Flat Surface Polishing Machines Enhancing Finish Quality and Efficiency

In the manufacturing and fabrication industries, achieving a flawless finish on flat surfaces is crucial. Flat surface polishing machines are specialized equipment designed to enhance the surface quality of various materials, including metals, glass, and plastics. These machines are designed to eliminate imperfections, scratches, and oxidation, ensuring that the final product meets high aesthetic and functional standards.

The working principle of a flat surface polishing machine involves the use of abrasive materials and a controlled movement system. As the machine operates, it applies consistent pressure and motion to the surface, gradually refining its texture. This process not only improves the visual appearance of the surface but also increases its resistance to environmental factors, thereby enhancing durability.

Flat surface polishing machines come in various types, each suited for specific applications. Some popular variants include belt polishers, disc polishers, and rotary polishers. Belt polishers, for example, utilize a continuous loop of abrasive material to polish surfaces efficiently, making them ideal for high-volume production environments. On the other hand, disc polishers are often used for more intricate tasks, allowing operators to maneuver around tight corners and complex shapes.

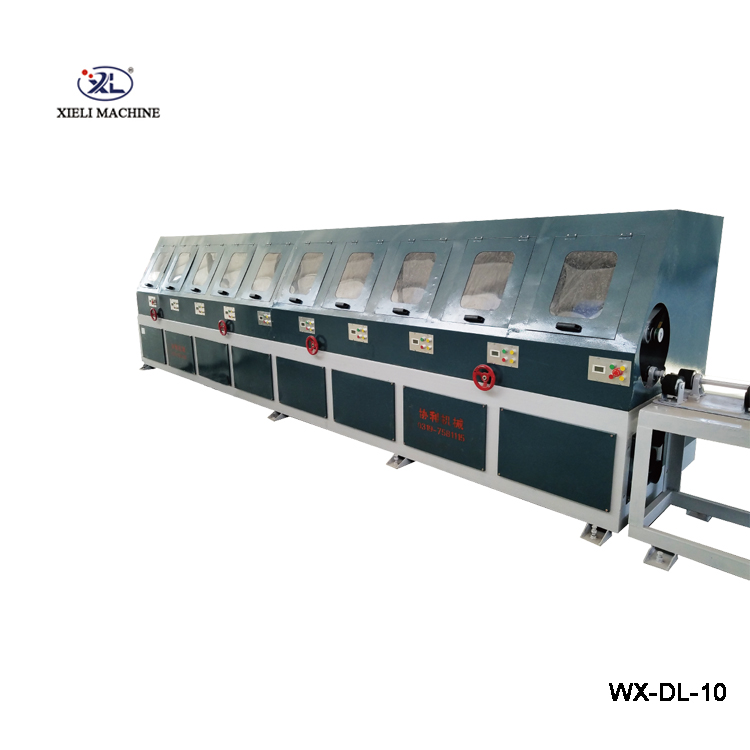

flat surface polishing machine product

One of the key advantages of using flat surface polishing machines is the significant reduction in labor costs and time. Traditionally, polishing was a manual process that required skilled laborers to achieve the desired finish. With modern machines, manufacturers can automate this process, ensuring consistency and precision while freeing up human resources for other critical tasks.

Moreover, recent advancements in technology have led to the development of programmable polishing machines. These machines can be pre-set with specific polishing parameters, allowing for repeatable results across multiple production runs. This not only increases efficiency but also minimizes the risk of human error, ultimately leading to higher product quality.

In conclusion, flat surface polishing machines play a vital role in manufacturing processes where surface quality is paramount. By utilizing these machines, companies can achieve superior finishes, increase production efficiency, and reduce operational costs. As technology continues to evolve, we can expect even more innovations in polishing solutions, further transforming the landscape of manufacturing and fabrication. For industries that demand perfection, investing in high-quality flat surface polishing machines is not just an option; it’s a necessity for maintaining competitive advantage and fulfilling customer expectations.