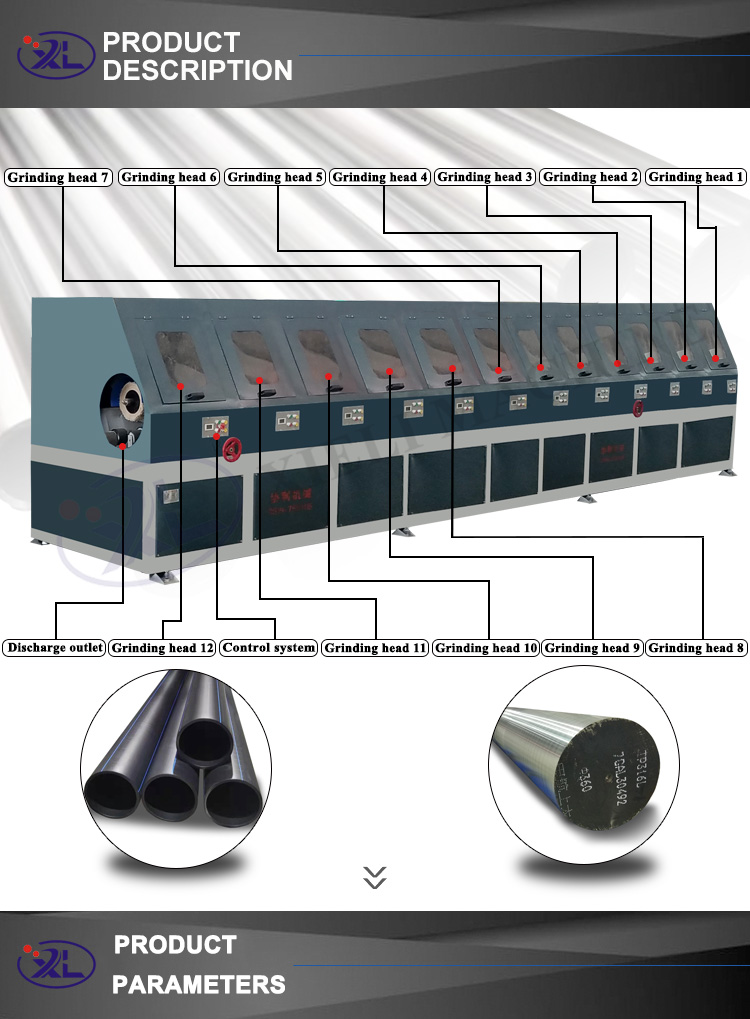

Introducing the GC500 Centerless Grinder

The GC500 Centerless Grinder is engineered for performance and reliability. With its advanced features, this machine can efficiently handle a variety of materials, including steel, aluminum, and various alloys. Its robust construction ensures durability, while its user-friendly interface allows operators of all skill levels to achieve precise results consistently.

Key Features of the GC500

1. Versatile Grinding Range The GC500 is capable of processing a wide range of workpiece sizes and shapes, from small rods to larger components. This versatility makes it an ideal choice for manufacturers looking to optimize their operations.

2. High Accuracy and Efficiency Featuring advanced positioning and alignment systems, the GC500 ensures that every workpiece is ground to exact specifications. This high level of accuracy not only reduces waste but also enhances the quality of the end product.

3. User-Friendly Controls The machine is equipped with an intuitive control panel that allows operators to easily adjust parameters such as speed, feed rate, and depth of cut. This feature facilitates quick setups and minimizes downtime.

4. Enhanced Safety Features Safety is a critical aspect of any manufacturing process. The GC500 includes various safety mechanisms, such as emergency stops and protective guards, ensuring a safe working environment for operators.

5. Energy Efficiency In today’s environmentally conscious world, the GC500 stands out with its energy-efficient design. Consuming less power while delivering high performance, it helps reduce operational costs and minimizes the carbon footprint of production activities.

Benefits of Using the GC500 Centerless Grinder

gc500 centerless grinder for sale product

Integrating the GC500 Centerless Grinder into your manufacturing processes can yield numerous benefits, including

- Increased Productivity By streamlining the grinding process, manufacturers can significantly increase output without compromising quality. The GC500’s high-speed operation allows for faster cycle times, thereby boosting overall productivity.

- Improved Product Quality The precision grinding achieved by the GC500 leads to high-quality finished products. This is especially important in industries such as automotive, aerospace, and medical devices, where tolerances are critical.

- Cost-Effective Operations With its ability to reduce material waste and increase output, the GC500 contributes to more cost-effective manufacturing. Investing in this machine can yield considerable savings in both material costs and labor.

- Adaptability to Different Materials Whether working with metals, plastics, or composites, the GC500 can be configured to accommodate various materials, making it a valuable asset in diverse manufacturing environments.

Applications of the GC500 Centerless Grinder

The GC500 is suitable for a variety of applications, including

- Automotive Parts Manufacturing Ideal for grinding shafts, bushings, and other components that require high precision.

- Medical Device Production Ensures that surgical instruments and implants are manufactured to stringent quality and safety standards.

- Aerospace Components Capable of grinding complex geometries required in the aerospace sector, where precision is paramount.

- General Manufacturing Its versatility makes it applicable in numerous other fields, helping manufacturers achieve their grinding needs efficiently.

Conclusion

The GC500 Centerless Grinder represents a significant advancement in grinding technology, offering unparalleled precision, efficiency, and adaptability. For manufacturers looking to enhance their production capabilities while maintaining high quality, investing in the GC500 is a wise decision. With its robust design and advanced features, the GC500 is not just a tool; it is an essential partner in the quest for excellence in manufacturing.